A kind of LED chip structure and preparation method thereof

A chip structure and buffer layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of low hole injection efficiency, improve ohmic contact characteristics, increase hole injection efficiency, and reduce the width of the depletion layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

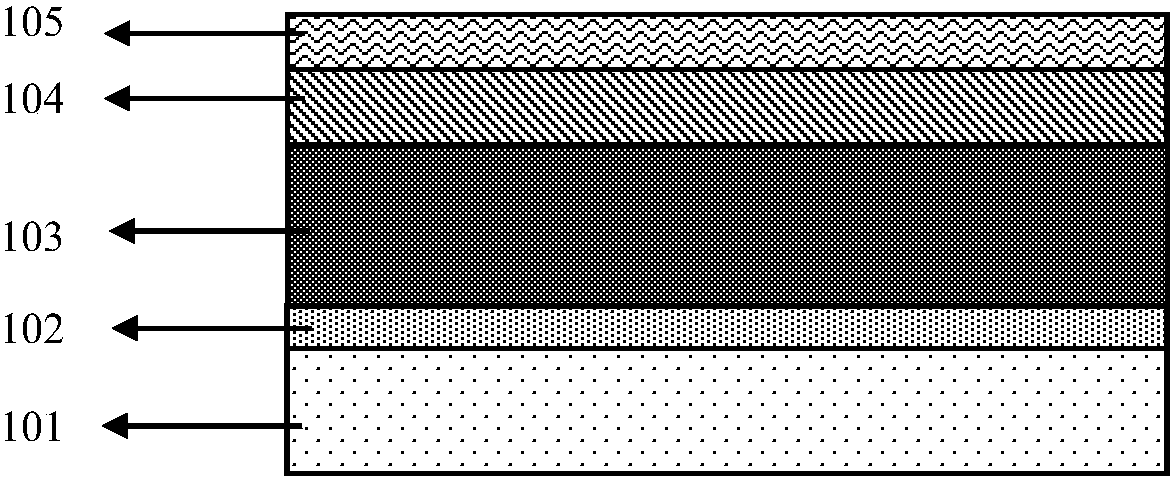

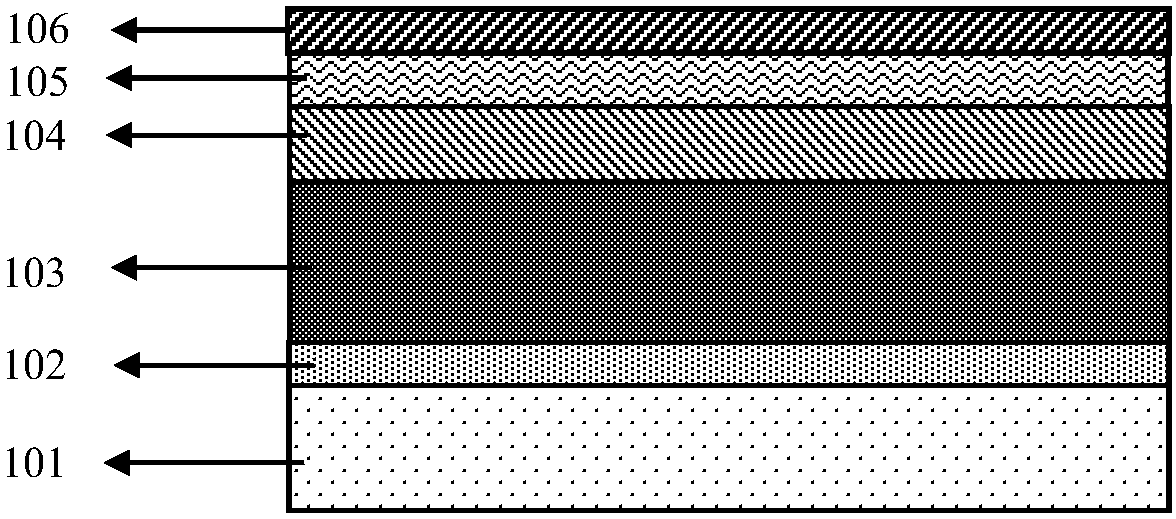

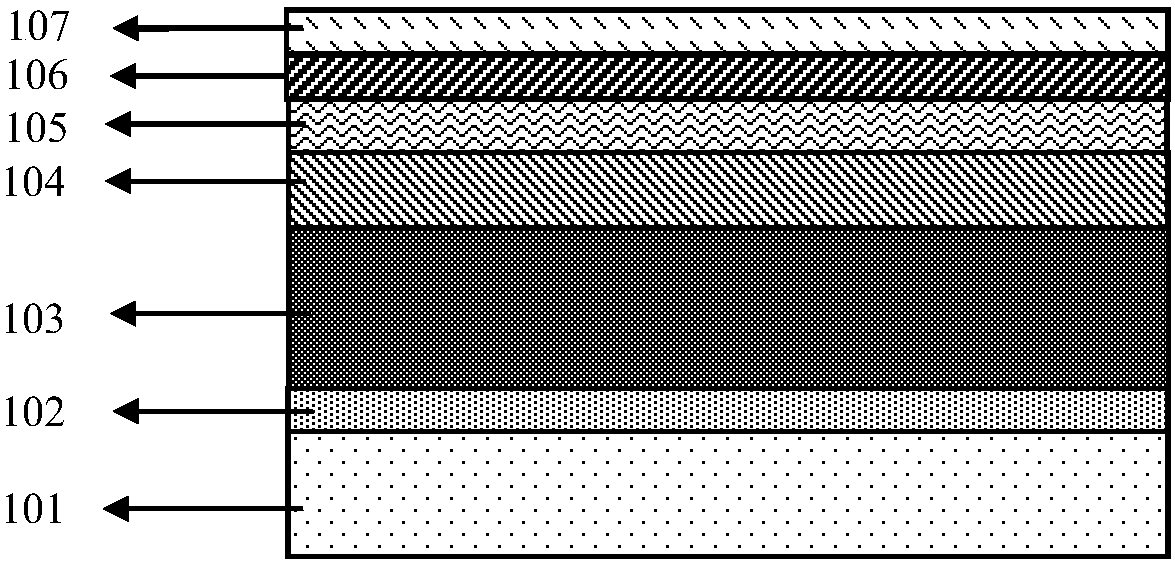

[0047] The chip structure of a kind of LED of this embodiment comprises substrate 101, buffer layer 102, N-type semiconductor material 103, N-type ohmic electrode 109 formed on N-type semiconductor material 103, multi-quantum well layer 104 in order from bottom to top , P-type semiconductor material 105, insulating layer 106, current spreading layer 107 and P-type ohmic electrode 108, wherein the insulating layer 106 is made of AlN with a thickness of 0.5nm, and the insulating layer 106 is a continuous film structure.

[0048] Among the above, the substrate 101 is sapphire; the material of the buffer layer 102 is InN, and the thickness is 10nm; the material of the N-type semiconductor material 103 is InN. 0.9 Ga 0.1 N, with a thickness of 2 μm; the material of the multi-quantum well layer 104 is InN / In 0.9 Ga 0.1 N, where the quantum barrier In 0.9 Ga 0.1 The thickness of N is 5nm, and the thickness of quantum well InN is 1nm; The material of P-type semiconductor material ...

Embodiment 2

[0059] The chip structure of a kind of LED of this embodiment comprises substrate 101, buffer layer 102, N-type semiconductor material 103, N-type ohmic electrode 109 formed on N-type semiconductor material 103, multi-quantum well layer 104 in order from bottom to top , P-type