Flue gas waste heat recovery device capable of changing super conductive tube rapidly

A technology of superconducting heat pipes and flue gas waste heat, which is applied in indirect heat exchangers, lighting and heating equipment, and steam generation methods using heat carriers, etc. Poor effect and other problems, to achieve the effect of convenient disassembly and replacement of heat pipes, small footprint, and fast replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

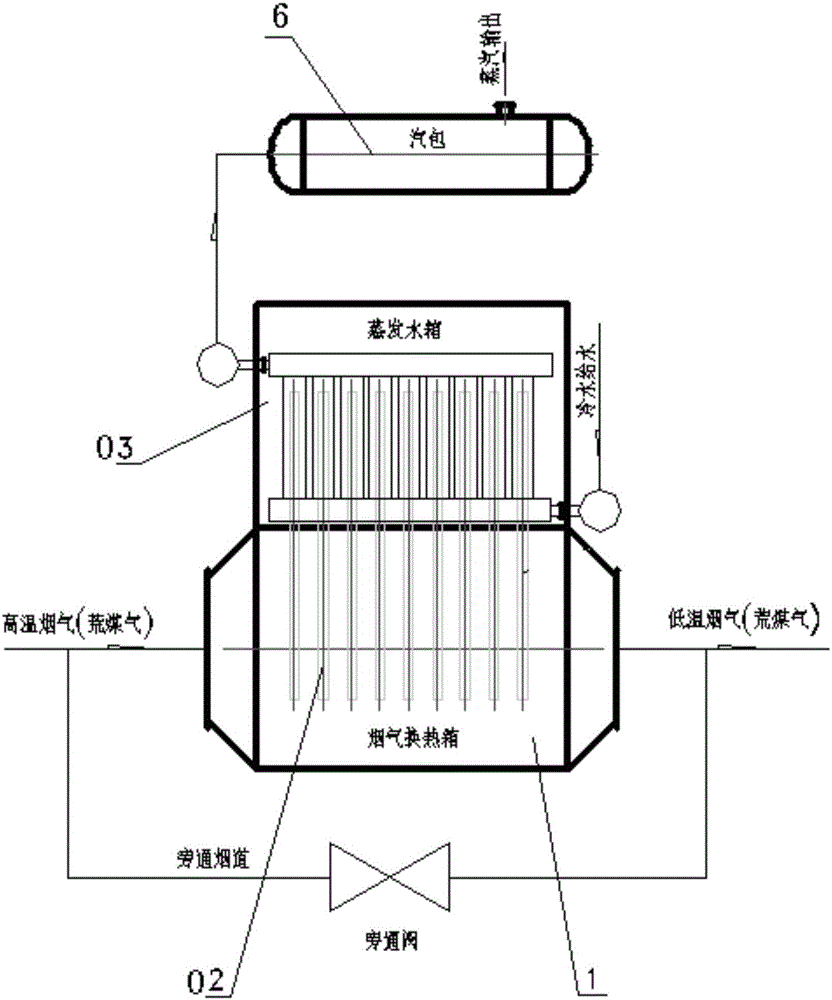

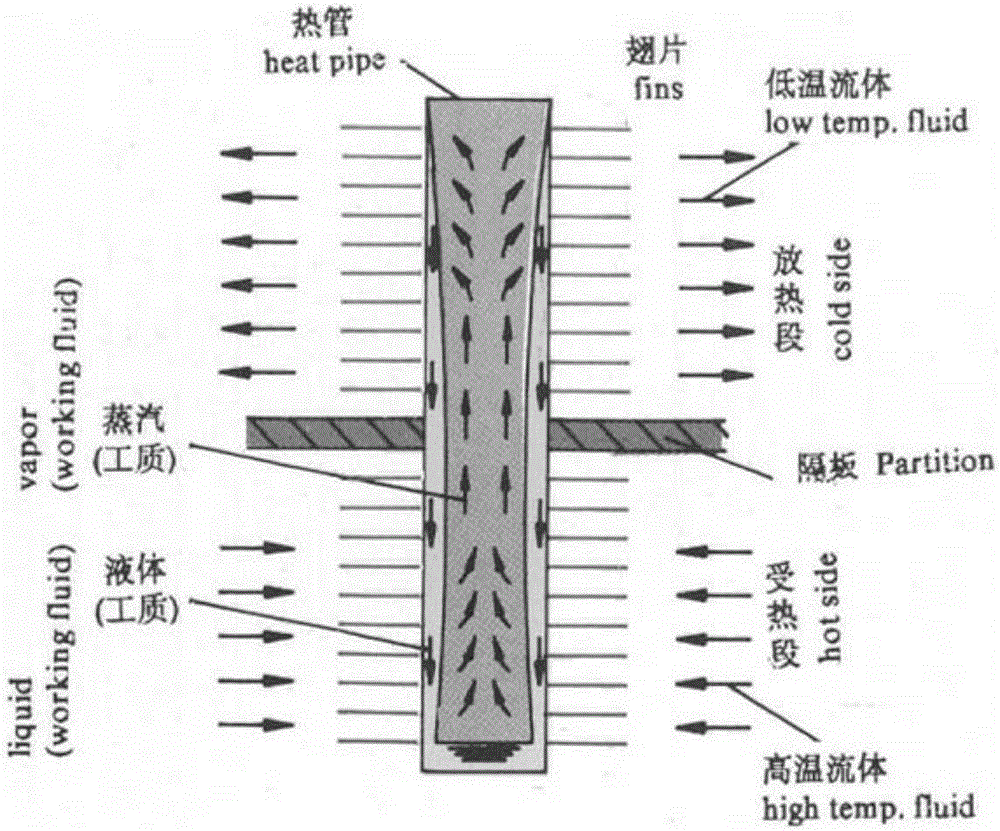

[0021] combined with figure 1 , a flue gas waste heat recovery device for quick replacement of superconducting heat pipes, which includes a flue gas heat exchange box 1, a superconducting heat pipe 02, an evaporation water tank 03 and a steam drum 6; the flue gas heat exchange box 1 is used for waste heat recovery, The lower part of the superconducting heat pipe 02 is installed in the flue gas heat exchange box 1, and the upper part of the superconducting heat pipe 02 is installed in the evaporation water tank 03. The superconducting heat pipe 02 is used to absorb the waste heat of the flue gas heat exchange box and transfer the waste heat to the evaporation water tank 03; the evaporating water tank 03 is installed above the flue gas heat exchange box 1 to