Sintered brick setting machine

A brick stacking machine and rack technology, which is applied in the field of stacking equipment for sintered bricks, can solve the problems of extrusion damage, easy shaking, and high humidity of bricks, so as to improve stacking quality and stacking efficiency, and prevent extrusion damage. damage and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

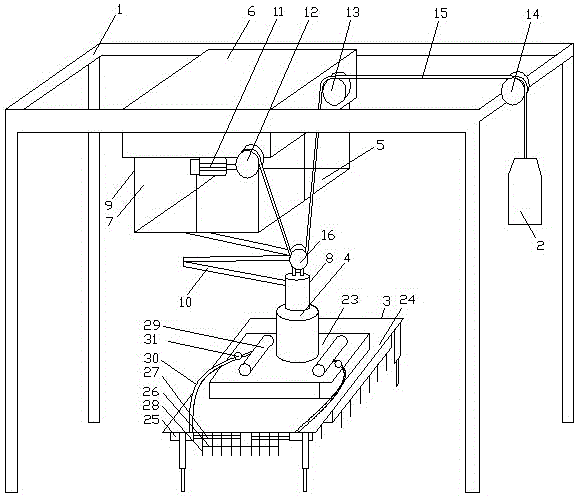

Embodiment 1

[0032] see figure 1 , a sintered brick stacking machine, comprising a frame 1, a counterweight 2, a blank clamping device 3, a rotating device 4, a lifting device 5 and a running device 6, the running device 6 is slidably connected to the beam of the frame 1, the The lifting device 5 includes a balance frame 7 and a lifting part 8, and the balance frame 7 is composed of a vertical frame 9 and a multi-link telescopic frame 10 below the running device 6, and one end of the multi-link telescopic frame 10 slides with the vertical frame 9 connected, the other end is fixedly connected with the rotating device 4, and the lifting part 8 is composed of a servo motor 11, a driving sprocket 12, a first fixed pulley 13, a second fixed pulley 14, a chain 15 and a driven sprocket 16. Servo motor 11, driving sprocket 12 and first fixed pulley 13 are all arranged on the traveling device 6, second fixed pulley 14 is arranged on the beam end of frame 1, and described driven sprocket 16 is arran...

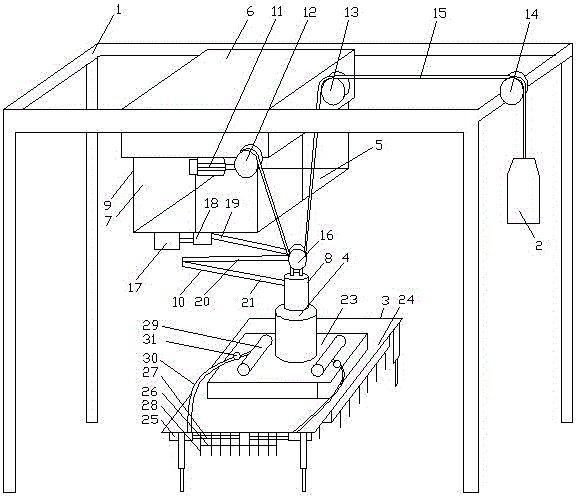

Embodiment 2

[0035] see figure 2 , a sintered brick stacking machine, comprising a frame 1, a counterweight 2, a blank clamping device 3, a rotating device 4, a lifting device 5 and a running device 6, the running device 6 is slidably connected to the beam of the frame 1, the The lifting device 5 includes a balance frame 7 and a lifting part 8, and the balance frame 7 is composed of a vertical frame 9 and a multi-link telescopic frame 10 below the running device 6, and one end of the multi-link telescopic frame 10 slides with the vertical frame 9 connected, the other end is fixedly connected with the rotating device 4, and the lifting part 8 is composed of a servo motor 11, a driving sprocket 12, a first fixed pulley 13, a second fixed pulley 14, a chain 15 and a driven sprocket 16. Servo motor 11, driving sprocket 12 and first fixed pulley 13 are all arranged on the traveling device 6, second fixed pulley 14 is arranged on the beam end of frame 1, and described driven sprocket 16 is arra...

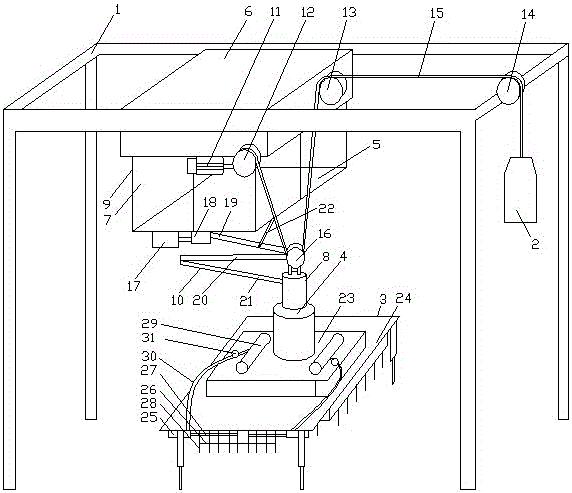

Embodiment 3

[0040] see image 3 , a sintered brick stacking machine, comprising a frame 1, a counterweight 2, a blank clamping device 3, a rotating device 4, a lifting device 5 and a running device 6, the running device 6 is slidably connected to the beam of the frame 1, the The lifting device 5 includes a balance frame 7 and a lifting part 8, and the balance frame 7 is composed of a vertical frame 9 and a multi-link telescopic frame 10 below the running device 6, and one end of the multi-link telescopic frame 10 slides with the vertical frame 9 connected, the other end is fixedly connected with the rotating device 4, and the lifting part 8 is composed of a servo motor 11, a driving sprocket 12, a first fixed pulley 13, a second fixed pulley 14, a chain 15 and a driven sprocket 16. Servo motor 11, driving sprocket 12 and first fixed pulley 13 are all arranged on the traveling device 6, second fixed pulley 14 is arranged on the beam end of frame 1, and described driven sprocket 16 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com