A slicing method for 3D printing

A 3D printing and slicing technology, which is applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of not considering material adhesion, etc., to increase strength, increase equipment operation difficulty, and strong regularity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

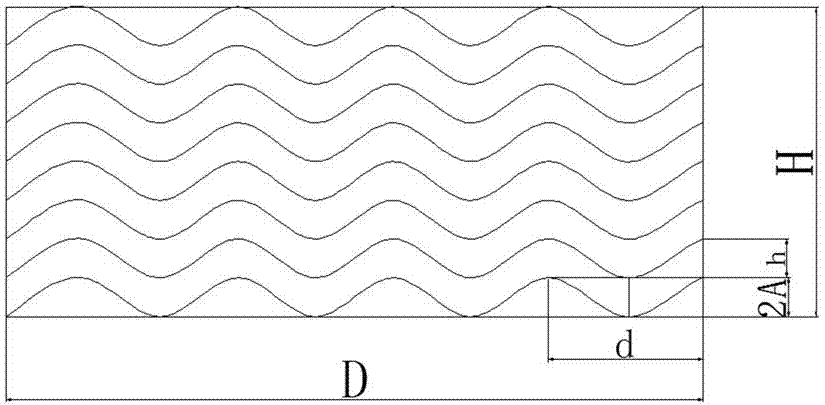

[0028] Embodiment one: see figure 2 Shown, a kind of slicing method of 3D printing comprises the following steps:

[0029] (1) Use computing software to build a three-dimensional model of the product;

[0030] (2) Carry out slicing processing on the grid model file, divide the model into several slices along the vertical direction, and divide the slices into curved surfaces. The boundary line is a sinusoidal curve;

[0031] (3) Print layer by layer according to the layer information obtained in step (2).

[0032] See attached figure 2 , the maximum width of the model is D, the height of the model is H, the amplitude of the sine curve or cosine curve is A, the period is d, and the layer thickness is h. When H / D﹥1, A﹥2h, d﹥4h, When H / D≤1, h≤2A≤2h, 2h≤d≤4h.

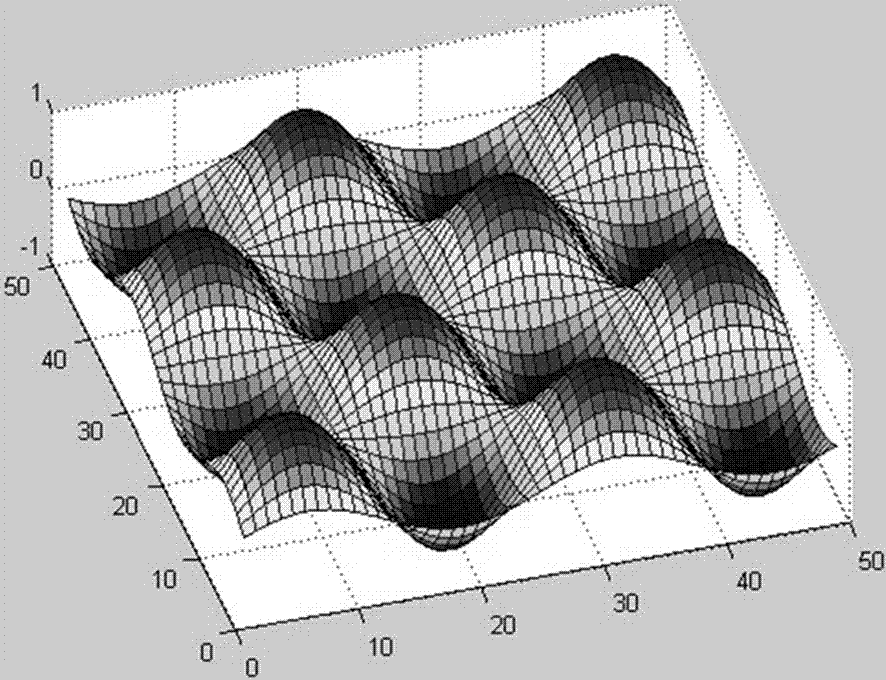

[0033] See attached image 3 , is a schematic diagram of the surface cut distribution of slices in the embodiment. It can be seen from the same figure that in this embodiment, the peaks and valleys formed by the sin...

Embodiment 2

[0035] Embodiment 2: A slicing method for 3D printing, the steps are similar to Embodiment 1, wherein, refer to the attached Figure 4 As shown, it is the contour map of the slice. The dark part represents the peak value, and the light part represents the valley value. In the bottom surface projection of the printed object, the size of each direction is different, and the slices are sliced in different directions with different periods.

Embodiment 3

[0036] Embodiment 3: A slicing method for 3D printing. Part of the slices in the model are composed of curved layers, and some of the slices are composed of plane layers. One side of the slice of the connecting piece is a curved surface, and the other is a plane. as attached Figure 5 As shown, when printing, the base layer can be printed on the bottom layer first, and then the flat slice can be printed in the normal way. When printing in this way, although the printing mechanism moves according to the plane, the final actually generated surface is in the shape of a curved surface. According to the shape and strength requirements of the model, choose different slice matching forms to increase the printing speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com