Movable type high-performance integrated machine for sludge treatment

A technology of sludge treatment and integrated machine, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of poor sealing of the whole machine, large floor area, and overflowing mud, and achieve good compressive strength and automation High and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

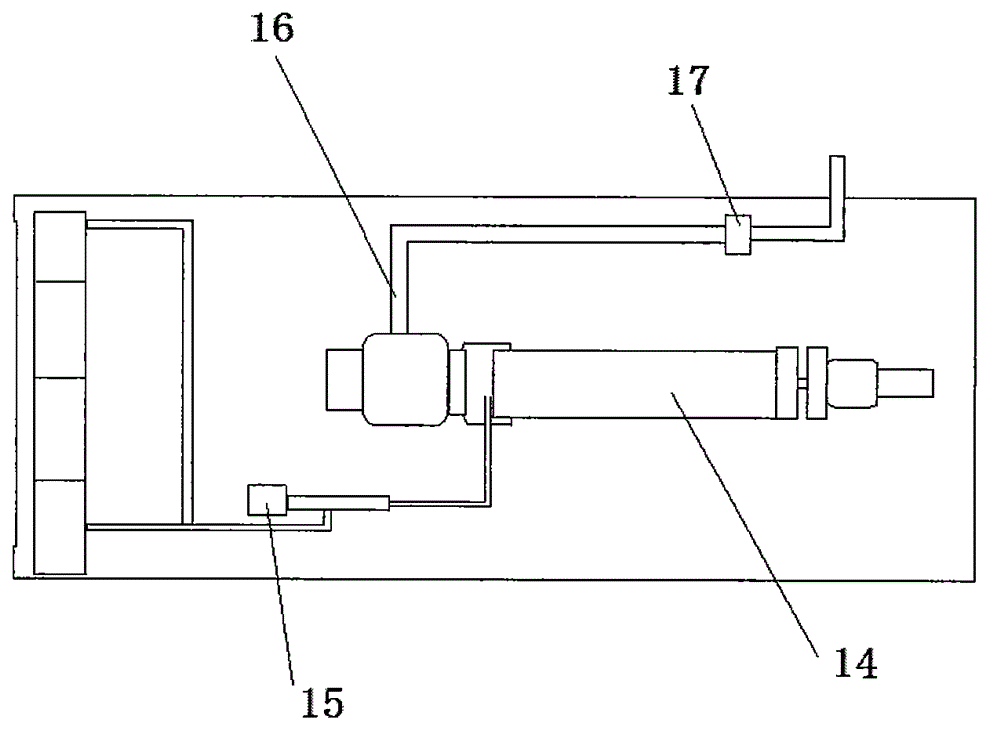

[0015] A mobile high-efficiency sludge treatment machine, such as figure 1 As shown, the all-in-one machine is composed of a screw-stacking sludge deep dewatering machine 14, a dosing device 15 and a sludge conveyor 16; The inlet of dehydrator 14 links to each other;

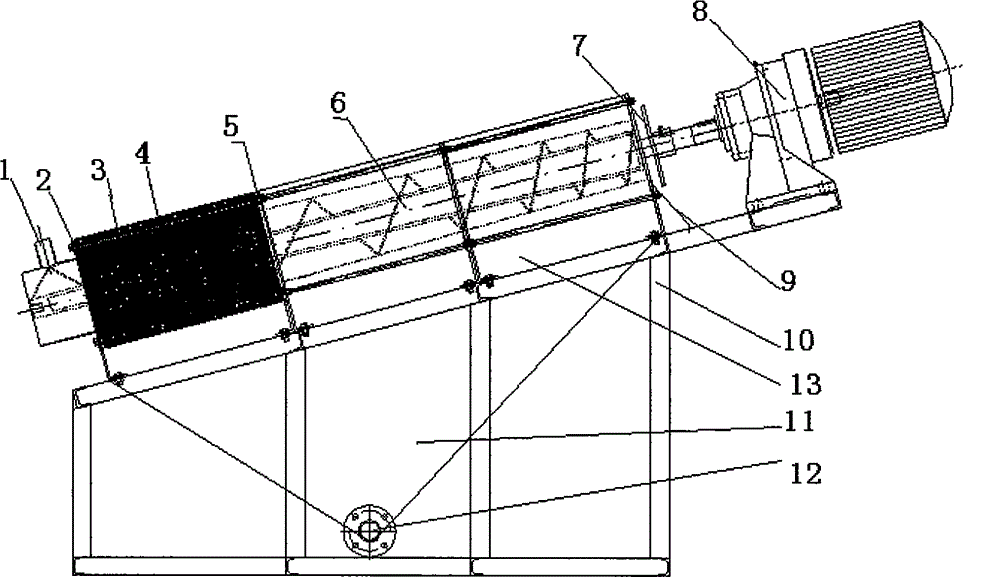

[0016] Such as figure 2 As shown, the structure of the stacked screw type sludge deep dewatering machine 14 is as follows: the variable diameter movable and fixed ring 3 is fixed on the equipment shell 13 through the fixing bolt 4 and the fixing plate 5, and a groove is arranged at one end of the screw shaft 6, which is connected with the equipment The built-in cylindrical boss at one end of the shell 13 is fitted, the screw shaft 6 is connected with the geared motor 8 at the other end and fixed on the equipment support 10 together, the feed port 1 is set at the front end of the screw shaft 6, and the discharge port 9 is set at the At the rear end of the screw shaft 6 , the pressing plate 2 is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com