A method for passivating and cooling anthracite and its integrated device

A technology of anthracite and cooling gas, applied in coke cooling, solid fuel, fuel, etc., can solve the problems of unsatisfactory passivation effect of dry distillation pyrolysis anthracite, low thermal efficiency of the device, no recycling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

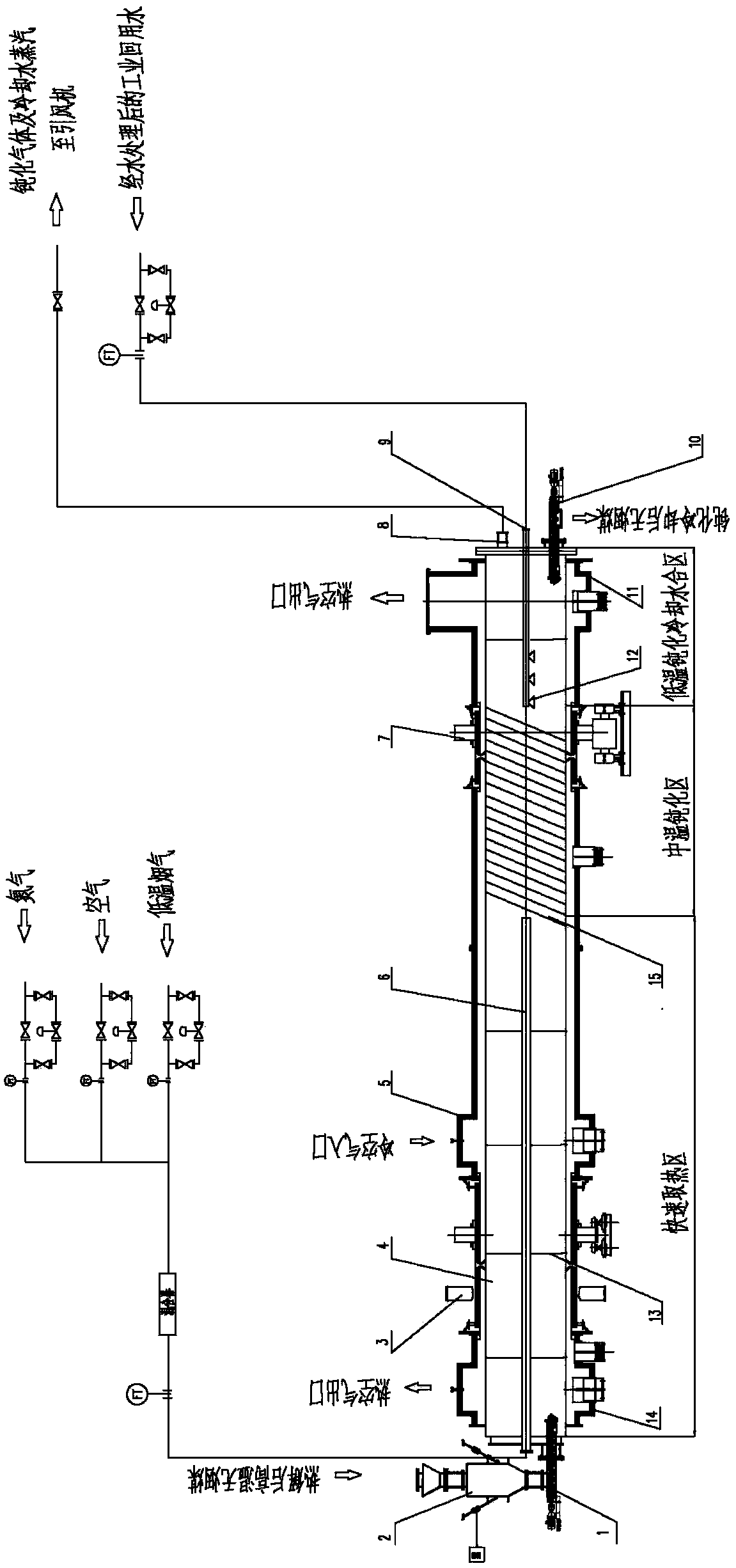

[0049] Embodiment 1, the method for passivation cooling anthracite:

[0050] A method for passivation cooling anthracite, comprising the steps of:

[0051] (1) cooling the pyrolyzed anthracite at 550°C to 250°C to obtain pretreated anthracite;

[0052] (2) reacting the anthracite pretreated in step (1) with an inert gas to activate the anthracite with oxygen to form a medium-temperature passivated anthracite at 220° C., wherein the inactive gas is flue gas and air at 130° C. or a mixture of nitrogen, the volume fraction of oxygen in the inert gas is 20%;

[0053] (3) adopt the industrial reuse water of water treatment to carry out cooling and hydration reaction simultaneously to the medium temperature passivation anthracite of described step (2), obtain the low temperature passivation anthracite of 60 ℃, the water content of this anthracite is 12% (mass fraction) .

Embodiment 2

[0054] Embodiment 2, the method for passivation cooling anthracite:

[0055] A method for passivation cooling anthracite, comprising the steps of:

[0056] (1) cooling the pyrolyzed anthracite at 600°C to 220°C to obtain pretreated anthracite;

[0057] (2) react the anthracite pretreated in step (1) with an inert gas to activate the anthracite with oxygen to form a medium-temperature passivated anthracite at 150° C., wherein the inactive gas is flue gas and air at 180° C. Or a mixture of nitrogen, the volume fraction of oxygen in the inert gas is 8%;

[0058] (3) adopt the industrial reuse water of water treatment to carry out cooling and hydration reaction simultaneously to the medium temperature passivation anthracite of described step (2), obtain the low temperature passivation anthracite of 40 ℃, the water content of this anthracite is 6% (mass fraction) .

Embodiment 3

[0059] Embodiment 3, the method for passivation cooling anthracite:

[0060] A method for passivation cooling anthracite, comprising the steps of:

[0061] (1) cooling the pyrolyzed anthracite at 580°C to 220°C to obtain pretreated anthracite;

[0062] (2) react the anthracite pretreated in step (1) with an inert gas to activate the anthracite with oxygen to form a medium temperature passivated anthracite at 180° C., wherein the inactive gas is flue gas and air at 180° C. Or a mixture of nitrogen, the volume fraction of oxygen in the inert gas is 15%;

[0063] (3) adopt the industrial reuse water of water treatment to carry out cooling and hydration reaction simultaneously to the medium temperature passivation anthracite of described step (2), obtain the low temperature passivation anthracite of 50 ℃, the water content of this anthracite is 8% (mass fraction) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com