absorb the heat energy of the superconducting heat pipe 02, so that the water in the water tank becomes steam; the evaporating water tank 03 is also connected with a steam drum 6 through a pipeline; The bag 6 is used to stor...

specific Embodiment 2

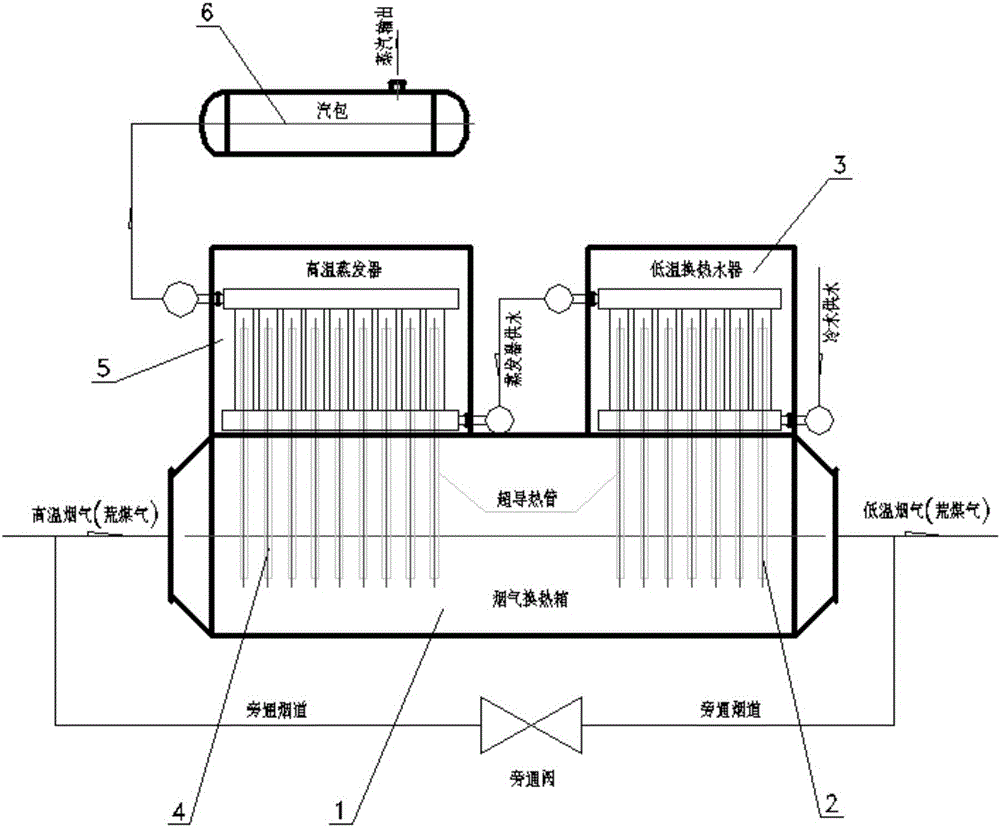

[0022] further combined with figure 2 , a superconducting heat pipe quick replacement flue gas waste heat recovery device, which includes a flue gas heat exchange box 1, a superconducting heat pipe, an evaporation water tank and a steam drum 6; the superconducting heat pipe includes a low-temperature section superconducting heat pipe 2 and a high-temperature section Two parts of superconducting heat pipe 4; described evaporating water tank includes two parts of low temperature water exchange heater 3 and high temperature evaporator 5; described low temperature section superconducting heat pipe 2 communicates with flue gas heat exchange box 1 and low temperature water exchange heater 3, The waste heat of the low-temperature flue gas in the flue gas heat exchange box 1 is introduced into the low-temperature water exchange heater 3; the high-temperature section superconducting heat pipe 4 is connected with the flue gas heat exchange box 1 and the high-temperature evaporator 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com