Method for degrading inorganic malodorous pollutant ammonia gas by ultraviolet light illumination

A technology of ultraviolet light and pollutants, which is applied in the field of photocatalytic degradation of pollutants, can solve the problems such as the degradation ability needs to be improved, the chemical bonds are easy to break, and the load is not firm, so it is beneficial to popularization and application, the operation method is simple and easy, and the degradation experiment The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for degrading inorganic odor pollutant ammonia gas by ultraviolet light irradiation, the specific steps are:

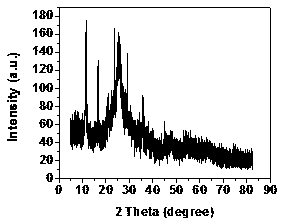

[0045]1) In a clean beaker, take 100 mL of nano-titanium dioxide sol solution (quantitatively unchanged) and 100 mL of copper chloride solution in a volume ratio of 1:1, and spray them evenly on the glass fibers successively. After the spraying is completed, put the sprayed glass fiber in a high-temperature furnace with a heating gradient of 5 °C / min from room temperature to 180 °C, and keep it for 12 hours. After closing the high-temperature furnace, wait for the temperature to cool to room temperature. spare in the device;

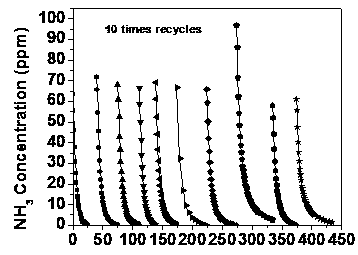

[0046] 2) the sheet-like photocatalytic material obtained is placed between the ultraviolet sterilization lamps in the photocatalytic reactor of the self-designed purifier device, and there are 28 8W ultraviolet lamps in the reactor (ultraviolet lamp Philips, the dominant wavelength is 254nm), and the reactor cabin is made of ma...

Embodiment 2

[0060] The specific experimental method is basically the same as in Example 1 of this part, except that the copper chloride solution is changed to a copper bromide solution.

Embodiment 3

[0062] The specific experimental method is basically the same as in Example 1 of this part, except that the copper chloride solution is changed to a copper sulfate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com