semiconductor material 105, insulating layer 106, current spreading layer 107 and P-type ohmic electrode 108, wherein the material used for insulating layer 106 is SiO 2 , with a thickness of 10 nm, the insulating layer 106 has a discontinuous film structure, and the discontinuous film structure is produced by photolithography.

[0060] Among the above, the substrate 101 is Si; the material of the buffer layer 102 is GaN, and the thickness is 30nm; the material of the N-type semiconductor material 103 is GaN, and the thickness is 5 μm; the material of the multi-quantum well layer 104 is In 0.25 Ga 0.75 N / GaN, where the thickness of the quantum barrier GaN is 26nm, and the quantum well In 0.25 Ga 0.75 ...

Embodiment 3

[0071] The chip structure of a kind of LED of this embodiment comprises substrate 101, buffer layer 102, N-type semiconductor material 103, N-type ohmic electrode 109 formed on N-type semiconductor material 103, multi-quantum well layer 104 in order from bottom to top , P-type semiconductor material 105, insulating layer 106, current spreading layer 107 and P-type ohmic electrode 108, wherein the insulating layer 106 is made of SiN with a thickness of 20nm, and the insulating layer 106 is a continuous film structure.

[0072] Among the above, the substrate 101 is SiC; the material of the buffer layer 102 is AlN, and the thickness is 50nm; the material of the N-type semiconductor material 103 is AlN, and the thickness is 8 μm; the material of the multi-quantum well layer 104 is Al 0.9 Ga 0.1N / AlN, where the thickness of the quantum barrier AlN is 50nm, and the quantum well Al 0.9 Ga 0.1 The thickness of N is 10nm; The material of P-type semiconductor material 105 is AlN, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com