Hot water quenching device and method for direct-reduced iron (DRI) of rotary hearth furnace

A technology of reduced iron and rotary hearth furnace, applied in the direction of fluidized bed furnace, etc., can solve the problems of equipment stuck, easy to accumulate at the bottom of the tank, increase resistance, etc., and achieve the effect of convenient maintenance and replacement and high operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

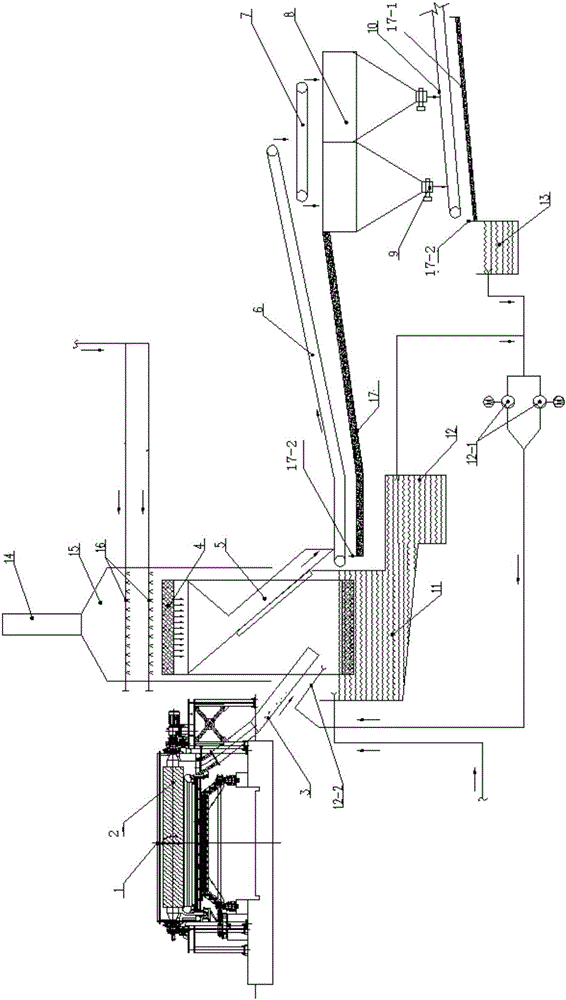

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the present invention discloses a rotary hearth furnace direct reduction iron hot water quenching device, comprising a rotary hearth furnace 1, a rotary hearth furnace discharge mechanism 2, a hot water pool 11, a sedimentation pool 12 connected to the hot water pool 11, and a The horizontal cylindrical centrifugal dehydrator 4 on 11, the hot DRI chute 3 extending from the rotary hearth furnace 1 into the cylinder cavity of the horizontal cylindrical centrifugal dehydrator 4, the material trough 5 also located in the cylinder cavity, the material trough 5, the first conveying device 6 below the output end (in this embodiment, a belt conveyor 6), the storage bin 8 located below the output end of the first conveying device 6, the second conveying device located below the outlet of the storage bin 8 Device 10 (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com