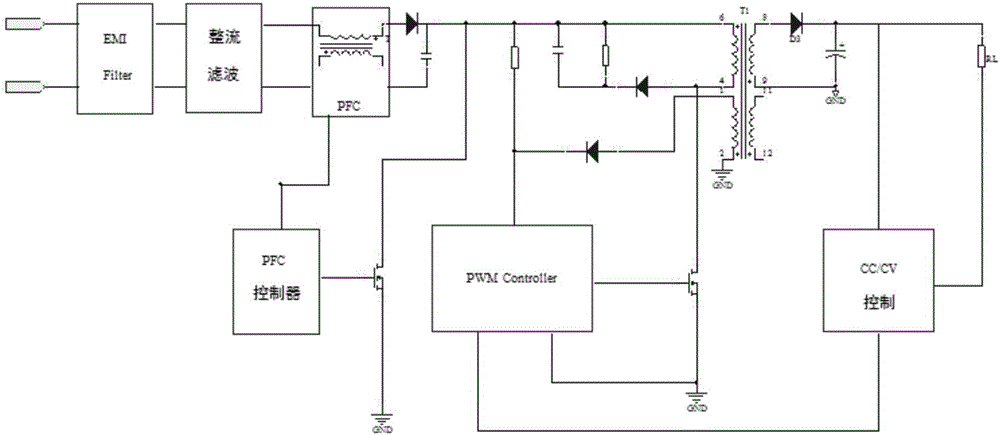

Switching power supply feedback control circuit and single-stage PFC efficient constant current power supply drive circuit

A switching power supply and feedback control technology, applied in the field of electronics, can solve the problems of inability to eradicate 100HZ ripple, low output current ripple, and inability to take into account low ripple, etc., achieving high cost performance, large volume, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

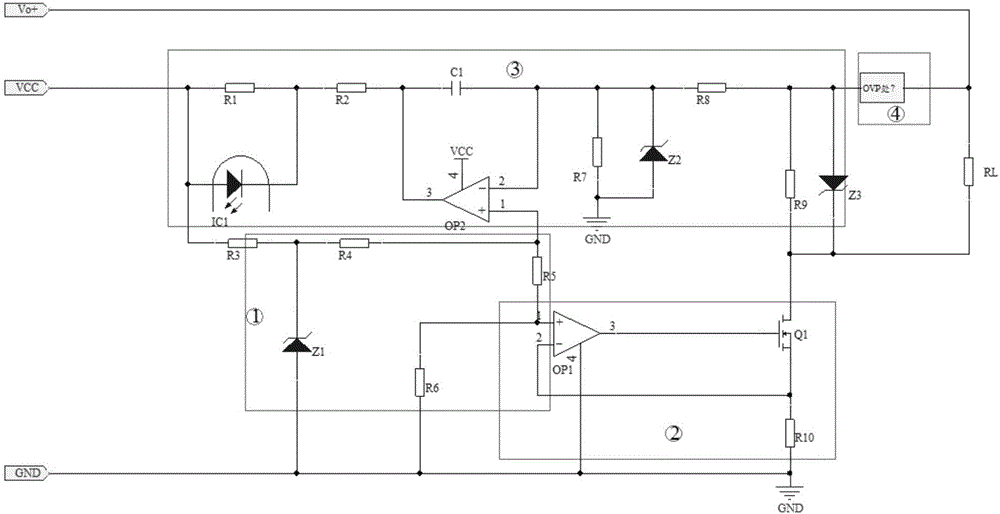

[0042] see figure 2 , which shows the specific circuit schematic diagram of the switching power supply feedback control circuit for constant current and constant voltage to eliminate ripple provided by this example. It can be seen from the figure that the constant current feedback circuit of this embodiment includes a resistor R1, a resistor R2, a resistor R3, a resistor R4, a resistor R5, a resistor R6, a resistor R7, a resistor R8, a resistor R9, a resistor R10, a capacitor C1, Zener diode Z1, Zener diode Z2, Zener diode Z3, MOS transistor Q1, OVP processing module, optocoupler IC1, operational amplifier OP1, operational amplifier OP2 and load RL.

[0043] The power supply terminal of the operational amplifier OP2, the anode of the optocoupler IC1 at one end of the resistor R1 and one end of the resistor R3 are connected to the output terminal VCC of the power supply module;

[0044] The positive end of the Zener diode Z1, one end of the resistor R6, the ground end of the ...

example 2

[0066] In this example, on the basis of Example 1, the Zener diode Z1 is replaced by a three-terminal Zener tube.

[0067] In contrast, Zener diodes are cheap, PCB wiring is simple, and three-terminal Zener tubes have higher precision.

example 3

[0069] In this example, on the basis of Example 1, the Zener diode Z2 and the Zener diode Z3 are removed, and only the resistor R7 and the resistor R9 are used.

[0070] At this time, the functions of the resistors R7 and R9 are not changed, and the output accuracy is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com