Self-propelled corn grain direct harvesting and straw baling combine harvester

A combine harvester, self-propelled technology, applied in the direction of balers, harvesters, threshing equipment, etc., can solve the problems affecting the quality of spring sowing operations, heavy diseases and insect pests, and difficulty in sowing, so as to solve the shortage of rural labor and reduce physical strength. Labor, the effect of reducing the cost of harvesting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to clearly illustrate the technical solution of the present invention, the specific implementation manner of the present invention is described as follows in conjunction with the accompanying drawings:

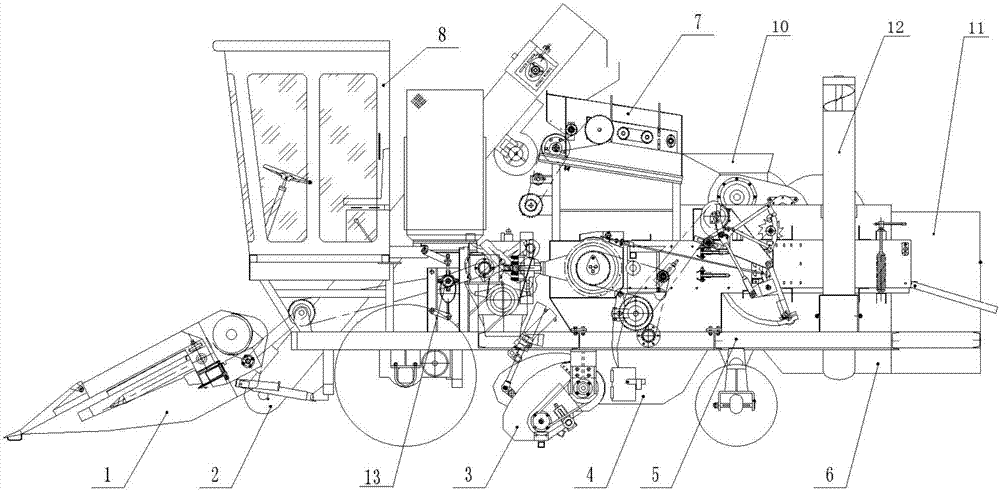

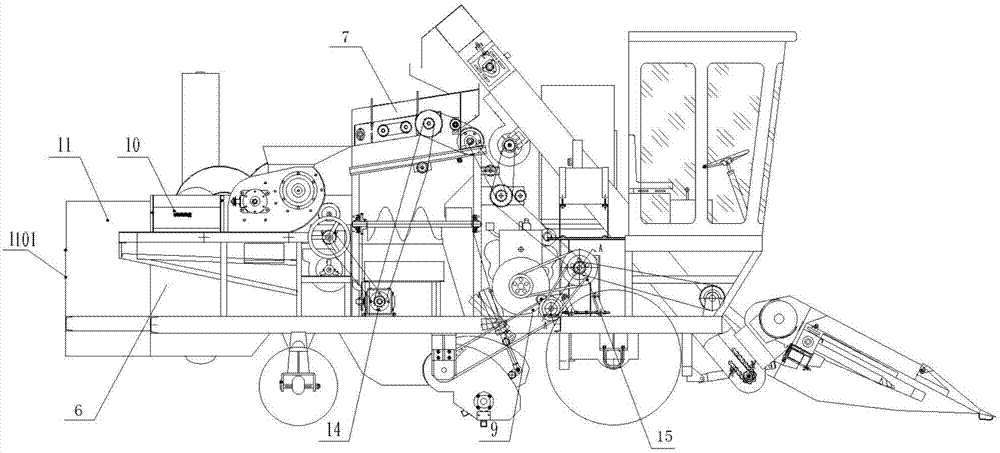

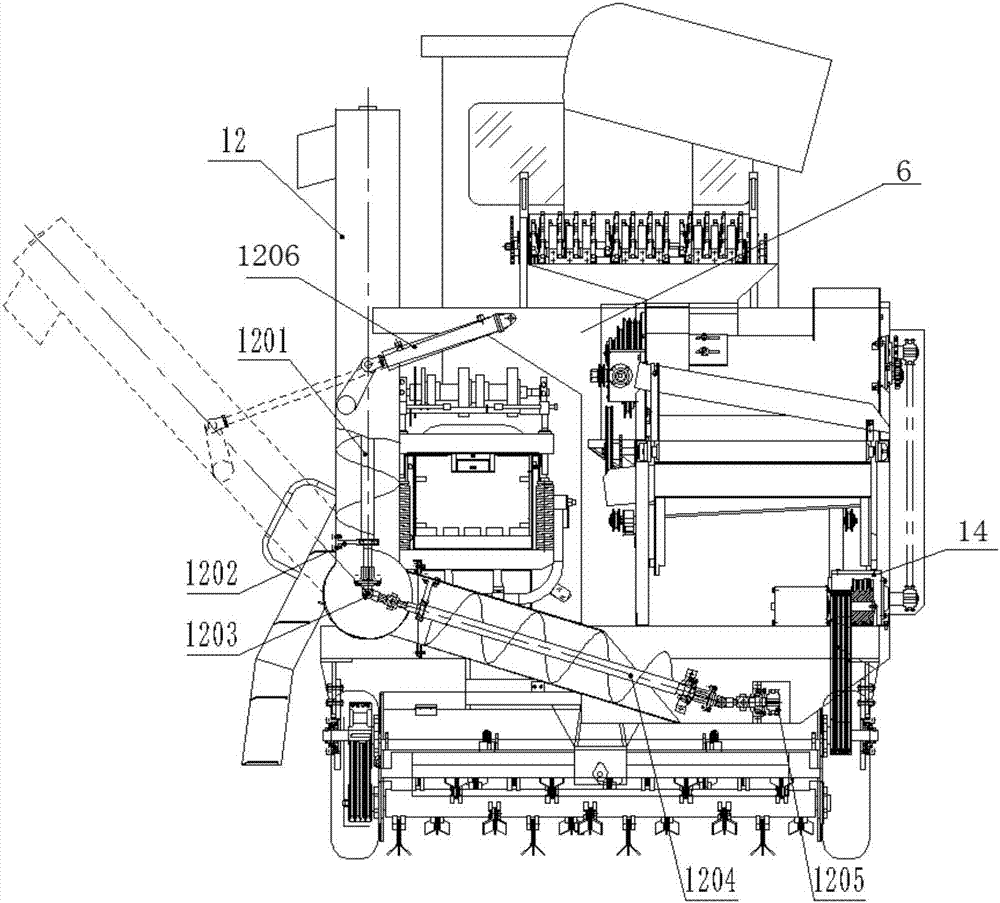

[0045] as attached figure 1 and figure 2 As shown, the present invention discloses a self-propelled corn grain direct harvesting and straw baling combine harvester, comprising: harvesting platform 1, ear elevator 2, straw collector 3, baling device 4, chassis 5, grain Grain tank 6, fruit ear peeling mechanism 7, driver's cab 8, engine 9, double-drum thresher 10, corn cob box 11, grain conveyor 12, first transmission gearbox 13 for transmitting power to the pressing device 4, The second transmission gearbox 14 used to transmit power to the double-drum thresher 10 and the grain conveyor 12 and the intermediate transmission shaft assembly 15 used to transmit power to the engine 9 and other components.

[0046] The self-propelled corn stalk harvesting and baling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com