Preparation method of amino aminoacetaldehyde dimethyl acetal

A technology of aminoacetaldehyde dimethyl acetal and chloroacetaldehyde dimethyl acetal, which is applied in the field of medicine and chemical industry, can solve the problems of high cost, complex process, difficult promotion and industrialization, etc., and achieve the effect of improving recovery rate and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

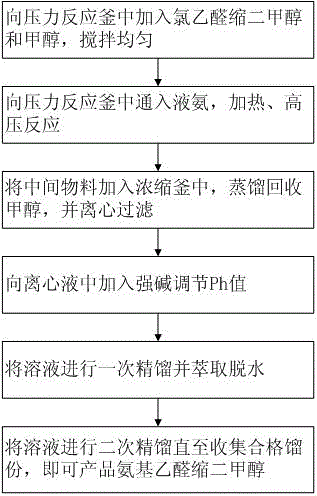

Image

Examples

Embodiment 1

[0020] Add chloroacetaldehyde dimethyl acetal and methanol into the pressure reaction kettle, stir evenly; then add liquid ammonia, heat to 150°C and carry out high-pressure reaction; put the intermediate material into the concentration kettle, and carry out multiple distillations, the pressure of each distillation From high to low until methanol is successfully recovered, and the solution is centrifugally filtered; the concentration of 50% sodium hydroxide is added to the centrifuge to adjust the pH value to 12; rectification, extraction and dehydration are carried out under normal pressure And carry out secondary rectification again after purification, control secondary rectification as vacuum rectification to guarantee safety until collecting qualified cuts, obtain product product aminoacetaldehyde dimethyl acetal.

Embodiment 2

[0022] Add chloroacetaldehyde dimethyl acetal and methanol into the pressure reaction kettle, stir evenly; then add liquid ammonia, heat to 150°C and carry out high-pressure reaction; put the intermediate material into the concentration kettle, and carry out multiple distillations, the pressure of each distillation From high to low until methanol is successfully recovered, and the solution is centrifugally filtered; adding 70% sodium hydroxide to the centrifuged liquid to adjust the pH value to 14; performing rectification, extraction and dehydration under normal pressure And carry out secondary rectification again after purification, control secondary rectification as vacuum rectification to guarantee safety until collecting qualified cuts, obtain product product aminoacetaldehyde dimethyl acetal.

Embodiment 3

[0024] Add chloroacetaldehyde dimethyl acetal and methanol into the pressure reaction kettle, stir evenly; then add liquid ammonia, heat to 150°C and carry out high-pressure reaction; put the intermediate material into the concentration kettle, and carry out multiple distillations, the pressure of each distillation From high to low until methanol is successfully recovered, and the solution is centrifugally filtered; the concentration of 55% sodium hydroxide is added to the centrifuge to adjust the pH value to 13; rectification, extraction and dehydration are carried out under normal pressure And carry out secondary rectification again after purification, control secondary rectification as vacuum rectification to guarantee safety until collecting qualified cuts, obtain product product aminoacetaldehyde dimethyl acetal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com