A flexible temperature sensor based on pectin/xanthan gum blend film and its preparation method

A technology of temperature sensor and xanthan gum, which is applied in the field of sensors, can solve the problems that flexible sensors are not biodegradable, not suitable for human body temperature detection, and difficult to obtain raw materials, etc., and achieve real-time monitoring of human body temperature changes, simple structure, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the flexible temperature sensor based on the pectin / xanthan gum blend film of the present invention comprises the following steps:

[0027] Step 1, preparing pectin sol.

[0028] Specifically, the pectin powder was dissolved in deionized water at 80° C. and stirred at a speed of 800 rpm until a uniform pectin sol with a concentration of 2% w / v was obtained.

[0029] Step 2, preparing a blend system solution.

[0030] In one embodiment, xanthan gum at a concentration of 0.3% w / v and 0.6 mL of glycerol are added to the pectin sol, and stirred at a speed of 1000 rpm to form a uniform blend system solution.

[0031] Step 3, preparing the mixed system sol.

[0032] In one embodiment, a 32 mM calcium chloride solution is configured in deionized water at a temperature of 80° C., wherein R=[Ca 2+ ] / 2[COO - ]=1, R is the molar ratio, the calcium chloride solution is added dropwise in the blending system solution by titration, and is stirred at a spe...

Embodiment 1

[0051] Fabrication of pectin / xanthan gum blend film flexible temperature sensor and testing of its sensing characteristics

[0052] The difference between the present embodiment one and the comparative example one is that before adding sodium chloride solution in step 2, add 0.3% (w / v) xanthan gum and plasticizer glycerin 0.6mL, stirring speed is 1000rpm, the rest The steps are the same as in Comparative Example 1.

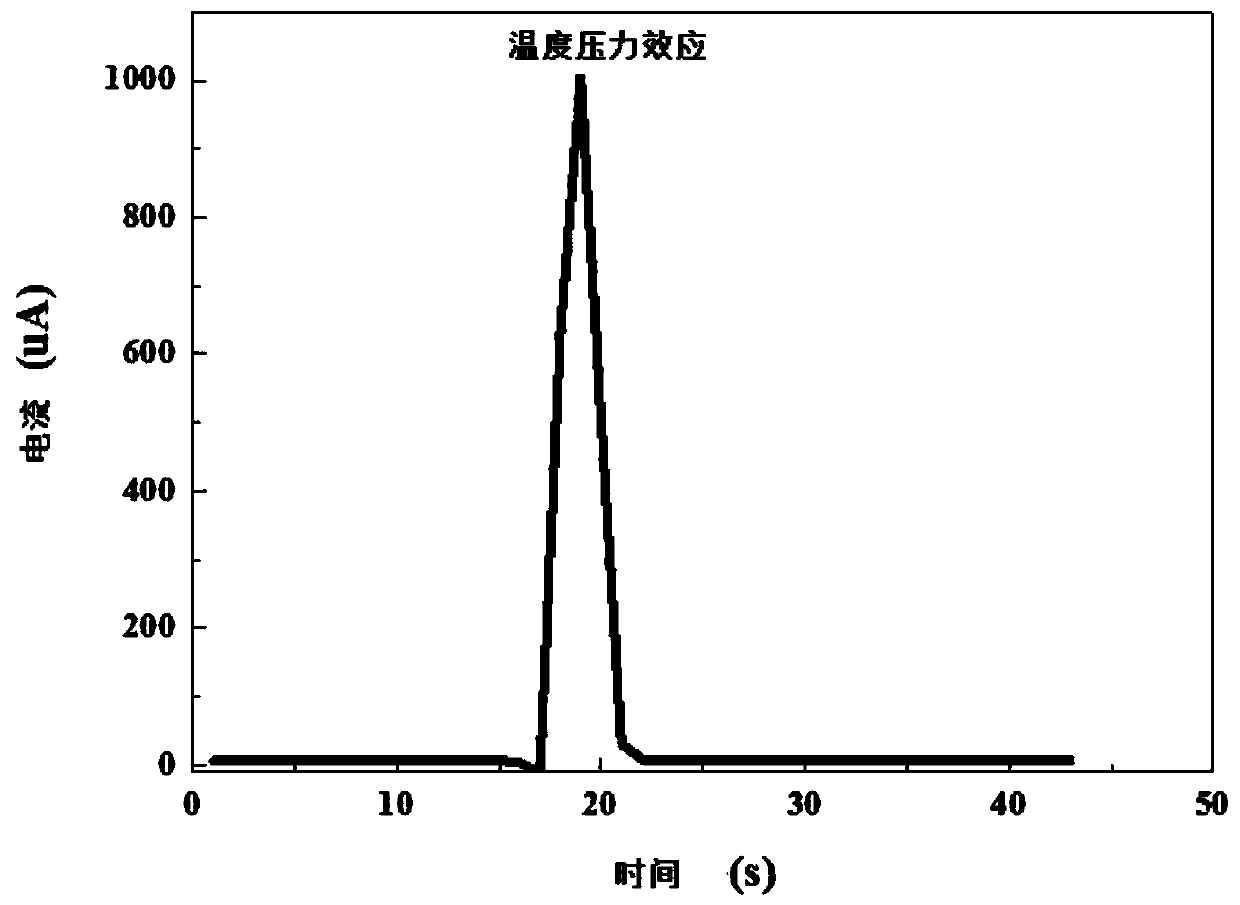

[0053] The responsiveness performance reference of this embodiment figure 2 , figure 2 It is the time response curve of the flexible temperature sensor based on the pectin / xanthan gum blend film in the present invention. like figure 2 As shown, it can be seen that its temperature response is high and its performance is good.

