Vanadium-containing steel for motor train unit axle and production method and heat treatment process thereof

A technology for axle steel and production method, which is applied in the field of alloy steel, can solve the problems of high limit of improvement in fatigue resistance, inability to meet the requirements of axle toughness of EMUs, and limited improvement in fatigue resistance of axle steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below, which is a preferred embodiment among various implementations of the present invention.

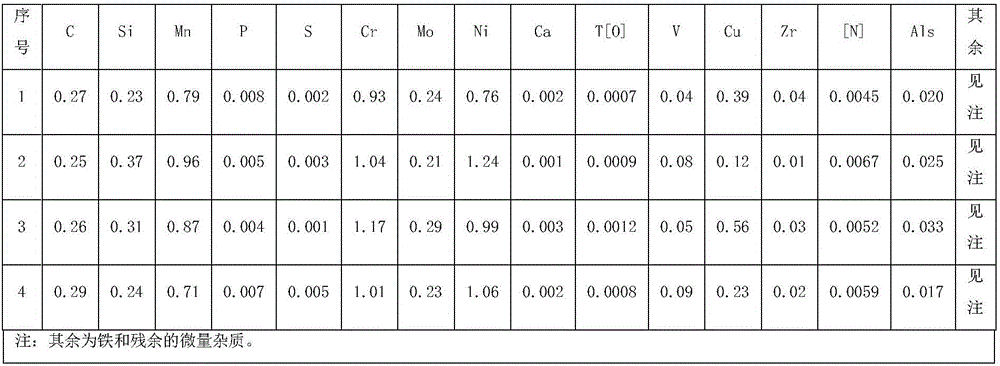

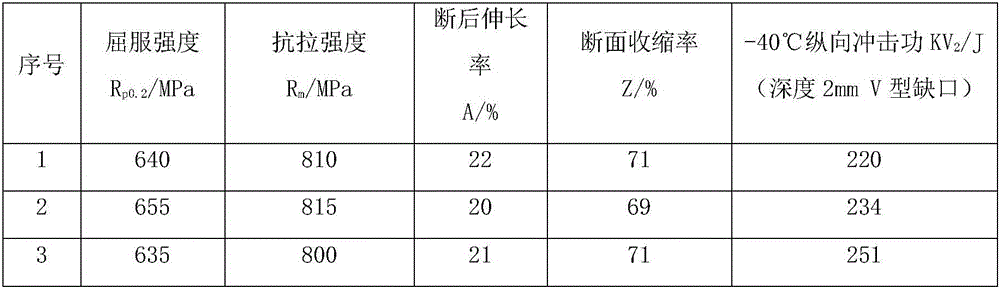

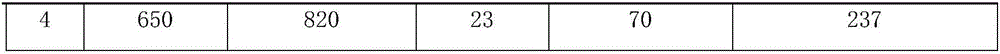

[0033] In a preferred embodiment, a vanadium-containing EMU axle steel comprises components C: 0.24-0.30, Si: 0.20-0.40, Mn: 0.70-1.00, Cr: 0.90-1.20, Ni: 0.70 by weight percentage ~1.30, Mo: 0.20~0.30, Cu: 0.10~0.60, Zr: 0.01~0.04, V: 0.05~0.10, Ca: 0.001~0.005, P≤0.010, S≤0.008, [N]: 0.0040~0.0070, T [O]≤0.0015, Als: 0.015~0.045, the rest is Fe and other unavoidable impurities; the structure of the steel is tempered sorbite + a small amount of lower bainite, in which, the tempered sorbite near the surface of the axle is The content is 100%, and the content of tempered sorbite at the 1 / 2 radius of the axle is 80-90%; its longitudinal mechanical properties reach: R m : 750MPa~900MPa, R eL or R p0.2 ≥600MPa, A≥18%, Z≥40%, -40℃ longitudinal impact absorption KV 2 ≥150J; fracture toughness K Q Value ≥ 120MPa·m 1 / 2 ; The rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com