Condenser heat source based thermoelectric power generation apparatus

A technology of thermoelectric power generation and thermoelectric power generation sheets, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems of heat energy waste and inability to recycle condensers, and achieve the effects of reducing space, improving power generation efficiency, and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

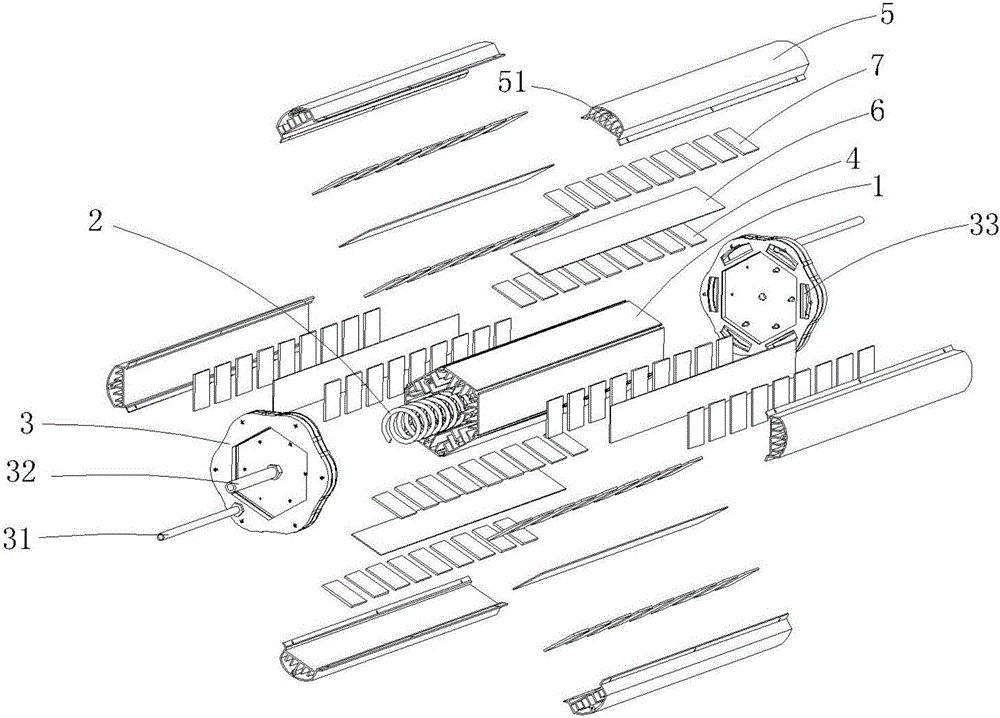

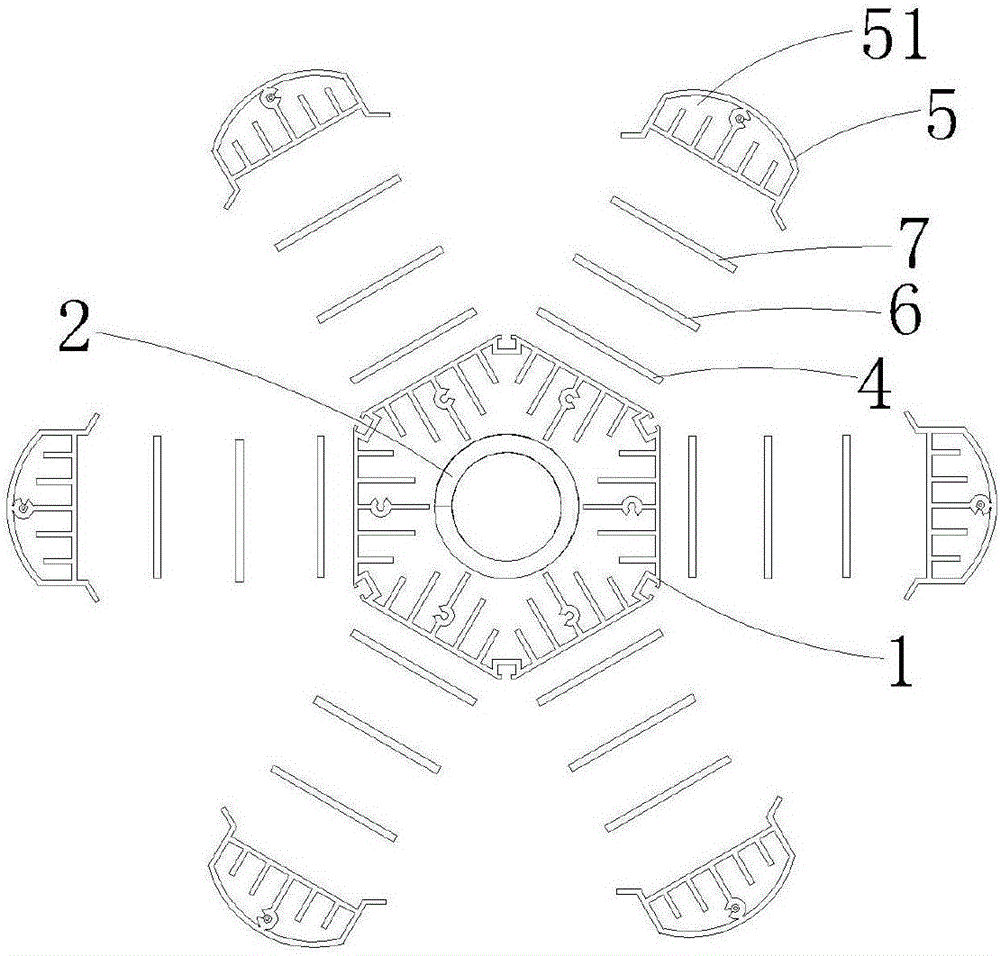

[0025] Such as figure 1 , figure 2 As shown, this embodiment is mainly composed of a casing 1, a condenser tube 2, a side cover 3, a first power generation chip 4, a heat dissipation water tank 5, a vapor chamber 6, and a second power generation chip 7. Wherein, the condenser is composed of a shell 1 and a condenser tube 2, forming a water-cooled condenser. Condenser tube 2 is a spiral shape, with a hollow tube structure that circulates the refrigerant inside. When the compressor is working, it compresses the steam evaporated by the evaporator to increase the surface temperature of the condenser tube 2. 