Arc-welding material additive manufacturing method for stainless steel part

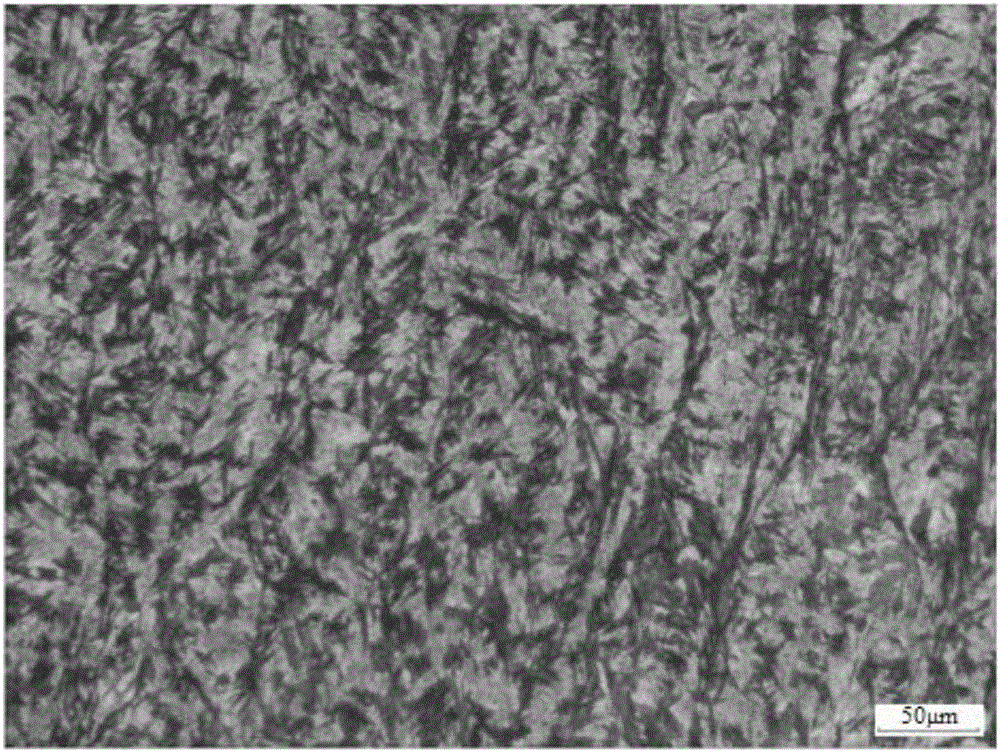

A technology of additive manufacturing and stainless steel, which is applied in the field of additive manufacturing, can solve problems affecting the performance of parts, temperature rise, etc., and achieve the effect of overcoming coarse and uneven grains and fine structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Taking the 308 stainless steel part whose forming size is 80mm×40mm×30mm as an example, the method of the present invention is described in detail:

[0029] (1) According to the structure of 308 stainless steel parts, establish a three-dimensional model of the part, use the subdivision software to perform layer processing on the three-dimensional model, convert the three-dimensional data of the part into two-dimensional data, according to the arc starting position and arc extinguishing between layers Based on the principle of position staggering, the scanning path planning is carried out for each layer of the part to obtain the information of the part layer.

[0030] (2) Choose 308 stainless steel wire as the forming material, the wire diameter is Φ1.2mm, choose ordinary stainless steel as the base material, set the arc welding current to 105A, arc welding voltage to 17V, wire feeding speed to 6.5m / min, shielding gas The flow rate is 15L / min, the scanning speed is 0.5m / ...

Embodiment 2

[0035] It is 20mm with forming diameter, and the 304 stainless steel cylinder part of height is 40mm is example the method of the present invention is described in detail:

[0036] (1) According to the structure of the 304 stainless steel cylinder part, a three-dimensional model of the part is established, and the three-dimensional model is layered by using the subdivision software, and the three-dimensional data of the part is converted into two-dimensional data. The principle of staggering the arc extinguishing position, planning the scanning path for each layer of the part, and obtaining the information of each layer of the part;

[0037] (2) Choose 304 stainless steel wire as the forming material, the wire diameter is Φ1.5mm, choose ordinary stainless steel as the base material, set the arc welding current to 90A, the arc welding voltage to 18V, the wire feeding speed to 4m / min, and the shielding gas flow 20L / min, scanning speed 0.3m / min, protective gas 97.5% Ar and 2.5% C...

Embodiment 3

[0042] Taking the 316 stainless steel part whose forming size is 40mm×40mm×40mm as an example, the method of the present invention is described in detail:

[0043] (1) According to the structure of 316 stainless steel parts, a three-dimensional model of the part is established, and the three-dimensional model is layered by using the subdivision software, and the three-dimensional data of the part is converted into two-dimensional data, according to the arc starting position and arc extinguishing between layers Based on the principle of position staggering, scan path planning is performed on each layer of the part to obtain part layer information;

[0044] (2) Choose 316 stainless steel wire as the forming material, the wire diameter is Φ1.2mm, choose ordinary stainless steel as the base material, set the arc welding current to 120A, the arc welding voltage to 13V, the wire feeding speed to 8m / min, and the shielding gas flow 25L / min, scanning speed 0.7m / min, protective gas 97.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com