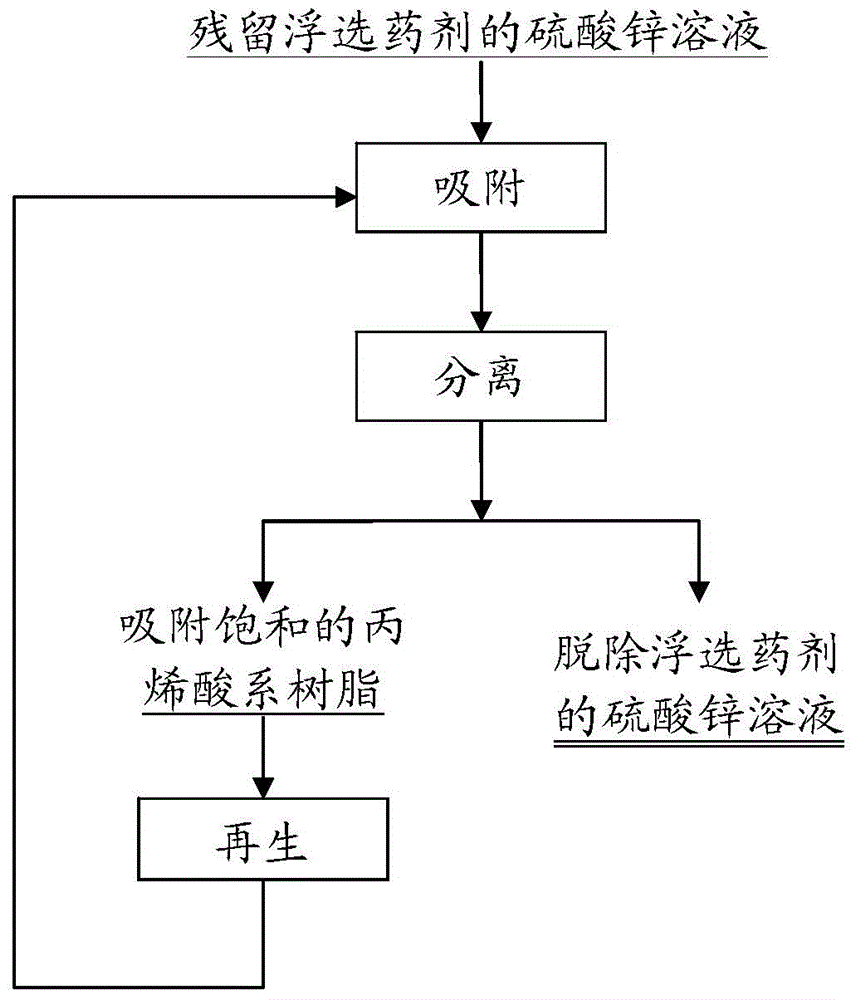

A method for removing residual flotation agents in zinc sulfate solution

A zinc sulfate solution and flotation reagent technology, applied in the field of hydrometallurgy, can solve the problems of large loss of zinc sulfate, large loss of metal, environmental pollution by flue gas, etc., and achieve high industrial feasibility, small adsorption loss, and short process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Zinc oxide concentrate is obtained by flotation of low-grade zinc oxide ore in a certain place in Yunnan, and the obtained concentrate is leached by conventional wet method to obtain zinc sulfate solution with residual flotation agent.

[0028] The main components of the zinc oxide concentrate are shown in Table 1. Table 1 is the main chemical components of the zinc oxide concentrate provided in Example 1 of the present invention; the content of the residual flotation agent in the zinc sulfate solution of the residual flotation agent is passed Measured by TOC instrument, its value is TOC=103.2mg / L, other main elements in the zinc sulfate solution of the residual flotation agent are shown in Table 2, and Table 2 is the sulfuric acid of the residual flotation agent provided in Example 1 of the present invention Analysis of major elements in zinc solutions.

[0029] Table 1 Main chemical components of zinc oxide concentrate provided in Example 1 of the present invention

...

Embodiment 2

[0034] 1 L of the residual flotation agent zinc sulfate solution prepared in Example 1 was mixed with 6g of 110 resin, adsorbed at 25° C. for 2 hours, filtered and separated to obtain a zinc sulfate solution with the flotation agent removed.

[0035] The removal rate of the residual flotation agent is shown in Table 3, and Table 3 is the removal rate of the residual flotation agent at different temperatures provided by the Examples and Comparative Examples of the present invention.

Embodiment 3

[0037]1 L of the zinc sulfate solution with residual flotation agent prepared in Example 1 was mixed with 6g of 116 resin, adsorbed at 25°C for 2 hours, filtered and separated to obtain a zinc sulfate solution with the flotation agent removed.

[0038] Measured by a TOC meter, the TOC value of the residual flotation reagent in the zinc sulfate solution was 2.016 mg / L; the removal rate of the residual flotation reagent is shown in Table 3, which is provided by the examples and comparative examples of the present invention. Removal rates of residual flotation reagents at different temperatures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com