A kind of brine purification device and method for removing strontium element from mirabilite brine

A brine purification and brine technology, applied in the direction of alkali metal halide purification, etc., can solve the problem of reducing the content of strontium element in liquid salts to 0.1ppm and below.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

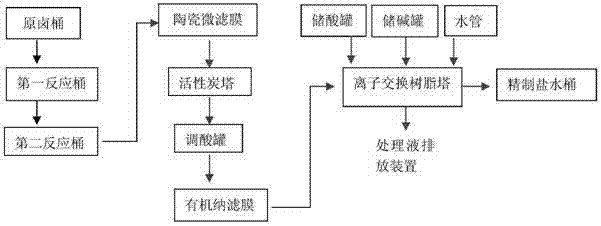

Image

Examples

Embodiment 1

[0017] Take the purified 1L Glauber's salt brine with a sodium chloride content of 305g / L, a sodium sulfate content of 12g / L, and a calcium sulfate content of 2.0g / L as an example. Reaction barrel, add calcium chloride 0.8g / L in the first reaction barrel, filter after stirring for 1 hour, send the clarified liquid into the second reaction barrel, add soda ash 1.1g / L in the second reaction barrel, add caustic soda 0.3g / L, titration method to determine the over-alkali content of soda ash is 0.25g / L, stirring and reacting for 2 hours, the solution or suspension after the reaction is directly sent to the membrane device, and the permeate is passed through acid adjustment and residual chlorine removal process After being sent to the nanofiltration process, the solution on the permeate side is treated with a chelating ion exchange resin device to obtain a refined brine clarified liquid, which is measured by an inductively coupled plasma spectrometer. index.

Embodiment 2

[0019] Take the purified 1L Glauber's salt brine with a content of 225g / L sodium chloride, 18g / L sodium sulfate and 1.5g / L calcium sulfate as an example. The original brine of Glauber's salt is sent to the first Reaction barrel, add calcium chloride 1.2g / L in the first reaction barrel, filter after stirring for 1 hour, send the clarified liquid into the second reaction barrel, add soda ash 1.45g / L in the second reaction barrel, add caustic soda 0.3g / L, the excess alkalinity of soda ash determined by titration method is 0.30g / L, stirred and reacted for 2 hours, the solution or suspension after the reaction is directly sent to the membrane device, and the permeate is passed through acid adjustment and residual chlorine removal process After being sent to the nanofiltration process, the solution on the permeate side is treated with a chelating ion exchange resin device to obtain a refined brine clarified liquid, which is measured by an inductively coupled plasma spectrometer. ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com