A four-sided bottom edge edging machine

An edge grinding machine and bottom edge technology, which is applied in the direction of grinding frames, grinding machine parts, and machine tools suitable for grinding workpiece edges, etc., can solve problems such as high management costs, troubles for glass manufacturers, and increased investment. , to achieve the effect of improving economic efficiency, using safety and operating stability, and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

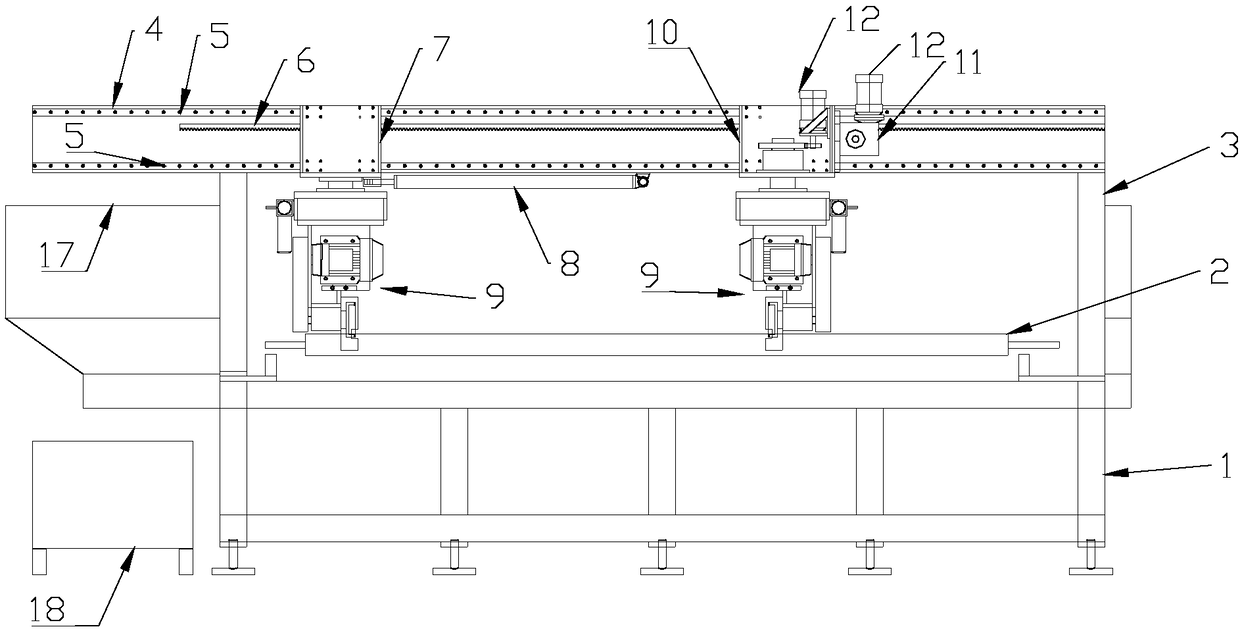

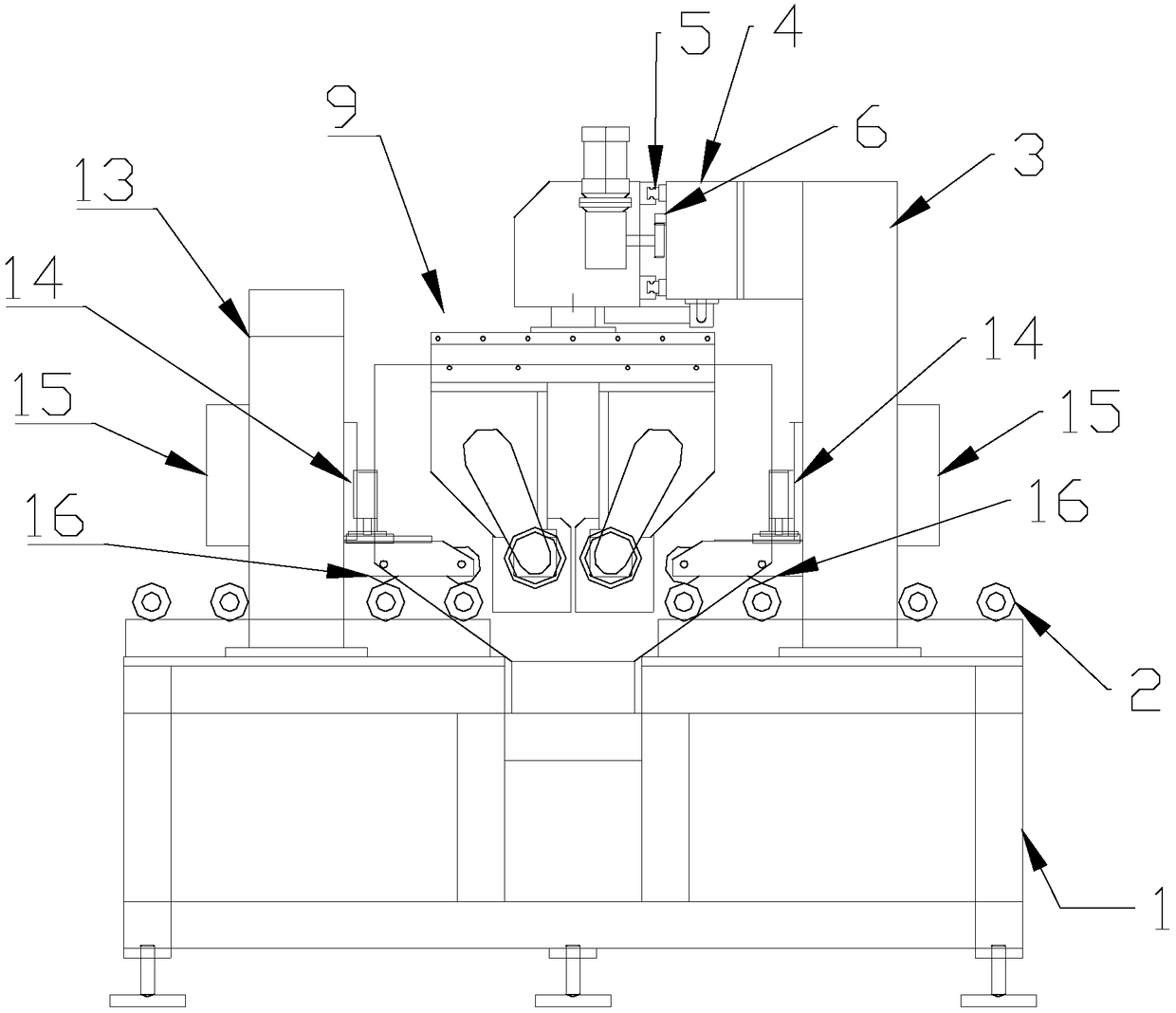

[0014] see Figure 1-2 , a four-sided bottom edge edging machine, including a frame body 1, a roller table 2, a beam component group, a pressing component group and a grinding head motor component assembly 9, and the beam component group includes a column 3, an upper beam 4, Linear guide rail 5 and rack 6, the pressing component group includes servo motor 12, reducer 11, gear, linear guide rail, cylinder 8, pressure roller and electrical controller 15, and roller table 2 and column 3 are arranged on frame body 1 , the upper beam 4 is installed on the column 3, the linear guide rail 5 and the rack 6 are installed in front of the upper beam 4, the cylinder 8 is installed under the upper beam 4, and the fixed grinding head frame 7 and the mobile grinding head frame 10 are arranged on the linear guide rail 5 , the cylinder 8 is connected with the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com