Method for installing air atomizing nozzle of sprinkler system at refrigeration station based on Fluent software

A spray system and air atomization technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of installation conditions that do not consider the position and quantity of nozzles, and the lack of scientific data of nozzle working parameters, etc., to achieve Intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044] The method of installing the air atomizing nozzle of the spray system of the refrigeration station based on the Fluent software in this embodiment combines figure 1 A flow chart of the shown simulation method, said method comprising the following steps:

[0045] Step 1. Set the parameters of the physical model in the refrigeration station according to the actual situation: the size of the physical prototype, the position of the nozzle, the distance between the nozzles, the working pressure of the spray system and the spray angle of the nozzle;

[0046] Among them, the physical prototype refers to the spray system of the refrigeration station to be installed with air atomizing nozzles;

[0047] Step 2. According to the physical model parameters in the refrigeration station determined in step 1, build a custom function:

[0048] 1) According to the functional relationship between the nozzle outlet working pressure of the spray system and the droplet size, construct a cus...

specific Embodiment approach 2

[0075] Different from the specific embodiment one, the method of installing the air atomizing nozzle of the spray system of the refrigeration station based on Fluent software in this embodiment, the function of the nozzle outlet working pressure of the spray system described in step two and the droplet particle size The relationship is:

[0076] r = d i ΔP 0.37 s i n α 2

[0077] In the formula, d i is the nozzle outlet diameter, in meters; ΔP is the nozzle outlet pressure, in Pa; α is the nozzle angle, α=90°.

specific Embodiment approach 3

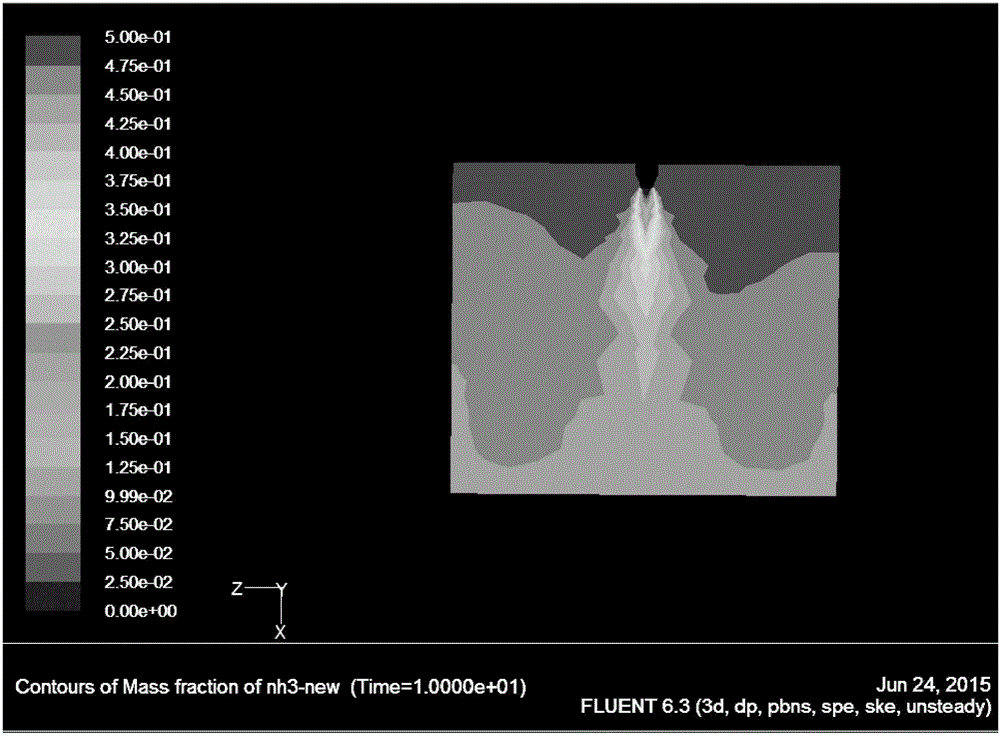

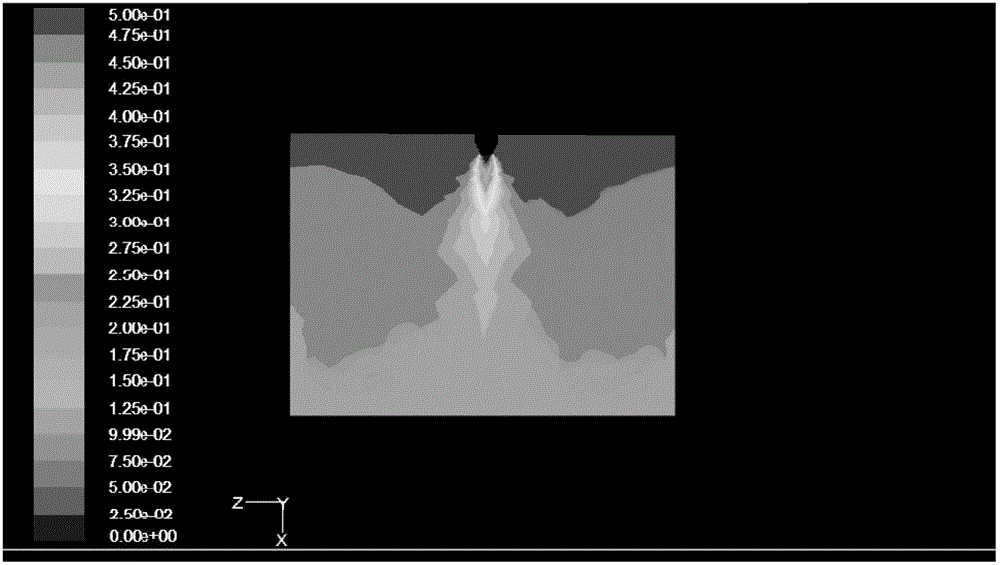

[0078] The difference from specific embodiment 1 or 2 is that in the method of installing the air atomizing nozzle of the refrigeration station spray system based on Fluent software in this embodiment, in the characteristics of the chemical reaction between ammonia gas and water described in step 2, the ammonia involved The relationship between gas and water chemical reaction rate is:

[0079] N A = 0.75 Sc 1 / 3 Re G 1 / 2 D A B d p R T ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com