A slurry-driven stirring flotation equipment with self-adjusting slurry and self-defoaming functions

A self-adjusting slurry and stirring technology, applied in flotation, solid separation, etc., can solve the problems affecting the flotation effect, excessive turbulence in the flow field, and particle shedding, so as to improve the spray impact force, generate stability, and improve The effect of spawn rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

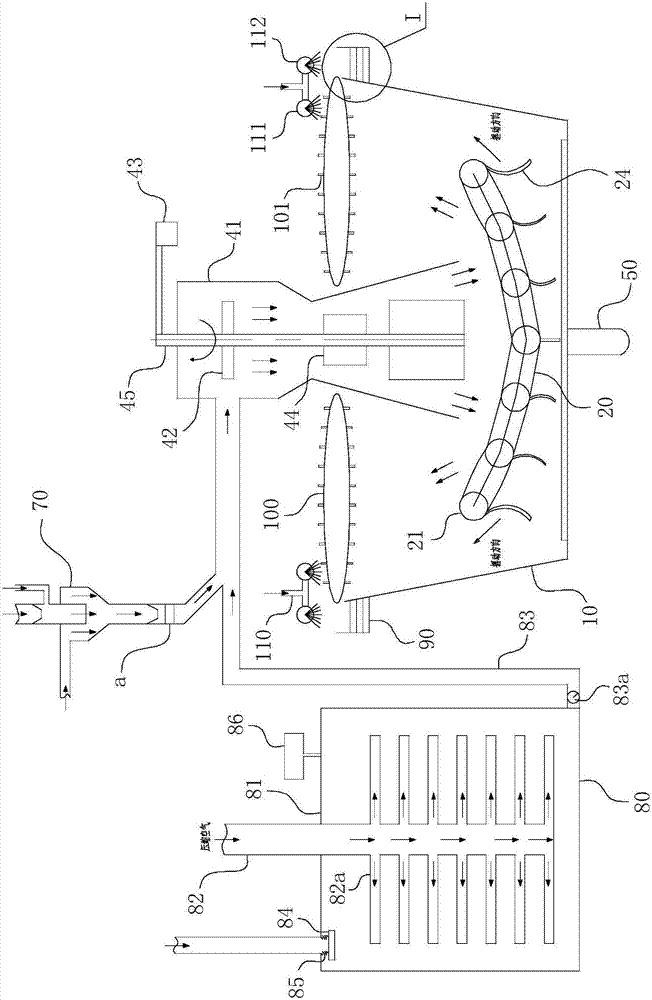

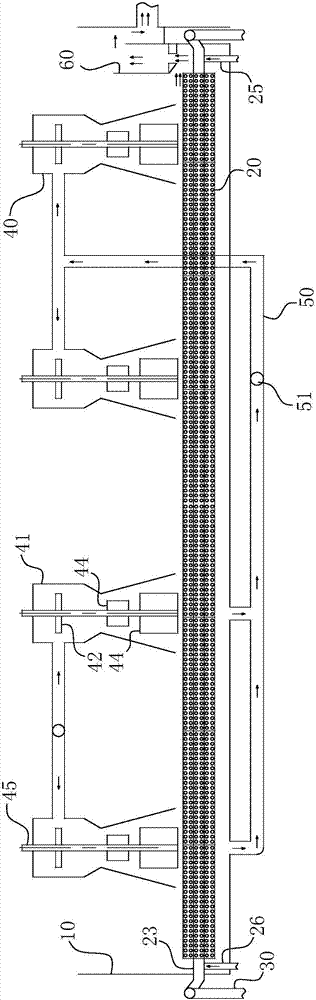

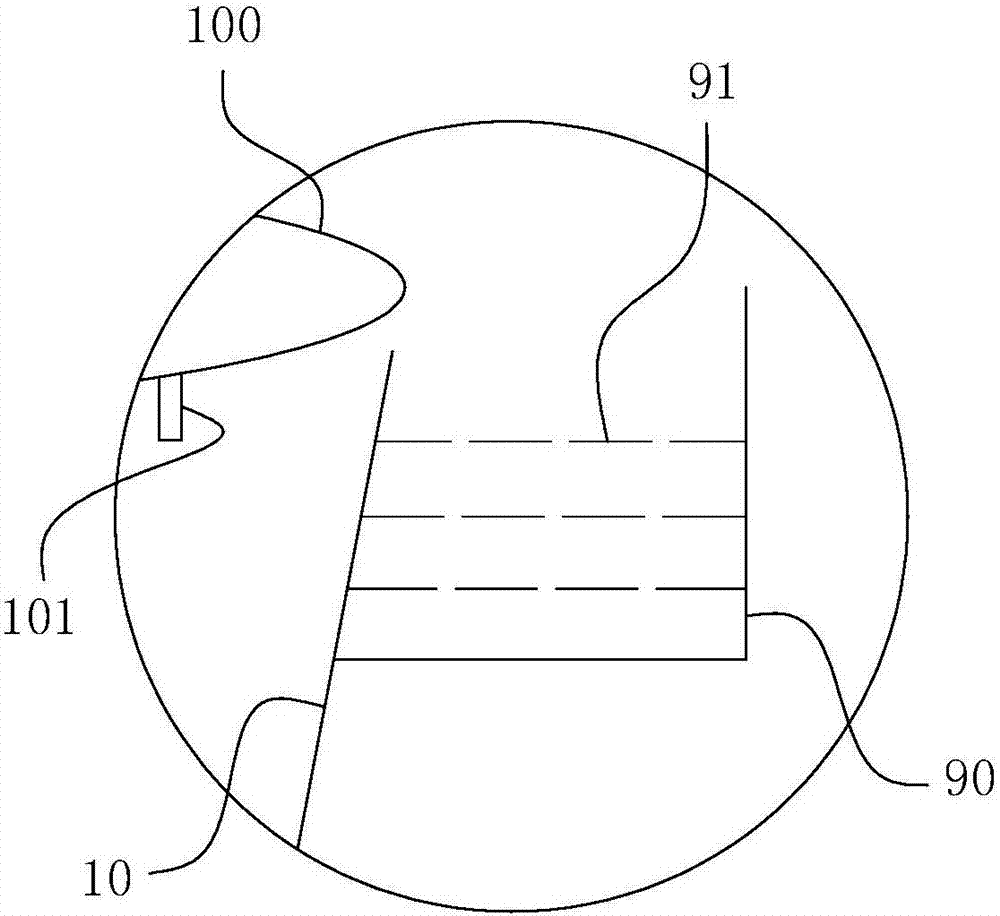

[0048] For ease of understanding, combined here Figure 1-7 , the specific embodiments of the present invention are further described as follows:

[0049] The specific components of the present invention are divided into several major modules, including: flotation cell 10, flotation feeding pressurized buffer tank 80, double sleeve jet assembly 70, driving stirring mechanism 40, microbubble generating bed 20, circulation type Bubble scraping assembly 100, clean water spraying assembly 110 and tailings box. Describe them one by one below:

[0050] 1. Flotation feeding pressure buffer tank

[0051] Its structure is as figure 1 As shown, a sealed cylindrical tank body 81 is included, and a compressed air pipe 82 is coaxially arranged vertically in the tank body 81 . The air inlet at the top of the compressed air pipe 82 is connected to an external air source, while the air outlet section at the bottom is distributed in a fork shape or in a layered branch-like arrangement with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com