Method for manufacturing roll-to-roll colored electronic paper

A manufacturing method and technology of electronic paper, applied in the direction of instruments, identification devices, static indicators, etc., can solve problems such as product failure, deformation of electronic paper plastic substrate, reliability of electronic paper diaphragm, etc., to increase production capacity and improve production Speed and manufacturing cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

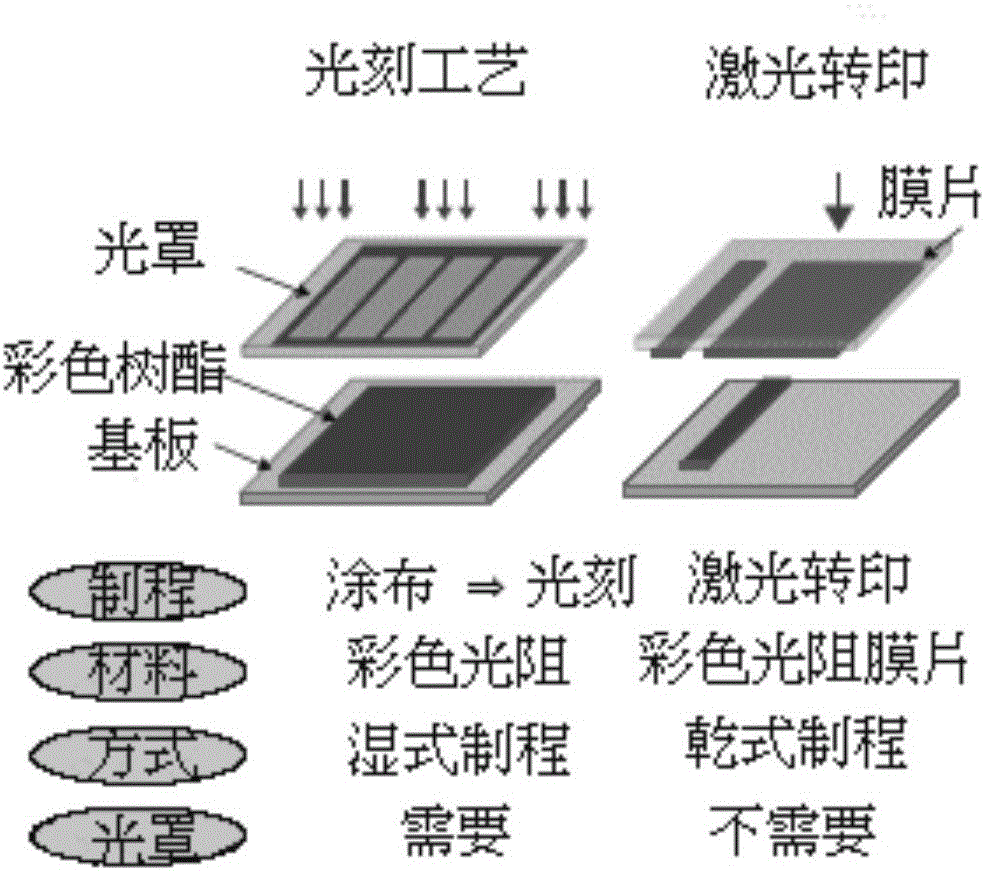

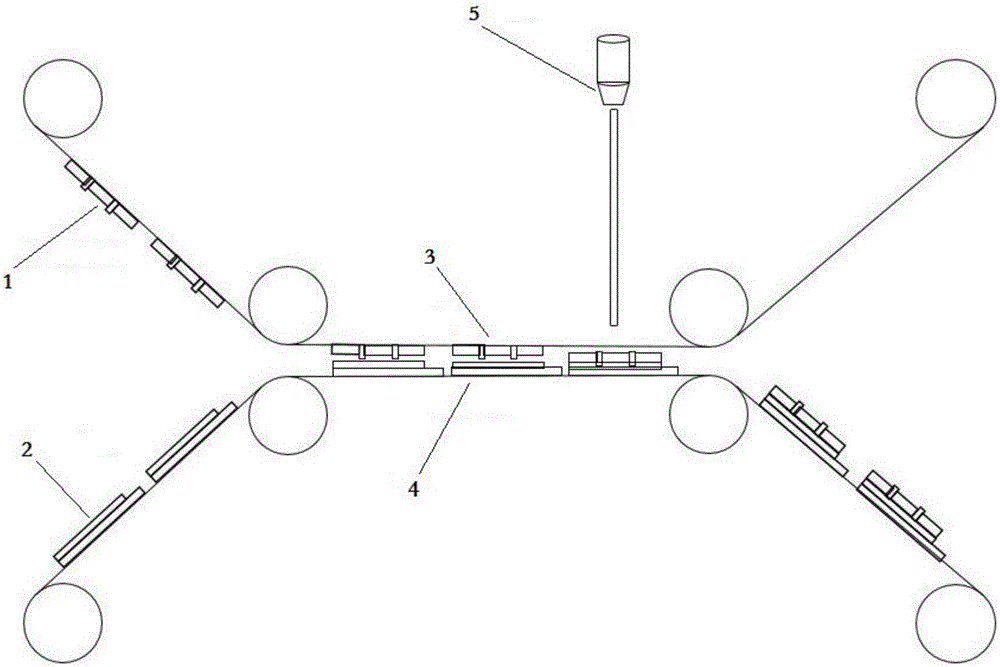

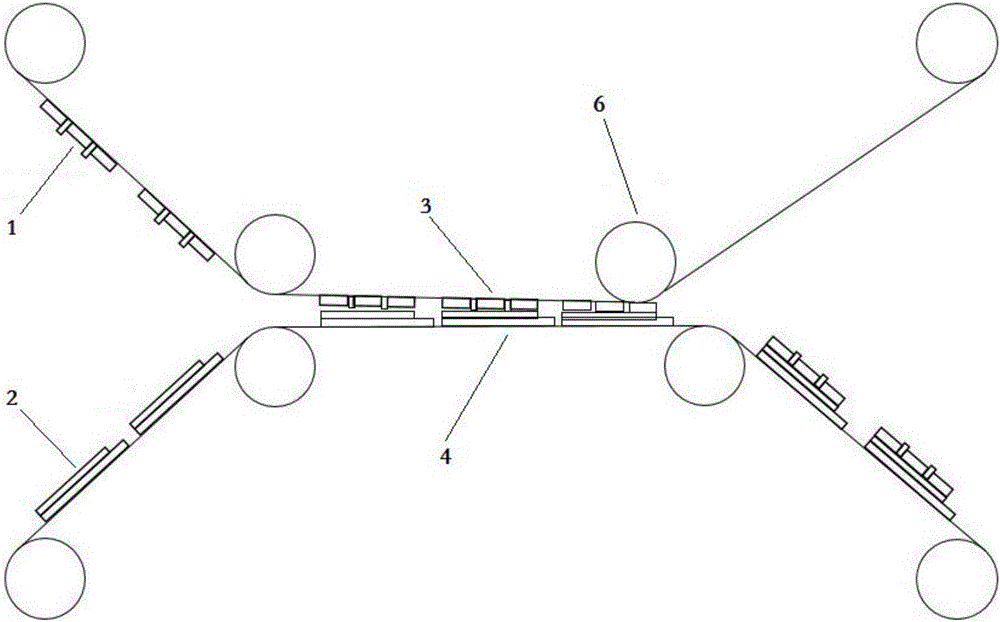

[0030] A roll-to-roll color electronic paper manufacturing method provided by the present invention comprises the following steps: 1. Fabricate a driving circuit, a segment code circuit or a thin film transistor circuit on the lower roll substrate (flexible glass), and press the electronic ink to form an electronic paper. Ink display module; 2. Make a color filter on the roll-up substrate (flexible glass); 3. Align the roll-up substrate and the roll-down substrate; use the energy of the laser beam to selectively convert red, green, blue The color pigment is laser transferred from the color filter ribbon of the upper roll substrate to the lower roll substrate to form the pixels of the color filter and complete the production of flexible color electronic paper.

Embodiment approach 2

[0032] A roll-to-roll color electronic paper manufacturing method provided by the present invention comprises the following steps: 1. Fabricate a driving circuit, a segment code circuit or a thin film transistor circuit on the lower roll substrate (plastic), and press the electronic ink to form the electronic ink Display module; 2. Make a color filter on the upper roll substrate (plastic); 3. Align the upper roll substrate and the lower roll substrate; use the energy of the laser beam to selectively mix red, green, and blue pigments The color filter ribbon of the upper roll substrate is laser transferred to the lower roll substrate to form the pixels of the color filter and complete the production of flexible color electronic paper.

Embodiment approach 3

[0034]A roll-to-roll color electronic paper manufacturing method provided by the present invention comprises the following steps: 1. Fabricate a driving circuit, a segment code circuit or a thin film transistor circuit on the lower roll substrate (metal sheet), and press the electronic ink to form an electronic paper. Ink display module; 2. Make color filters on the upper roll substrate (metal sheet); 3. Align the upper roll substrate and the lower roll substrate; The color pigment is laser transferred from the color filter ribbon of the upper roll substrate to the lower roll substrate to form the pixels of the color filter and complete the production of flexible color electronic paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com