CO2 recycling and reusing device after gas well CO2 hydrofracture

A gas well and fracturing technology, which is applied in the field of CO2 recovery and reuse devices after CO2 hydraulic fracturing in gas wells, can solve problems such as aggravating the greenhouse effect and increasing fracturing costs, and achieve the effects of reducing costs, reducing emissions, and reducing environmental protection risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

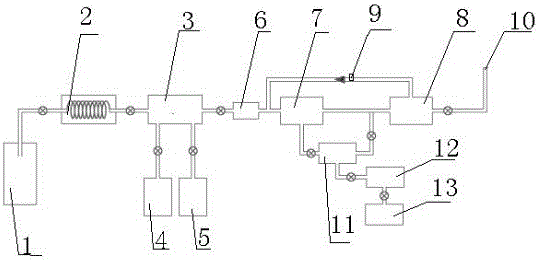

[0025] In order to overcome the open fracturing fluid flowback of existing devices, resulting in CO 2 escape into the atmosphere to aggravate the greenhouse effect and increase the cost of fracturing, the present invention provides such as figure 1 A gas well shown CO 2 CO after hydraulic fracturing 2 Recycling and reuse device, the present invention de-sands and dehydrates the flow-back liquid through manifold step-down and sand-gas-liquid three-phase separator, and then separates CO through three separation membranes 2 and natural gas (CH 4 ), to achieve lower CO 2 emissions while achieving CO 2 The purpose of recycling and comprehensive utilization.

[0026] A gas well CO 2 The liquid drainage control device after fracturing includes a solid-gas-liquid separator 3, one end of the solid-gas-liquid separator 3 is connected to the gas well 1; the lower end of the solid-gas-liquid separator 3 is connected to a collector for separated solids and liquids, The gas outlet o...

Embodiment 2

[0032] Based on Example 1, in this example, the collectors connected to the lower end of the solid-gas-liquid separator 3 are the fracturing sand collector 4 and the fracturing fluid collector 5 .

[0033] A depressurization retarder 2 is connected between the gas well 1 and the solid-gas-liquid separator 3 .

[0034] In the present invention, once the fracturing of the gas well 1 is completed, the flowback liquid produced from the well passes through the liquid deceleration and depressurization device 2 to throttle the pipeline to protect the downstream test production equipment by reducing the pressure and slowing down the flow rate. After passing through the liquid deceleration and depressurization device 2, the liquid first flows to a solid-liquid-gas three-phase separator 3, and the flowback liquid passes through the solid-liquid-gas three-phase separator 3, and the backflow fracturing fluid in the fracturing flowback liquid is separated by sedimentation The sand is colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com