Wireless power supply warm keeping device

A technology of wireless power supply and power supply, applied in the field of heating devices, can solve the problems of local overheating, low efficiency of wireless power supply heating devices, easy leakage and fire, etc., to achieve uniform heating, simplify temperature sensing control devices, and improve heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

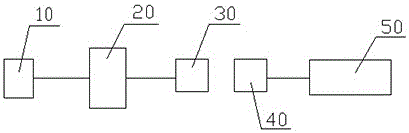

[0015] Embodiment 1, as shown in Figure 1, the power supply 10 and the frequency generation module 20 are connected by wires, the power output current generates high-frequency alternating current through the frequency generation module 20, the alternating current generates electromotive force through the transmitting coil 30, and passes through the inductance of the receiving coil 40 Coupling, the current is transmitted to the receiving coil 40, and output to the PC substrate heating sheet 50 for heating, wherein a switch is provided on the power supply 10 to control the on-off of the circuit.

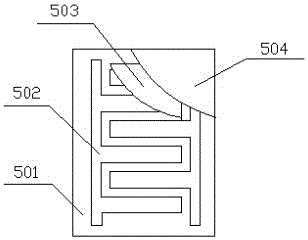

[0016] PC substrate heater 50, such as figure 2 As shown, a silver paste layer 502 is printed on the first PC substrate 501 according to a preset pattern by screen printing, and baked at 120°C for 20 minutes to form a conductive layer; The mass printed carbon paste layer 503 was baked at 120°C for 20 minutes to form a heat generating layer; an adhesive was applied around the first PC ...

Embodiment 2

[0018] Embodiment 2, the power supply 10 and the frequency generating module 20 are connected by wires, the power supply outputs current, and the frequency generating module 20 generates high-frequency alternating current, and the alternating current generates electromotive force through the transmitting coil 30, and through the inductive coupling with the receiving coil 40, the current is transmitted to The receiving coil 40 is output to the PET substrate heating sheet for heating, wherein a switch is provided on the power supply 10 to control the on-off of the circuit.

[0019] PET substrate electric heating sheet, print the silver paste layer on the first PET substrate by screen printing according to the preset pattern, bake at 150°C for 15 minutes to form a conductive layer; use screen printing on the silver paste layer according to the preset pattern Pattern printed carbon paste layer, baked at 150°C for 15 minutes to form a heat-generating layer; apply adhesive around the...

Embodiment 3

[0021] Embodiment 3, the power supply 10 and the frequency generating module 20 are connected by wires, the power supply outputs current, and the frequency generating module 20 generates high-frequency alternating current, and the alternating current generates electromotive force through the transmitting coil 30, and through the inductive coupling with the receiving coil 40, the current is transmitted to The receiving coil 40 is output to the PBT substrate electric heater for heating, wherein a switch is provided on the power supply 10 to control the on-off of the circuit.

[0022] PBT base material electric heater, print the silver paste layer on the first PBT base material by screen printing according to the preset pattern, bake at 150°C for 15min to form a conductive layer; use screen printing on the silver paste layer according to the preset pattern Pattern printed carbon paste layer, baked at 150°C for 15 minutes to form a heat-generating layer; apply adhesive around the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com