A magnetorheological precision machine tool vibration isolator

A precision machine tool and magneto-rheological technology, applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of poor low-frequency vibration isolation ability, achieve the effect of reducing natural frequency and solving low-frequency vibration isolation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

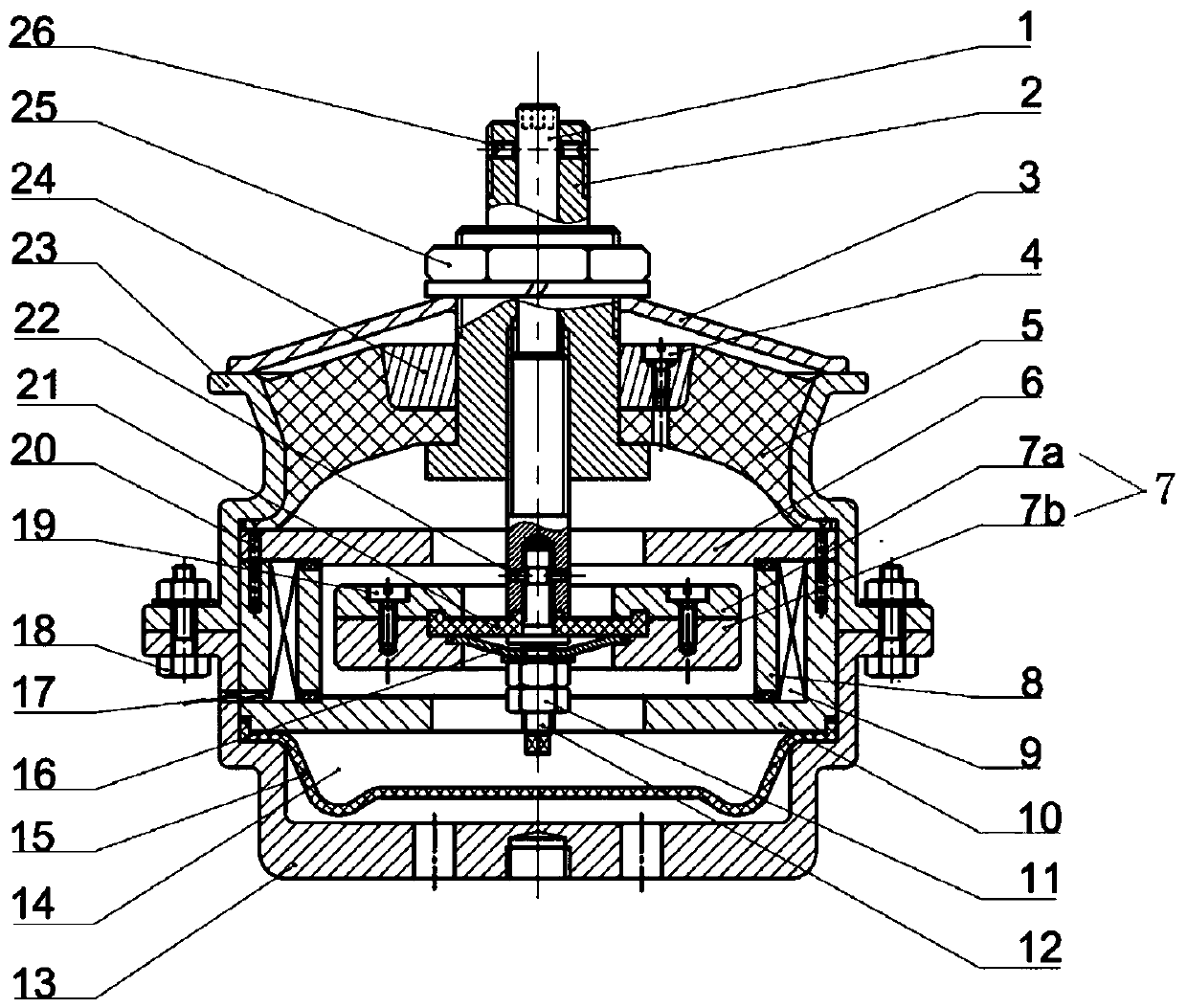

[0018] Embodiments of magnetorheological precision machine tool vibration isolators of the present invention: as figure 1 As shown, the magnetorheological precision machine tool vibration isolator includes a shell with an upward opening for containing magnetorheological fluid, a piston rod, a rubber main spring 5 and an upper butterfly spring 3 . The housing includes an upper housing 23 and a lower housing 13 which are detachably connected together by bolts 18 . The rubber main spring 5 is assembled in the opening of the housing, the piston rod is installed on the rubber main spring 5 along the up and down direction, the upper butterfly spring 3 is located above the rubber main spring 5, and the piston rod is also equipped with a valve for adjusting the upper butterfly spring. 3 Nut 25 to make it in a state of negative stiffness. The upper thread of the piston rod is equipped with an adjusting sleeve 2 for adjusting the vertical displacement of the piston rod. The upper butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com