Automatic production device for metal gold imitation zipper coloring

A kind of production equipment and gold imitation technology, which is applied in metal material coating technology, sliding fastener components, clothing, etc., can solve the problems of high production cost, poor production environment, large material consumption, etc., and achieve convenient operation and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

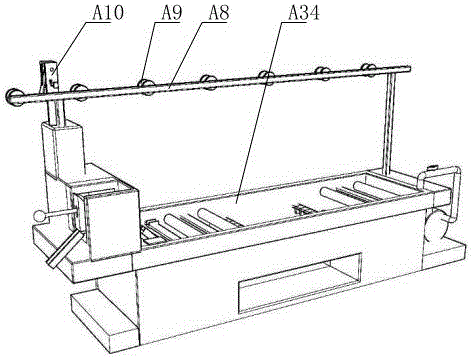

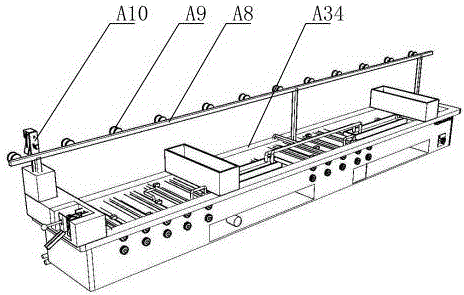

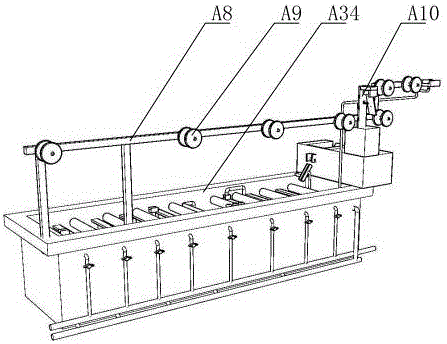

[0052] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0053] Such as Figure 1-Figure 15 As shown, the metal imitation gold zipper coloring automatic production equipment of the present embodiment comprises successively connected degreasing device, chemical polishing device and imitation gold coloring device, and the structure of degreasing device is: comprise degreasing box A34, degreasing box A34 There are four tanks separated by the partition plate A35. From left to right, there are the first degreasing and cleaning tank A37, the degreasing chemical tank A38, the second degreasing and cleaning tank A39 and the third degreasing and cleaning tank A40. The top of the tank is equipped with degreasing driving wheel A11, and the two ends of each degreasing driving wheel A11 are supported and installed by degreasing stainless steel bearing A12 and degreasing plastic rolling ring A15, and the degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com