Jet regulator

A technology of jet regulator and jet decomposer, which is applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of jet regulator design and manufacturing cost, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

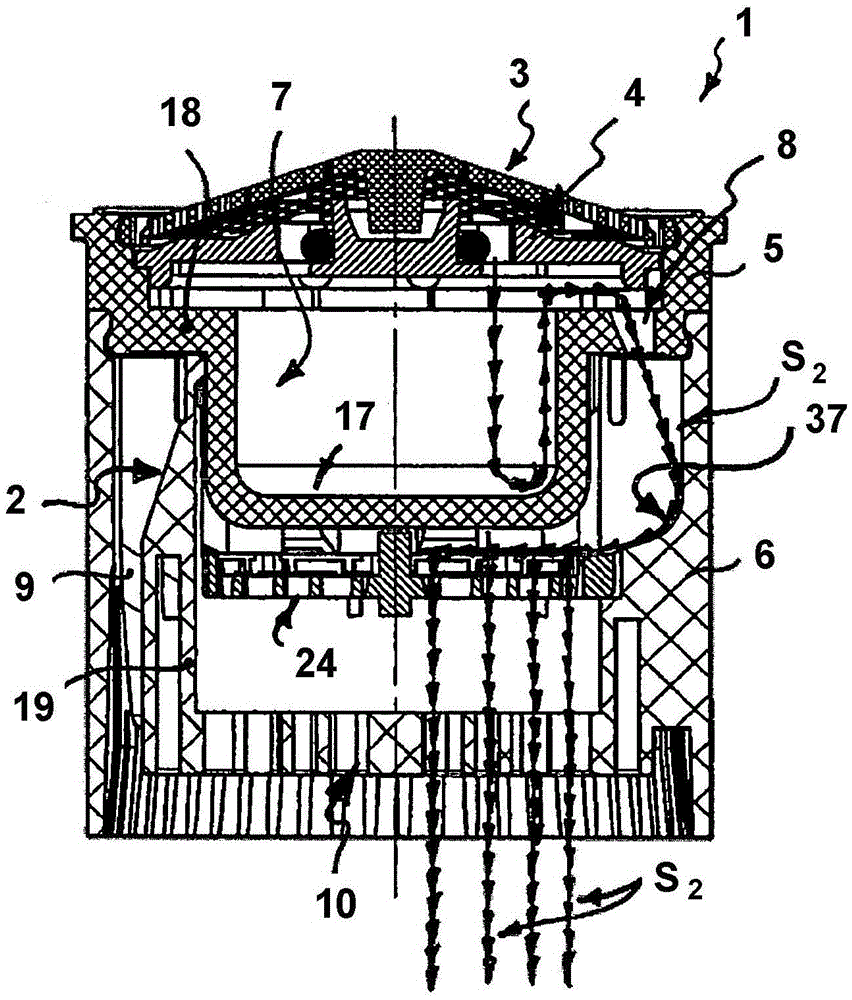

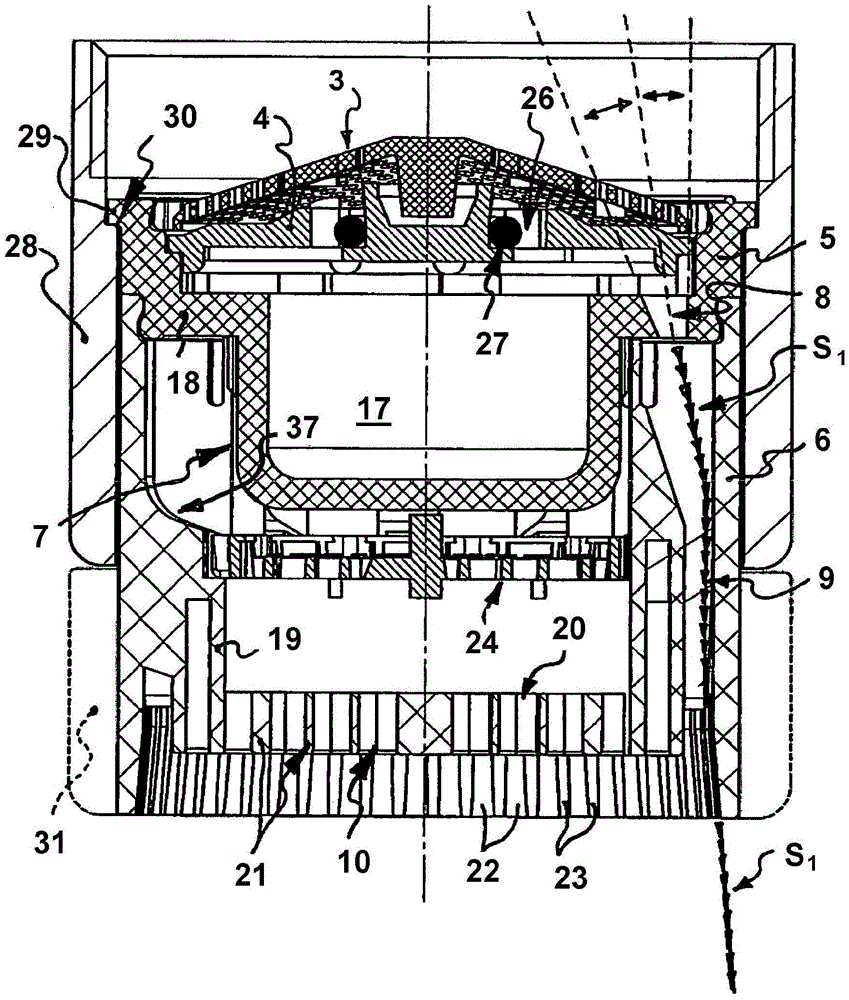

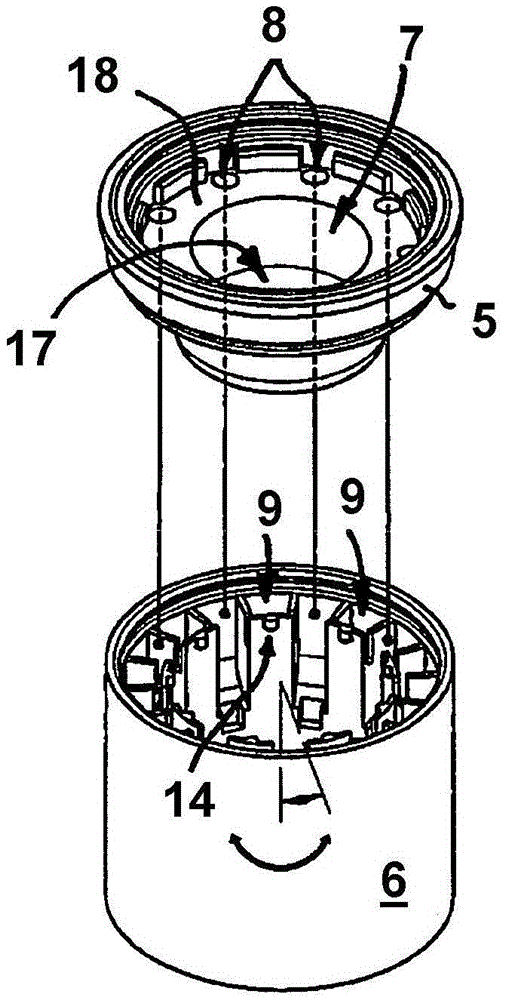

[0084] exist Figures 1 to 29 Two implementations 1, 1' of the built-in unit for hygiene are shown in . as in figure 2 As shown in the example, the built-in unit 1, 1' can be assembled by means of an outflow connection part 28 on the water outlet of a sanitary water tap not shown further here. The built-in unit 1, 1' has a jet regulator 2, 2' on the outflow side, which can be selectively switched between two outflow jet patterns (see figure 1 , 2 as well as Figure 24 , 25 ) to switch between. The built-in unit 1, 1' has an inflow-side pre-sieve or filter sieve 3, 3' which is able to filter calcium salt particles or dirt particles contained in the inflow water Otherwise, the calcium salt particles or dirt particles would otherwise be fixed in the built-in unit 1, 1' and interfere with its function. In order to be able to adjust the amount of water flowing through the built-in unit 1, 1' per unit time to a fixed maximum value independently of the pressure, between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com