Comprehensive supporting structure of deep side slope of complex steep cliff and construction method

A technology for supporting structures and cliff walls, which is applied in foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as slope support erosion, poor stability at faults, and difficulty in ensuring stability, and achieve enhanced structural stability , shorten the construction time and improve the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In this embodiment, the technical requirements for the prestressed tensioning of anchor rods and anchor cables, the technical requirements for drilling on the cliff face, the construction technical requirements for concrete spraying, and the welding process requirements will not be repeated, and the complex and steep cliffs involved in the present invention will be emphasized. Implementation method of comprehensive support structure construction for deep slopes.

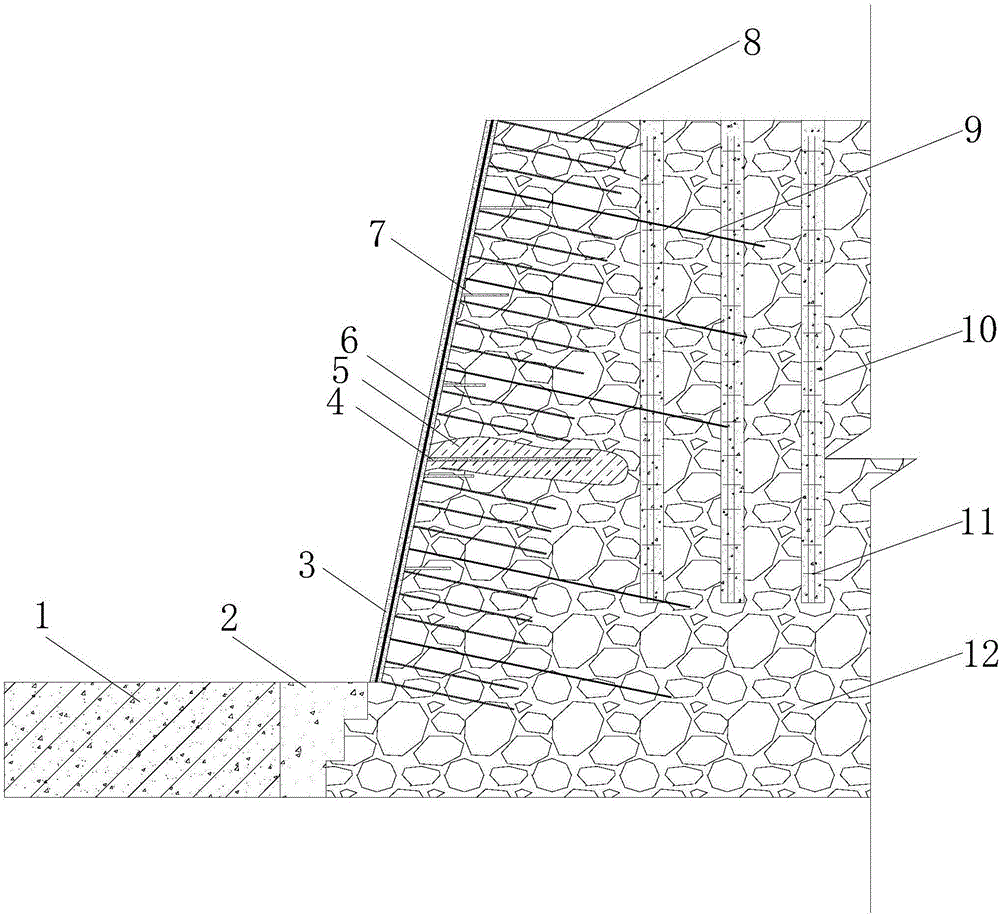

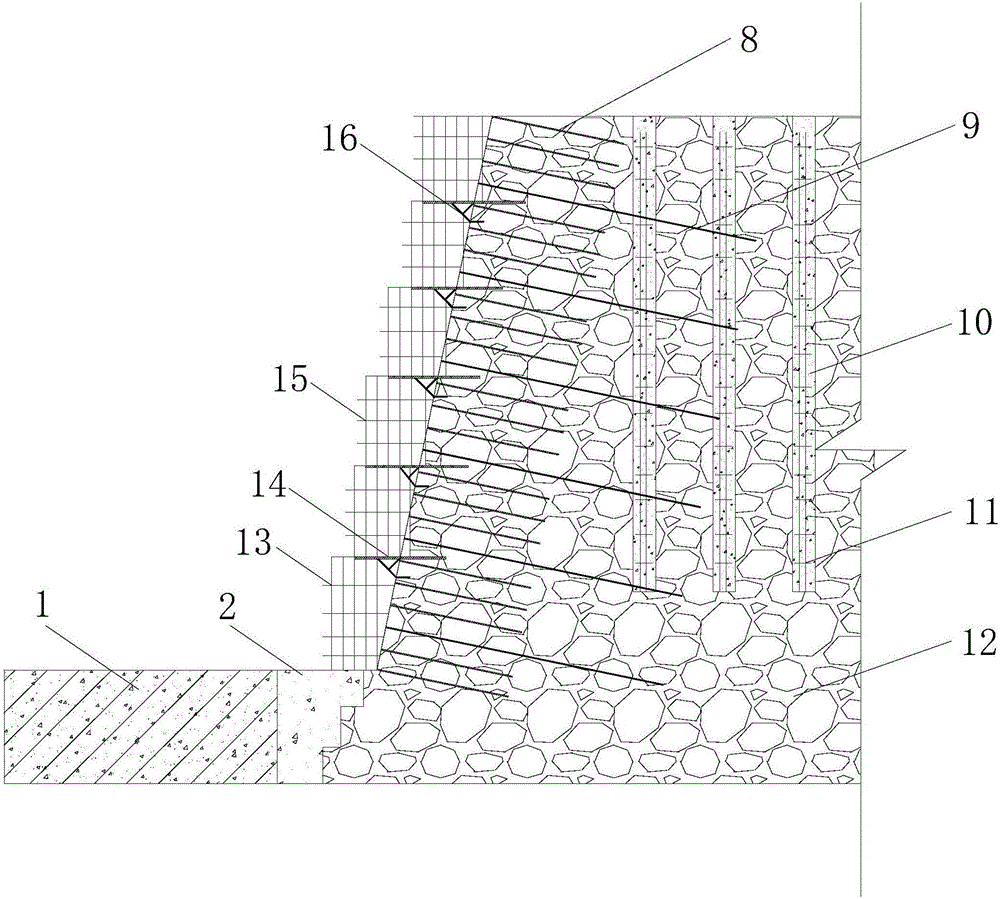

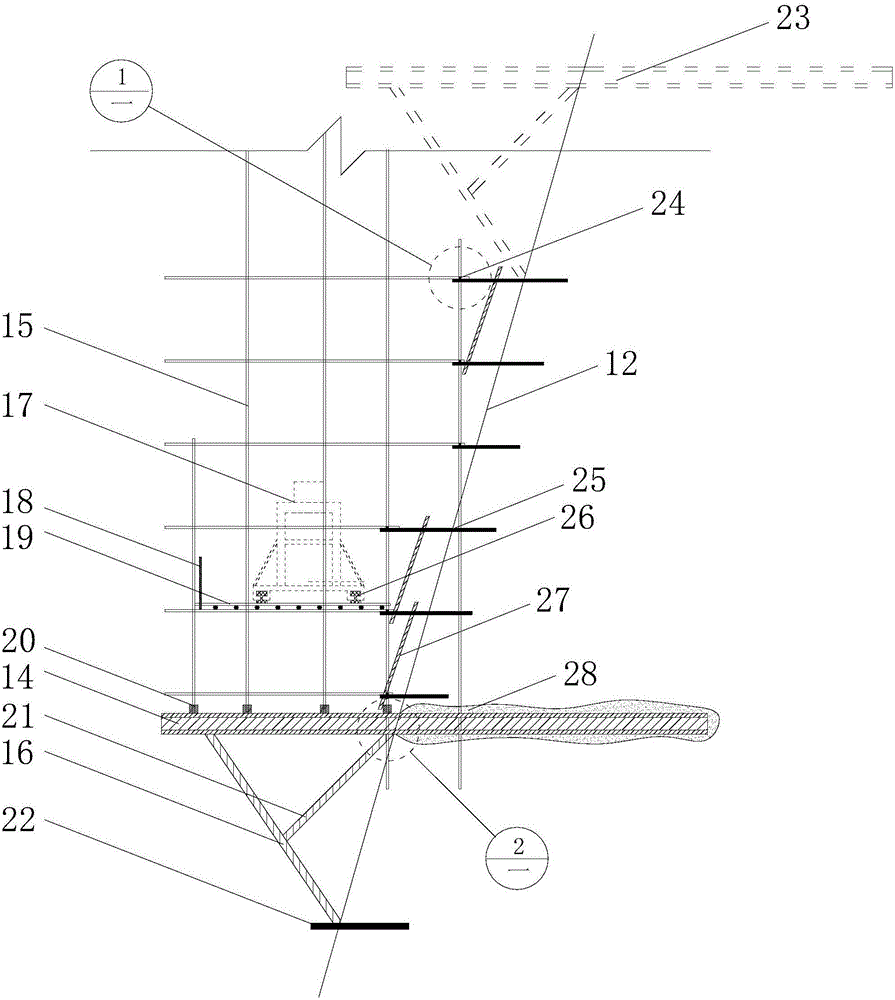

[0041] figure 1 It is a sectional view of the complex and steep cliff deep slope comprehensive support structure of the present invention, figure 2 It is a schematic diagram of setting up the operation platform of the comprehensive support structure of the complex steep cliff and deep slope of the present invention, image 3 It is a schematic diagram of the connection between the operating frame and the cliff, Figure 4 yes image 3 Middle node 1 large sample diagram, Figure 5 yes image 3 Middle node 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com