Vibration-excitation-vibration-absorption traveling wave guide microfluid delivery device

A microfluidic and traveling wave technology, applied in liquid variable volume machinery, pumps with flexible working elements, machines/engines, etc., can solve the problem of fluid and pipe wall materials, physical and chemical properties that are only applicable to a certain range. Sensitivity and other issues, to achieve the effect of improving thermal diffusion efficiency, high integration, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

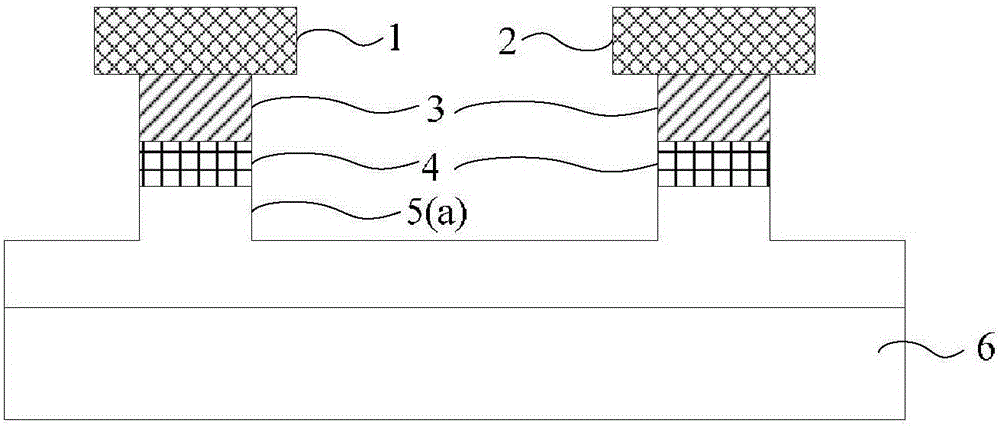

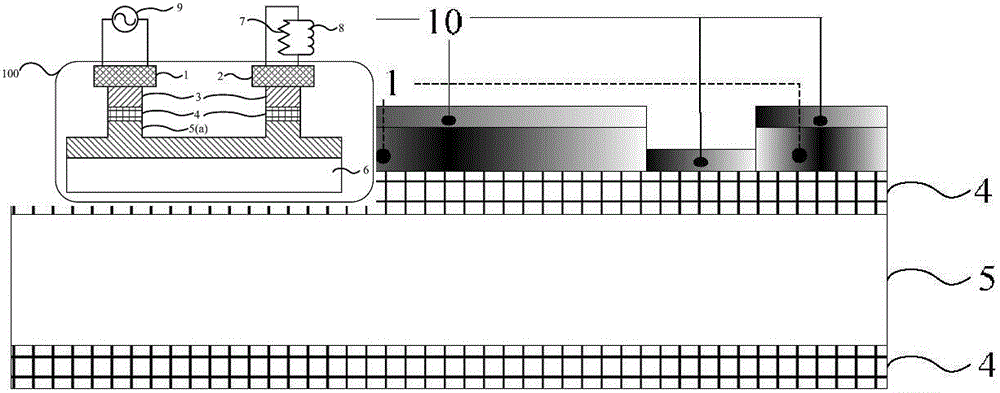

[0024] The core component of the present invention is the processing and production of the ultrasonic traveling wave driving micro device (100), and the core idea of the present invention is to bond the PZT-4 sheet (1) and PZT-4 on the ultrasonic traveling wave driving micro device (100). The thin slice (2) can generate a unidirectional linear propagation ultrasonic traveling wave, which can be realized by the following technical solutions:

[0025] 1) Cleaning of silicon wafer

[0026] The first step is to clean the second silicon wafer (5). The purpose of the cleaning treatment is to clean and dry the surface of the second silicon wafer (5) so as to be closely integrated with the subsequent process.

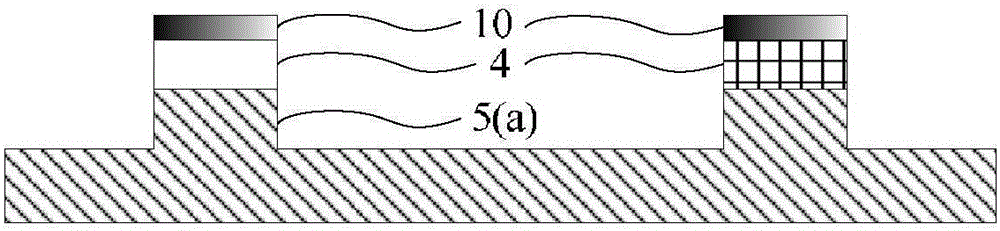

[0027] 2) Si 3 N 4 Film production

[0028] This device uses Si 3 N 4 As the required film material. In the ultrasonic traveling wave driven micro device (100), low-pressure chemical vapor deposition (LPCVD) is used to perform low-stress Si on the second silicon wafer (5) in the LP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com