Automatic exhausting and stopping infusion device with metal micro-flow controller

An automatic exhaust and controller technology, applied in flow control, non-electric variable control, control/regulation system, etc., can solve the problems of large precision deviation and inability to achieve micro-flow effect, so as to prevent blood clots and reduce production difficulty , The effect of prolonging the stop liquid time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

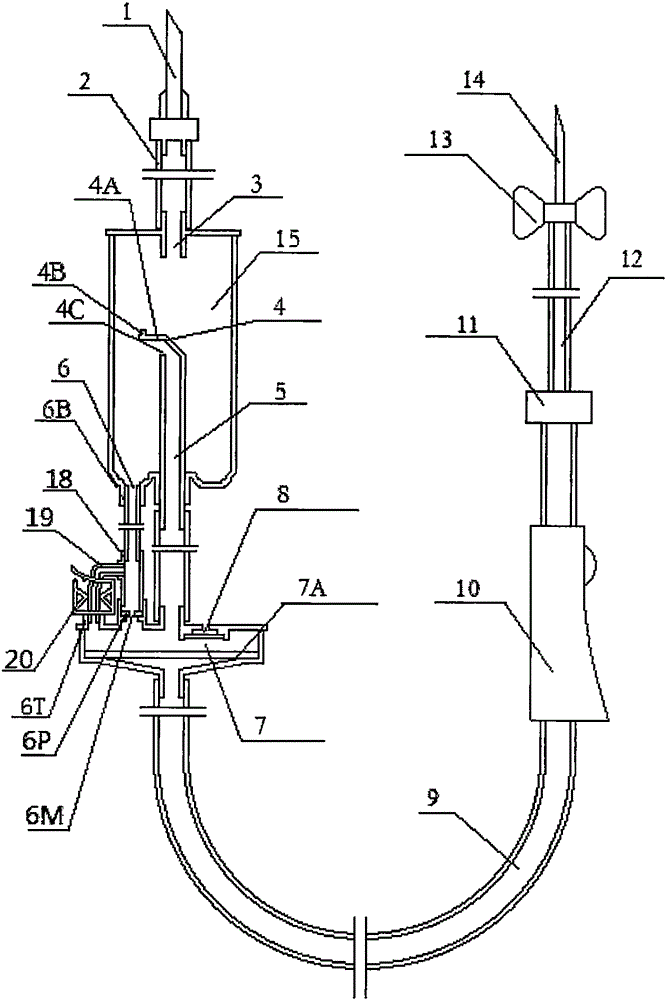

[0020] Such as figure 1 Shown is a central longitudinal sectional view of an auto-venting and liquid-stopping infusion set with a metal microflow controller, the cork piercer 1 is connected to the upper infusion tube 2, the upper infusion tube 2 is connected to the dropper 3, and the dropper 3 Link to each other with dropping funnel cover 15A.

[0021] Insert one in the lower neck of dripping funnel 15 and extend in the cavity of dripping funnel 15, two ends are provided with opening, the exhaust pipe 5 of internal hollow, the side wall upper end of exhaust pipe 5 has an exhaust hole 4C , The position of vent hole 4C is located between 1 / 2~2 / 3 of the high pipe of dropping funnel 15. The upper cover surface 4 of the exhaust pipe 5 is a slope plate facing away from the direction of the exhaust hole 4C, the upper cover surface 4 is airtight, and the junction line between the upper cover surface 4 and the exhaust pipe 5 Among them, select the section directly above the exhaust h...

Embodiment 2

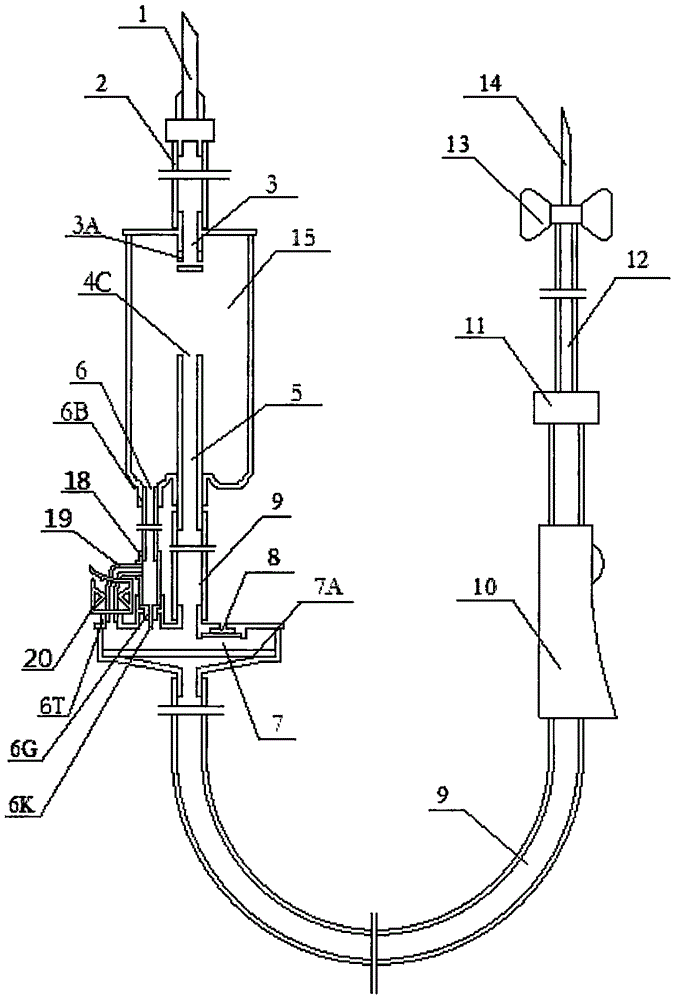

[0034] Such as figure 2 Shown is a central longitudinal sectional view of an auto-venting and liquid-stopping infusion set with a metal microflow controller, the cork piercer 1 is connected to the upper infusion tube 2, the upper infusion tube 2 is connected to the dropper 3, and the dropper 3 Link to each other with dropping funnel cover 15A. A nozzle 3A is installed at the lower end of the dropper 3, and the lower end of the nozzle 3A is sealed, and the side portion has more than one spout towards the sidewall of the dripping funnel 15.

[0035] Insert one in the lower neck of dripping funnel 15 and extend in the cavity of dripping funnel 15, two ends are provided with opening, the exhaust pipe 5 of internal hollow, the side wall upper end of exhaust pipe 5 has an exhaust hole 4C , The position of the exhaust hole 4C is located between 1 / 2~2 / 5 of the height of the dropping funnel. The tube height of dropping funnel 15 is higher than 5CM.

[0036] From the lower bracket o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com