Basement concrete outer wall flexible waterproof wall bushing structure and construction method

A flexible waterproof and wall-piercing casing technology, which is applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of large water leakage hazards of bolts, long flexible waterproof casings, increased material costs, etc., to reduce difficulty and workload, beautiful appearance, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, the preparation process requirements for the flexible waterproof casing, the construction technical requirements for wall steel bar binding, the construction process requirements for wall concrete pouring, and the steel bar welding process requirements will not be described in detail, and the basement concrete outer wall involved in the present invention will be focused on The construction mode of the micro-embedded flexible waterproof casing through the wall.

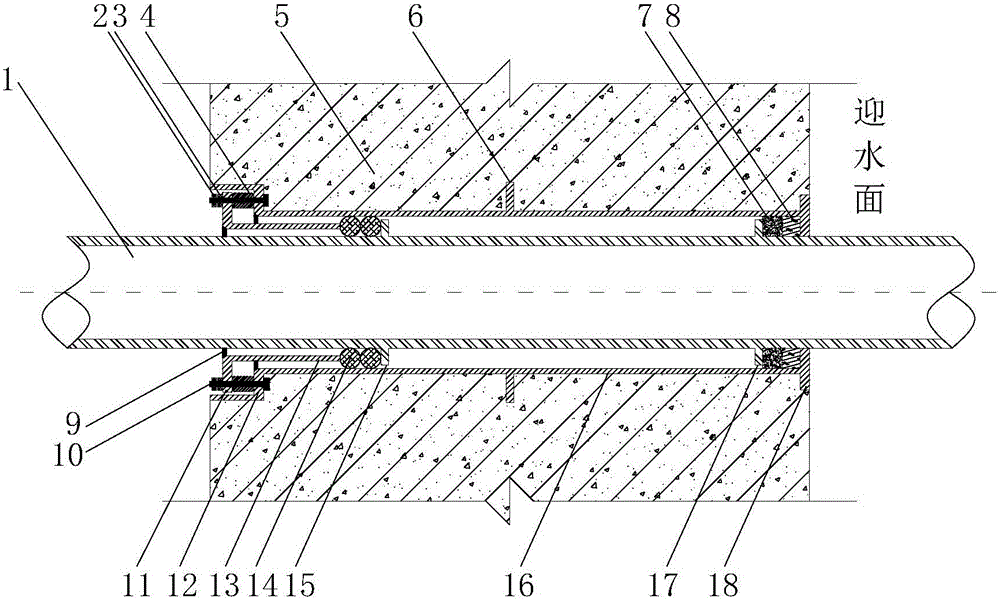

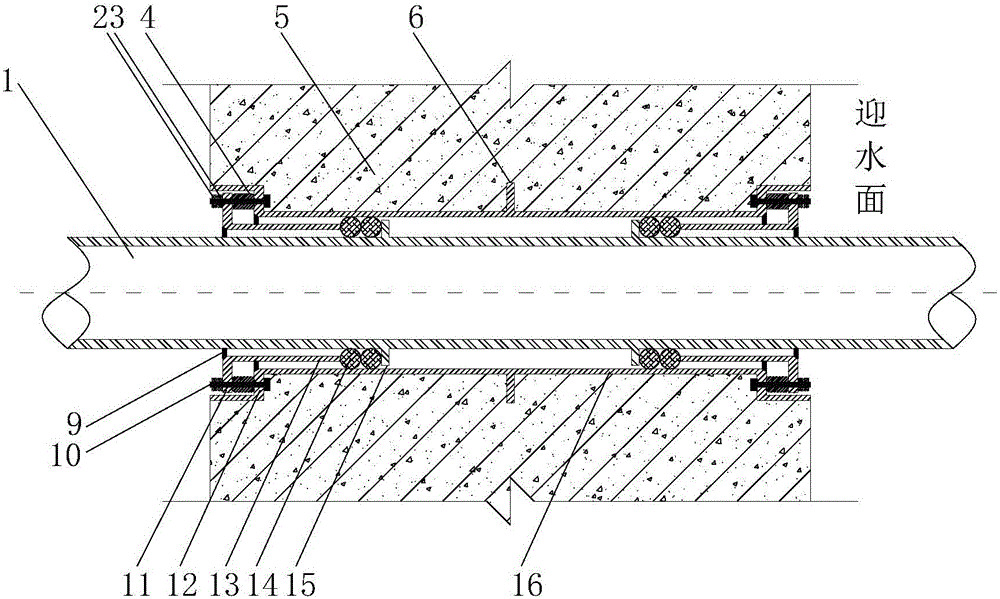

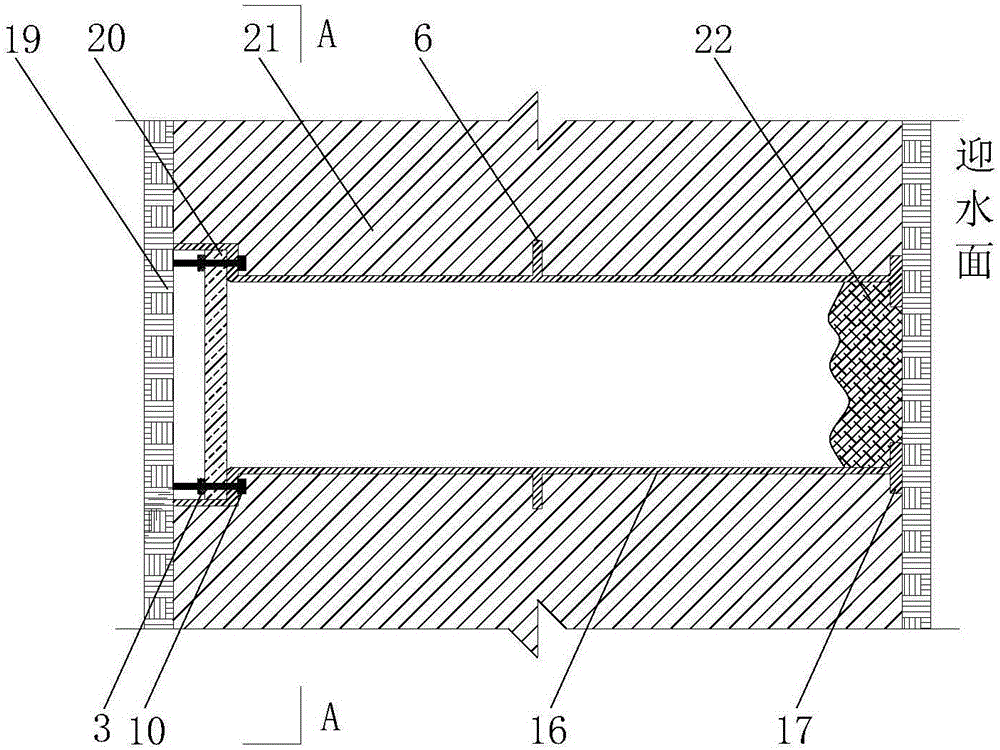

[0037] figure 1 It is a cross-sectional view of the structure of the micro-embedded flexible waterproof wall-through casing on the concrete exterior wall of the basement. figure 2 It is a cross-sectional view of the structure of the flexible waterproof wall-piercing casing when the working space on the upstream surface is sufficient. image 3 yes figure 1 The schematic diagram of the support form of the structure shown, Figure 4 yes figure 2 The schematic diagram of the support form of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com