Mining conveying adhesive tape water removal cleaning device

A cleaning device and tape technology, applied in the field of machinery, can solve problems such as hidden safety hazards in mine production, conveyors not working properly, transportation system outages for maintenance, etc., so as to reduce the number of shutdowns for cleaning, eliminate slippage, and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

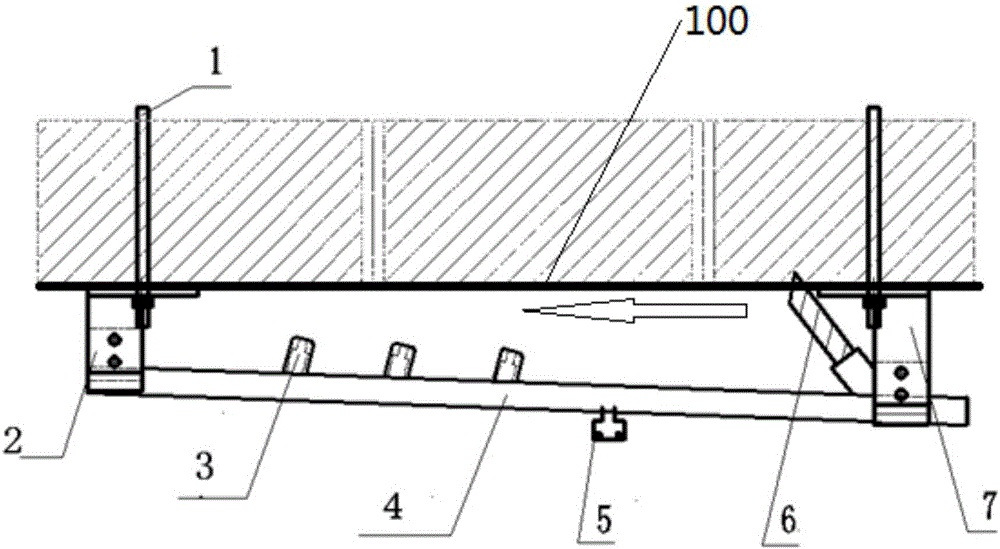

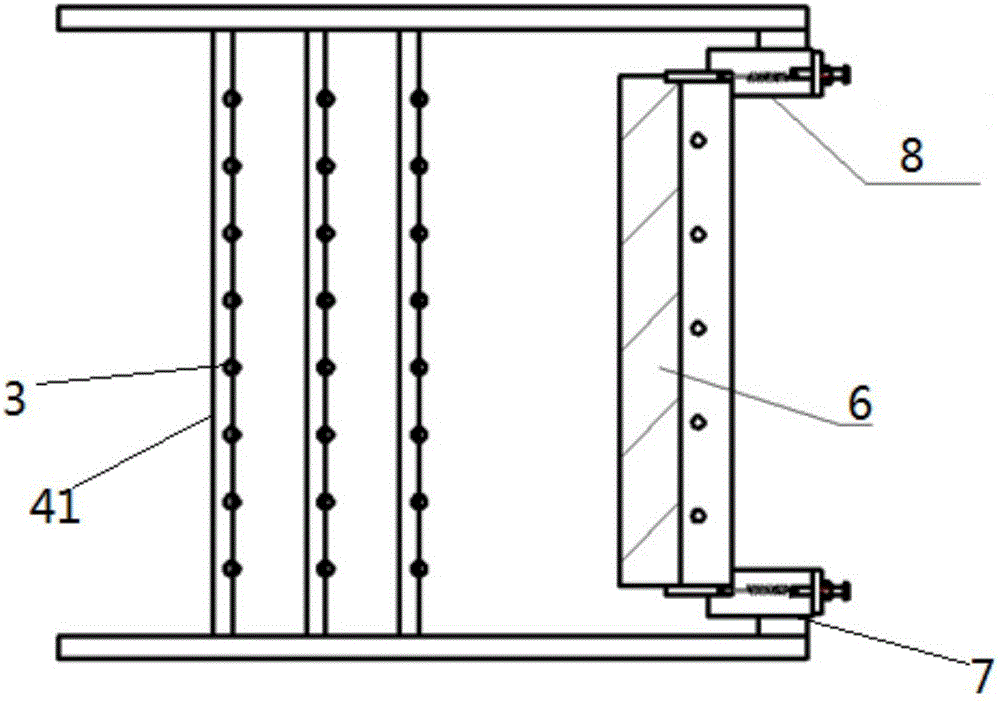

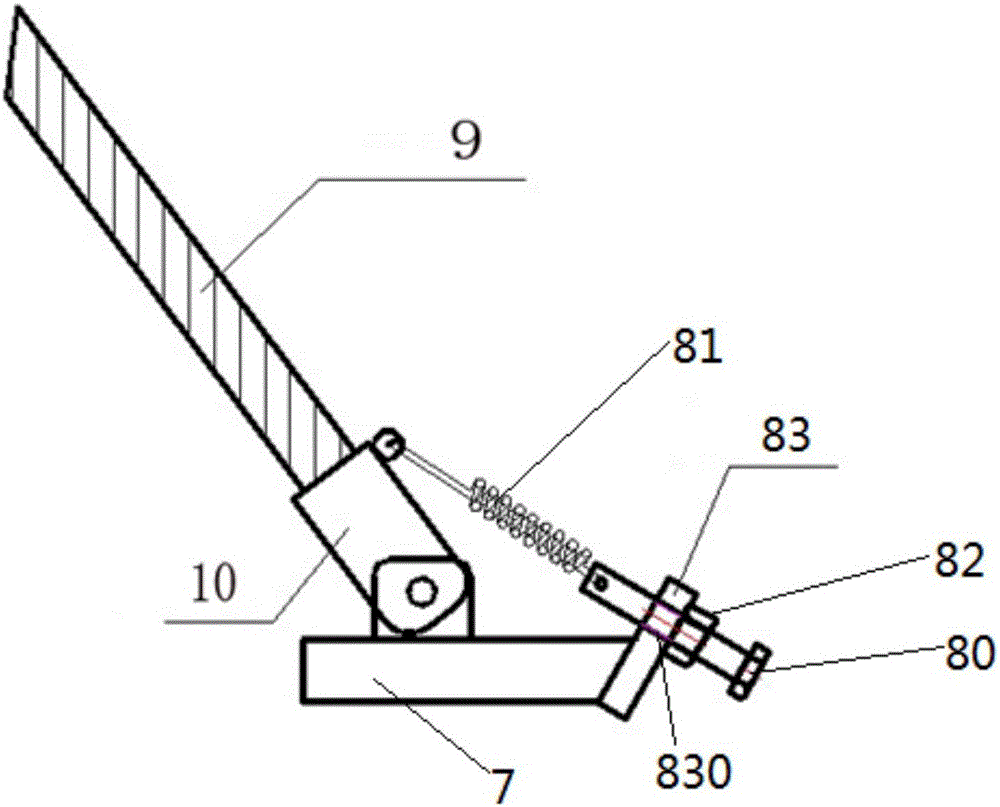

[0025] see Figure 1 to Figure 4 As shown in (d), a mine conveyor belt dewatering and cleaning device of the present invention includes a front positioning frame 2, a rear positioning frame 7, a nozzle frame 4 and a cleaning device 6.

[0026] The nozzle frame 4 is fixed between the front positioning frame 2 and the rear positioning frame 7, and the nozzle frame 4 is provided with three rows of nozzle installation pipes 41; the nozzle installation pipe is equipped with an air flow dewatering nozzle 3; The air pipe joint 5 communicates with three hollow nozzle installation pipes. A cleaning device 6 is installed on the rear positioning frame 7 .

[0027] The front positioning frame 2 and the rear positioning frame 7 fixedly install the entire mining conveyor belt water removal and cleaning device below the conveyor belt 100 through the fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com