Superstrong pressure resisting toy wheel mold

A technology for molds and toys, which is applied in the field of ultra-strong anti-compression toy wheel molds, can solve the problems of inability to achieve continuity and batch production, and achieve the effects of rapid continuity, accelerated progress, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

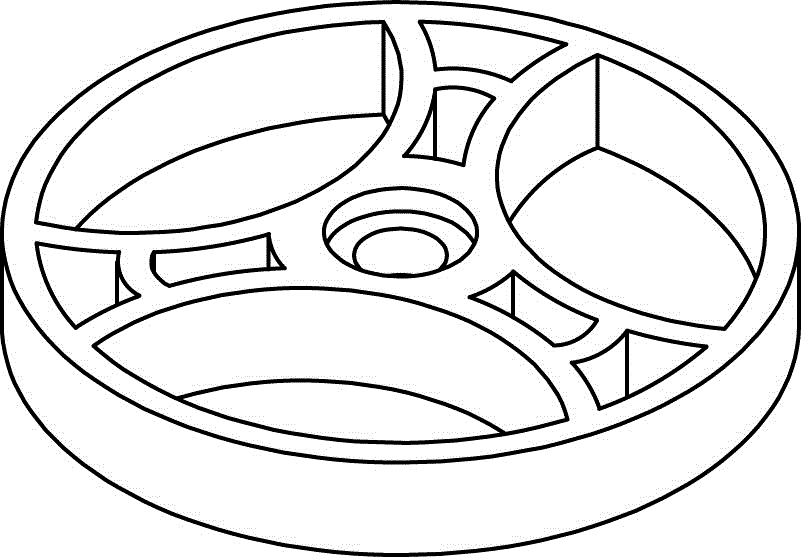

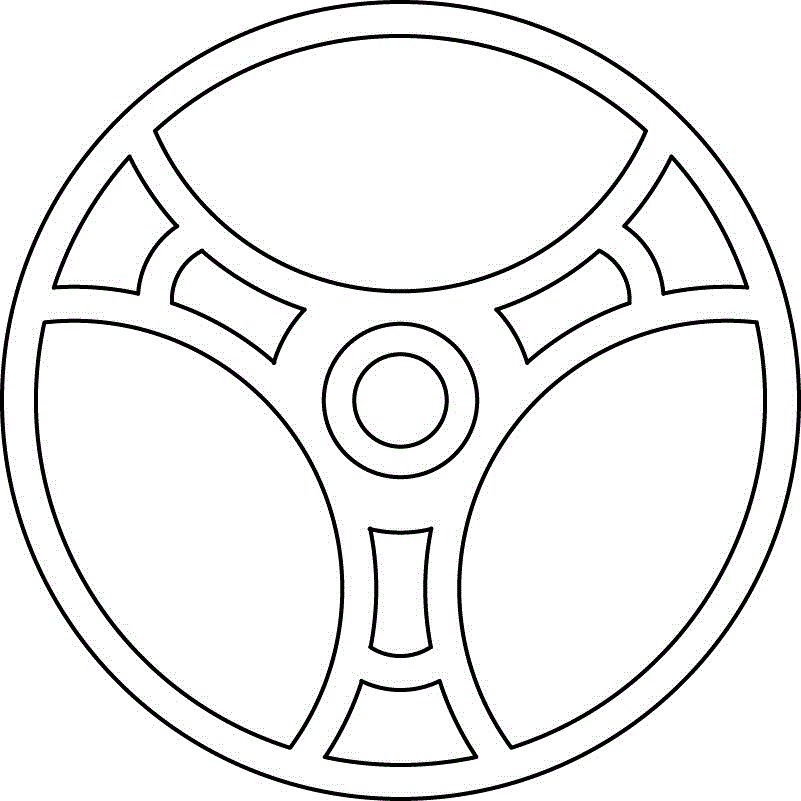

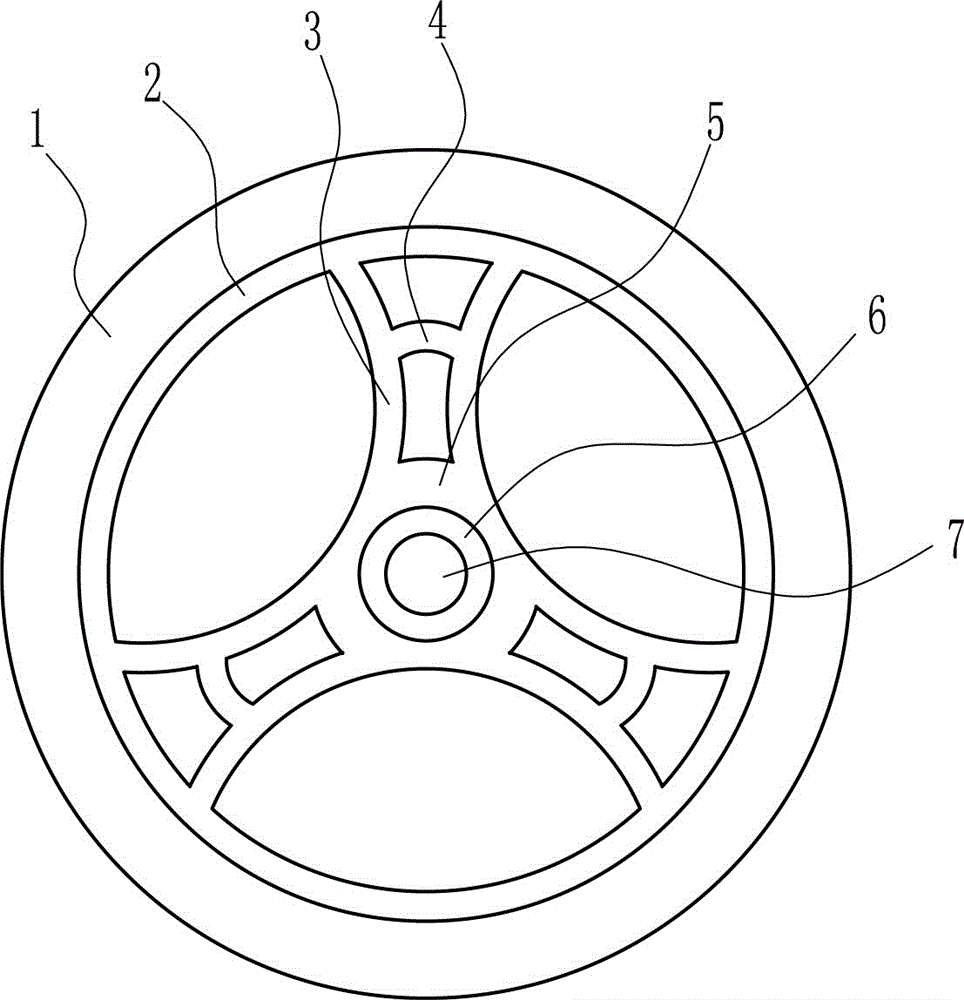

[0021] A super strong anti-compression toy wheel mold, such as Figure 1-6 As shown, it includes an upper mold body 1, a large cylindrical bump I6, a small cylindrical bump 7, a lower mold body 8, and a large cylindrical bump II9. The upper mold body 1 is provided with an annular groove 2 and three long arcs. Groove 3, three short arc grooves 4, circular groove 5, large cylindrical bump I6 and small cylindrical bump 7, annular groove 2 is set on the upper mold body 1, three long arc grooves 3 is located inside the annular groove 2, three long arc grooves 3 are in an annular array, and both ends of each long arc groove 3 are connected to the annular groove 2, and three short arc grooves 4 are located in the annular groove 2, three short arc-shaped grooves 4 ring arrays, the two ends of each short arc-shaped groove 4 are connected with the annular groove 2, the circular groove 5 is located in the middle of the annular groove 2, and the circular groove 5 is connected with three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com