Thermal management system for new energy vehicle power battery

A heat management system and power battery technology, which is applied to power devices, secondary batteries, battery temperature control, etc., can solve the problem that cold wind can only blow to one side of the power battery of new energy vehicles, the cooling effect is not good, and new energy vehicles Power battery can not work and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings:

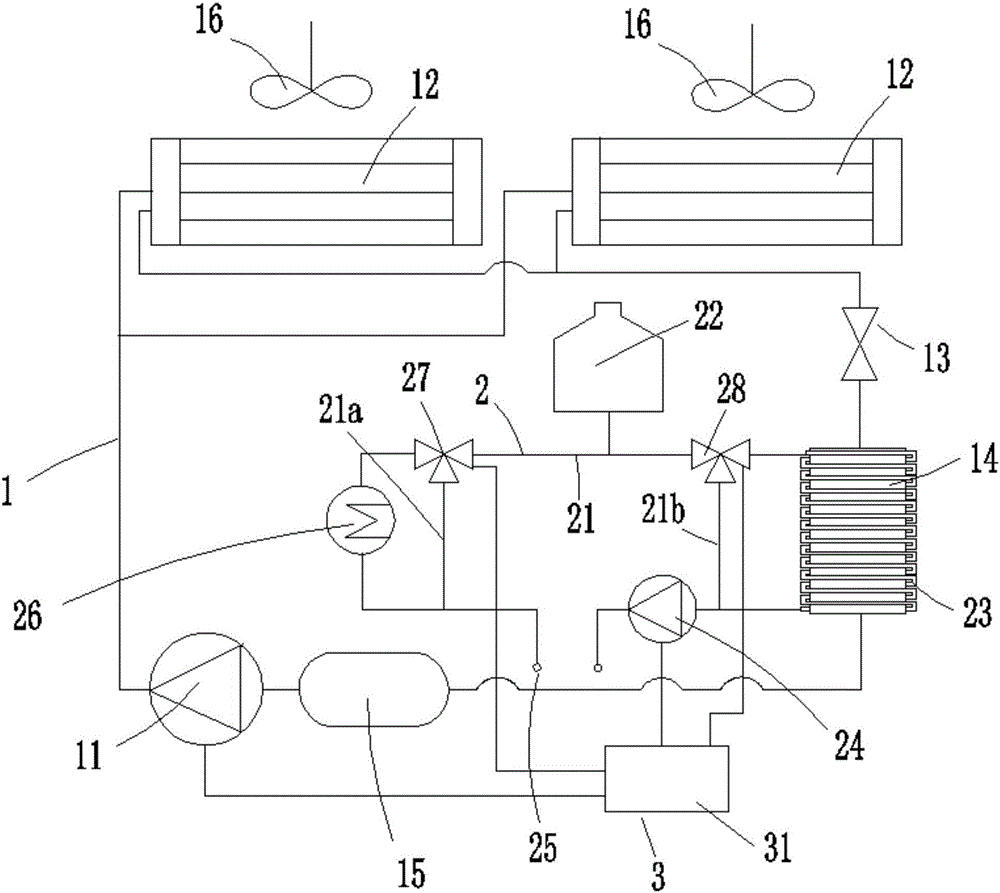

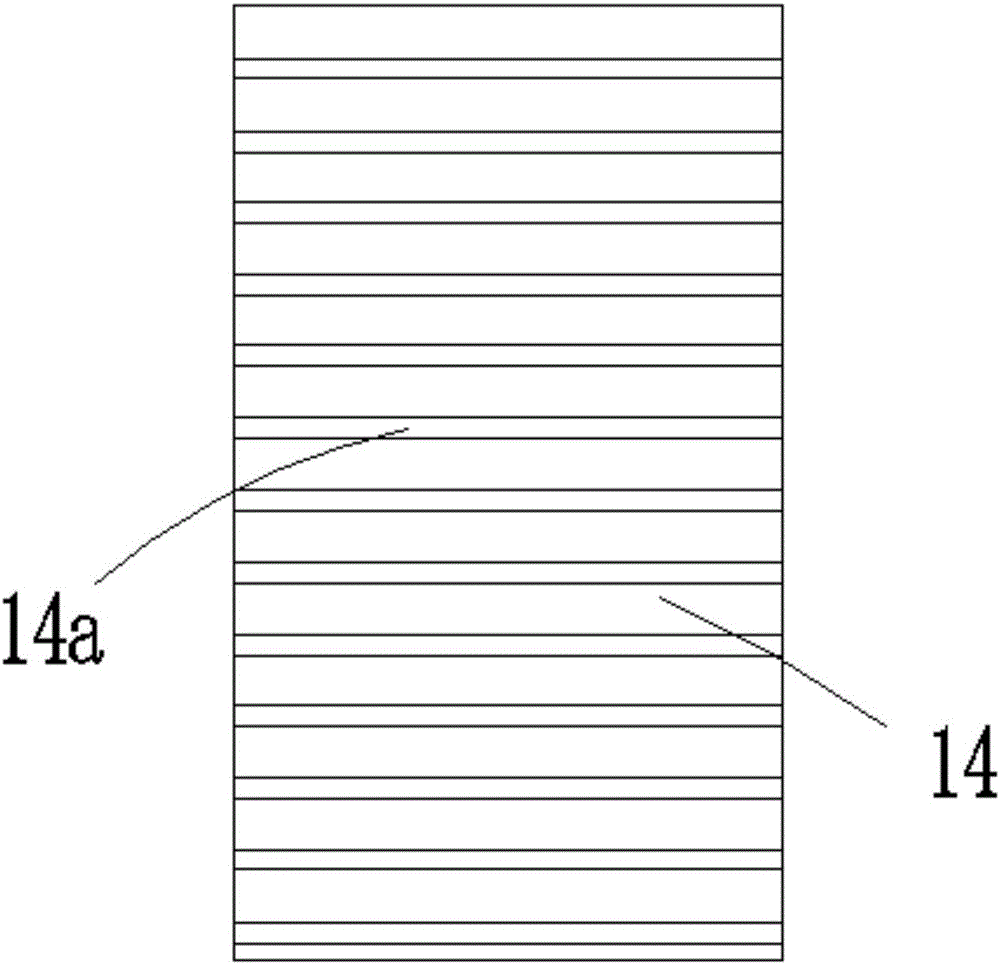

[0021] The thermal management system for the power battery of a new energy vehicle of the present invention includes a refrigerant circulation circuit 1 and a cooling liquid circulation circuit 2. The refrigerant circulation circuit 1 includes a compressor 11, a condenser 12, and a condenser connected in sequence through pipelines. The flow valve 13, the evaporator 14, and the gas-liquid separator 15. The gas-liquid separator 15 is connected back to the compressor 11. There is a refrigerant circulating in the refrigerant circuit 1, and the compressor 11 compresses the refrigerant into high temperature and high pressure gas. The condenser 12 Heat exchange with the external cold source to cool the high-temperature and high-pressure gas into low-temperature and high-pressure liquid, the throttle valve 13 reduces the pressure of the low-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com