2 for efficient use of heat, we place the condenser tube 2 in the inner cavity of the shell 1, fill the cavity with a heat-conducting liquid, such as water, oil, etc., and install two symmetrical sides with screws at both ends of the shell 1 Cover 3 for sealing. At the same time, the side cover 3 is provided with a hollow side tube 31 and a center tube 32, which run through...

Embodiment 2

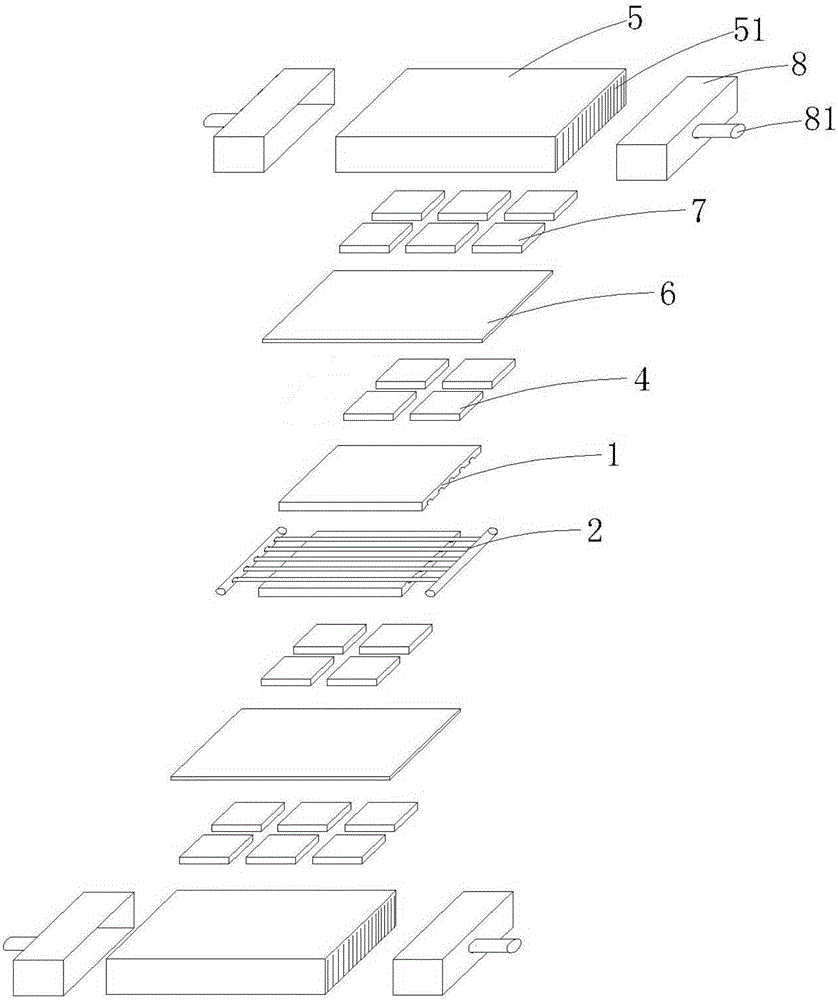

[0039] Such as image 3As shown, this embodiment is mainly composed of a housing 1, a condenser tube 2, a first power generation chip 4, a heat dissipation tank 5, a vapor chamber 6, a second power generation chip 7, an end cover 8, and the like. Among them, the condenser has a shell 1 and a condenser tube 2 to form a flat-plate condenser. The condensation pipe 2 is a series-parallel structure in the shape of a hollow tube to enlarge the contact area with the shell 1 . The shell 1 is divided into upper and lower parts, and is provided with a groove corresponding to the tubular size of the condenser 2. After being closed, the condenser tube 2 is in close contact with the shell 1. In order to improve the heat conduction efficiency, the condenser tube can be welded and / or bonded and solidified. 2 is installed in the housing 1.

[0040] On the upper and lower surfaces of the shell 1 are respectively installed thermoelectric power generation structures with the same structure, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com