Multi-surface cylinder type hybrid excitation switch magnetic flux linear motor

A hybrid excitation and switching magnetic flux technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of high motor cost, low motor efficiency, low thrust density, etc., and achieve better working performance, convenient processing and assembly. , the effect of reducing the amount of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

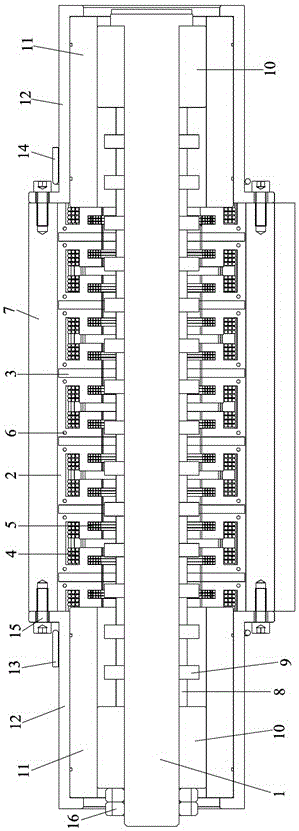

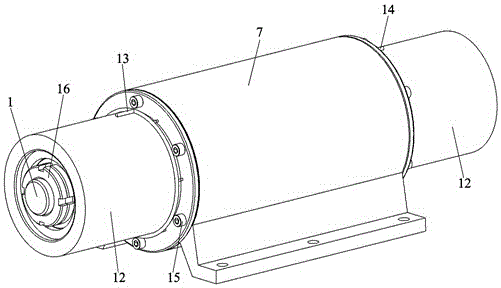

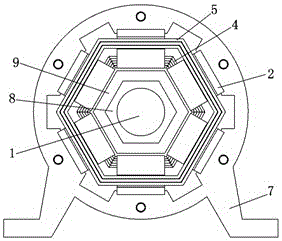

[0028] The following is a detailed introduction to the composition and structure of a multi-faced cylindrical hybrid excitation switch flux linear motor of the present invention in conjunction with the accompanying drawings:

[0029] refer to figure 1 , image 3 and Figure 6 As shown, the present invention is a multi-faced cylindrical hybrid excitation switch magnetic flux linear motor, refer to figure 1 As shown in the present invention, a multi-surface cylindrical hybrid excitation switch magnetic flux linear motor at least includes a mover mandrel 1, a stator core module 2, an armature winding 4, an excitation winding 5, a motor frame 7, and a mover pinion ring 8. The mover large gear ring 9, the secondary sliding sleeve 10, and the linear bearing 11. The mover mandrel 1 is arranged axially on the axis of the motor frame 7. The mover small gear ring 8 and the mover large Gear rings 9 are sequentially nested on the outer surface of the mover mandrel 1 at intervals along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com