A method for cracking polysiloxane oligomers containing long-chain fluoroalkyl groups

A chain fluoroalkyl and polysiloxane technology, which is applied in the field of polysiloxane oligomer cracking devices, can solve the problems of long duration of rectification process, reduced product yield, high boiling point of cyclic compounds, etc., and achieves improvement Effect of mass transfer and heat transfer, improvement of production efficiency, effect of shortening the rectification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

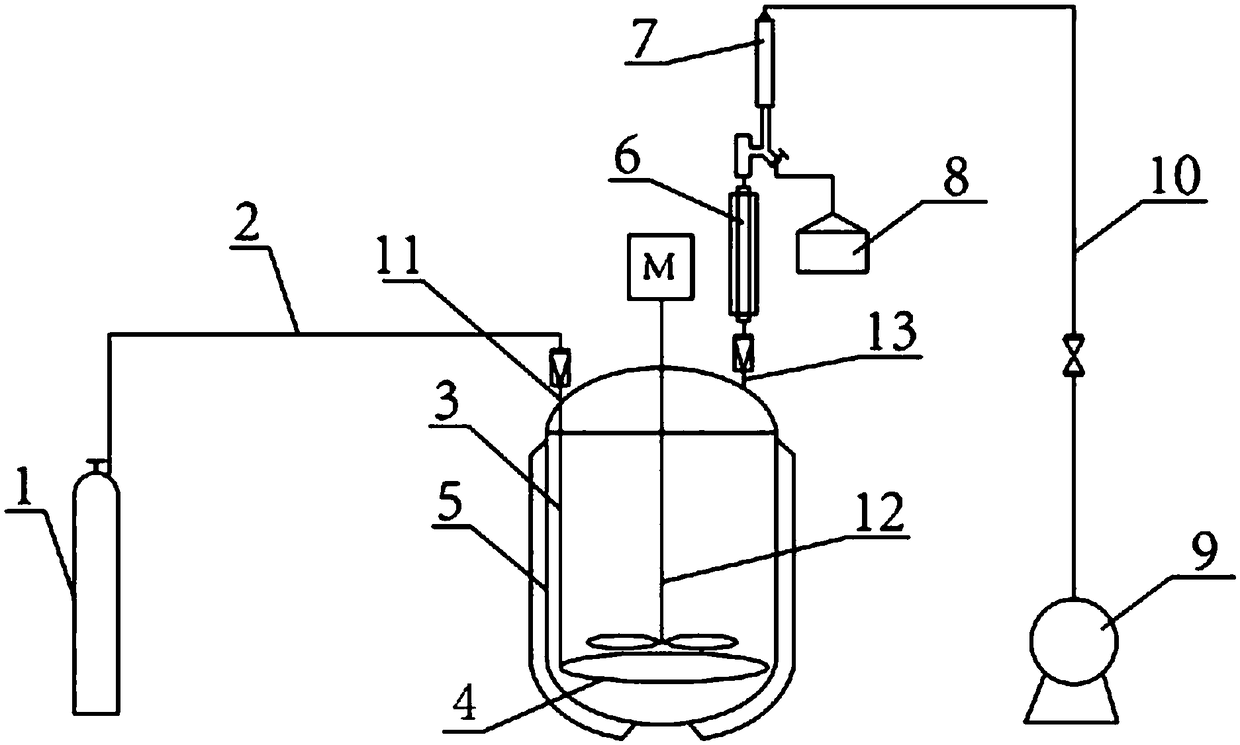

Image

Examples

Embodiment 1

[0044] 1) put R F for CF 3 CF 2 CF 2 CF 2 CH 2 CH 2 1000 mass parts of polysiloxane oligomers containing long-chain fluoroalkyl groups, 5 mass parts of potassium hydroxide, and 20 mass parts of stearyl alcohol are added in the cracking container, and the stirring is started, and vacuumization is started simultaneously, and the cracking container is gradually raised. Internal material temperature, before distilling out the distillate;

[0045] 2) After the former fraction is separated, start to continuously feed inert gas into the cracking vessel while keeping the vacuum in the cracking vessel at -0.95MPa, and continue to gradually increase the temperature of the material in the cracking vessel to extract cracked products until there is no product to continue mining out. The rectification time (the rectification time in the present invention refers to the time elapsed from the beginning of the separation of the front fraction to the end when no product continues to be ex...

Embodiment 2

[0047] 1) put R F for CF 3 CF 2 CF 2 CF 2 CH 2 CH 2 1000 mass parts of polysiloxane oligomers containing long-chain fluoroalkyl groups, 0.5 mass parts of potassium hydroxide, and 15 mass parts of stearyl alcohol are added in the cracking container, and the stirring is started, and vacuumization is started simultaneously, and the cracking container is gradually raised. Internal material temperature, before distilling out the distillate;

[0048] 2) After separating the previous fraction, start to continuously feed inert gas into the cracking vessel, keep the vacuum in the cracking vessel at -0.97MPa, and continue to gradually increase the temperature of the material in the cracking vessel to extract cracked products until there is no product to continue mining out. The rectification time was 3.5 hours, and a total of 926 g of cyclization cracking products were obtained.

Embodiment 3

[0050] 1) put R F for CF 3 CF 2 CF 2 CF 2 CH 2 CH 2 1000 mass parts of polysiloxane oligomers containing long-chain fluoroalkyl groups, 10 mass parts of potassium hydroxide, and 35 mass parts of stearyl alcohol are added in the cracking container, and the stirring is started, and vacuumizing is started simultaneously, and the cracking container is gradually raised. Internal material temperature, before distilling out the distillate;

[0051] 2) After the former fraction is separated, start to continuously feed inert gas into the cracking vessel while keeping the vacuum in the cracking vessel at -0.93MPa, and continue to gradually increase the temperature of the material in the cracking vessel to extract cracked products until there is no product to continue mining out. The rectification time was 4.0 h, and a total of 914 g of cyclization cracking products were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com