A microbial carrier with a core-shell structure and a floating-sinking method for treating polluted water

A microbial carrier, core-shell technology, applied in granular microbial carrier treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of expensive devices and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

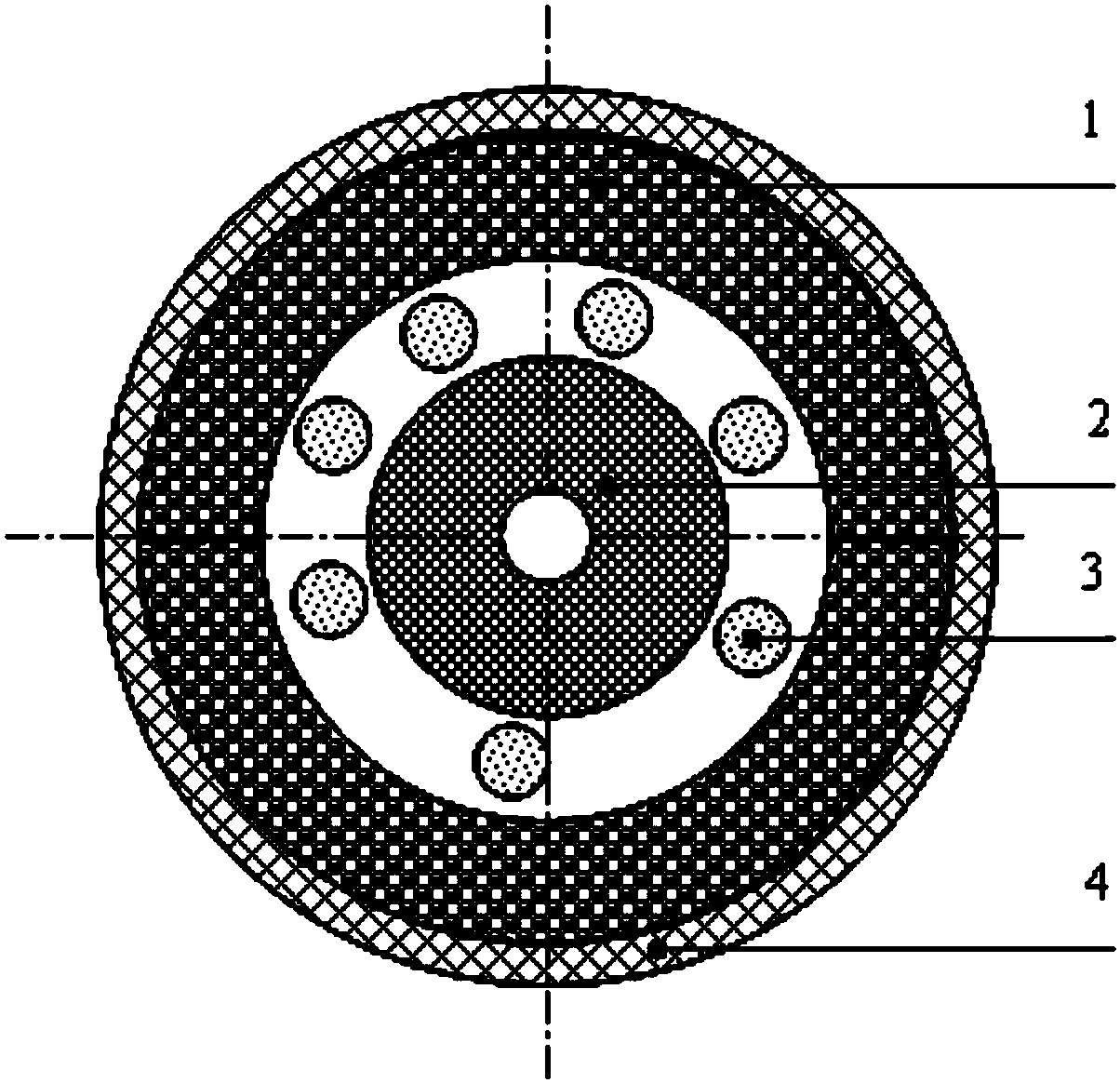

[0032] Such as Figure 1-2 As shown, a microbial carrier with a core-shell structure described in the embodiment of the present invention includes an outer shell 1, a spherical core body 2 and a protective net cover 4, and the outer shell 1 and the spherical core body 2 are both porous microbes. Gap structure, the outer casing 1 has undergone aerobic microbial culture implantation curing treatment, the spherical core body 2 has undergone anaerobic microbial cultivation implantation curing treatment, the spherical core body is placed in the outer casing, and The outer shell 1 is covered with a layer of protective mesh 4 to prevent the carriers from colliding with each other and rubbing against the side walls.

[0033] Further, a number of foamed plastic balls 3 are placed between the core body 2 and the outer shell 1 to adjust the specific gravity, and ensure that the core body and the outer shell are arranged concentrically. Foam plastic balls are uniformly distributed betwee...

Embodiment 2

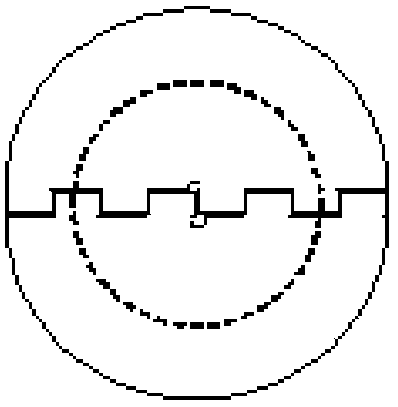

[0043] In the manufacturing method of the microorganism carrier with core-shell structure described in this embodiment, the outer shell is divided into two half-shells, which are formed by butting the two half-shells. When the two half-shells are made, the edge of the butt joint It needs to be made in the form of snap buttons for easy fastening and bonding.

[0044] The two half-shells of the outer shell and the core body are respectively kneaded and mixed from clay, activated carbon particles, carbon fiber silk raw materials, organic fibers and inorganic fiber silk, and then stamped and formed, dried in the shade, and then sintered in a protective atmosphere forming.

[0045] The two half-shells of the outer shell and the spherical core have different formula ratios due to different functions. For the outer shell and the core, please give the preferred formula ratios respectively.

[0046] Control the vaporization of the organic fibers to form pores during the sintering pro...

Embodiment 3

[0052] The floating-sinking method for treating polluted water bodies described in this example uses at least two layers of porous and microporous carriers, the outer porous and microporous structures are treated with aerobic microbial culture and implantation, and the inner porous and microporous structures are The pore structure is treated with anaerobic microbial culture implantation bed maturation, so that when the carrier sinks to the bottom of the water body, the anaerobic bacteria digest ammonia nitrogen to generate nitrogen and store it in the porous micropore structure of the carrier, and the specific gravity of the carrier decreases and floats upward to the water surface. When the carrier surfaced, the aerobic bacteria on the outer layer of the carrier began to digest the organic pollutants in the water, while keeping the anaerobic bacteria inside the anaerobic environment; when the carrier floated on the water surface, the porous micropore structure outside the carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com