Far-infrared polyolefin elastomer material, and preparation method and application thereof

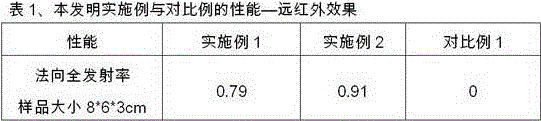

A polyolefin elastomer, far-infrared technology, used in applications, home appliances, spring mattresses, etc., can solve the problem of not having far-infrared, and achieve the effect of simplifying the process, easy to operate, and increasing far-infrared performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

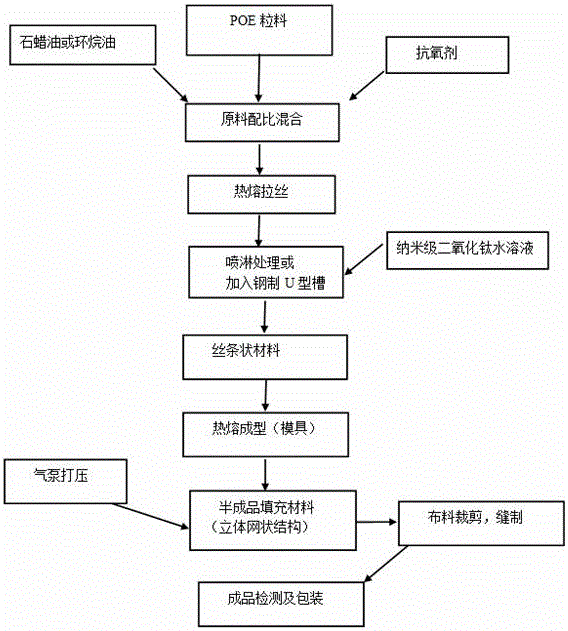

Method used

Image

Examples

Embodiment 1

[0035] a. Put 8g of nano-titanium dioxide into a beaker, add 0.4L of distilled water, and mix well to obtain a nano-titanium dioxide solution.

[0036] B, the nano titanium dioxide solution in the step a is packed in the watering can;

[0037] c, get 86g polyolefin elastomer, 10g paraffin oil, 1g tetrakis [beta-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, mix well, obtain mixed material;

[0038] d, the mixed material in step c is drawn at a temperature of 180~220°C to obtain a filamentous or strip semi-finished product, while maintaining the temperature of a filamentous or strip semi-finished product at 110°C, the nano-titanium dioxide obtained in step b The aqueous solution is evenly sprayed on the surface of the filament or strip semi-finished product to obtain the filament polyolefin elastomer composite material;

[0039] Add the above-mentioned polyolefin elastomer composite material into the mold, and use a hot-press molding machine for hot-pr...

Embodiment 2

[0041] a. Put 12g of nano-titanium dioxide into a beaker, add 0.5L of distilled water, and mix well to obtain a nano-titanium dioxide solution.

[0042] B, the nano titanium dioxide solution in the step a is packed in the steel U-shaped tube;

[0043] c, get 89g polyolefin elastomer, 12g naphthenic oil, 2g tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, mix well, obtain mixed material;

[0044] d, the mixed material in the step c is drawn at a temperature of 200° C. to obtain a strip-shaped semi-finished product. At the same time, maintain a strip-shaped semi-finished product temperature of 80° C. and pass through a steel U-shaped pipe or a steel U-shaped groove mold at a uniform speed. , that is, to obtain a filamentous polyolefin elastomer composite material;

[0045] Add the above-mentioned polyolefin elastomer composite material into the mold, and use a hot-press molding machine for hot-press molding. During the molding process, coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com