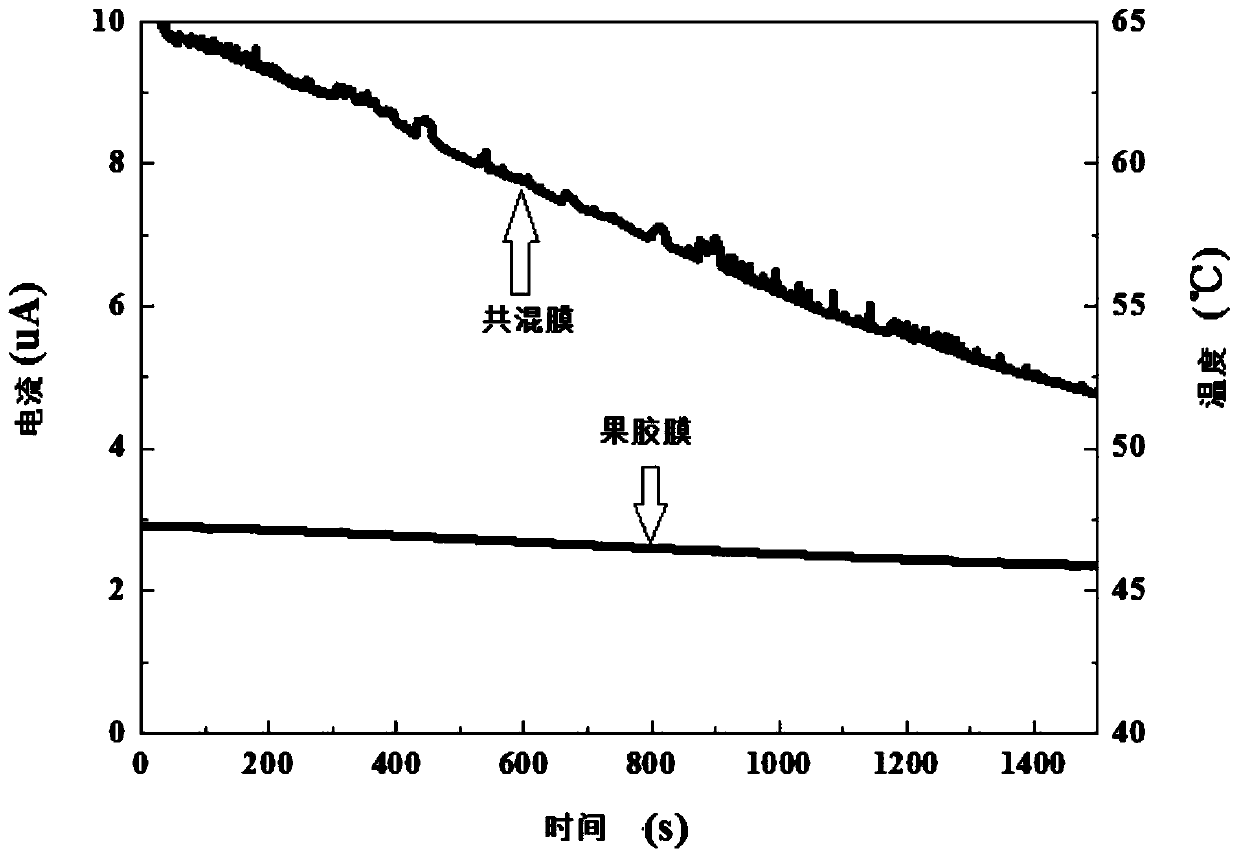

[0054] For the results of the performance tests of the above two examples, please continue to refer to image 3 , image 3 It is a sensitivity comparison chart of the flexible temperature sensor based on the pectin / xanthan gum blend...

Embodiment 2

[0056] Fabrication of pectin / xanthan gum blend film flexible temperature sensor and testing of its sensing characteristics

[0057] The difference between the second embodiment and the first embodiment is that the thickness of the flexible substrate layer prepared in step 1 is about 550 μm, the thickness of the flexible temperature-sensitive layer prepared in step 2 is 90 μm, and the rest of the steps are the same as in the first embodiment .

[0058] The response performance of this embodiment is similar to that of the first embodiment: the temperature response is very high and the performance is good.

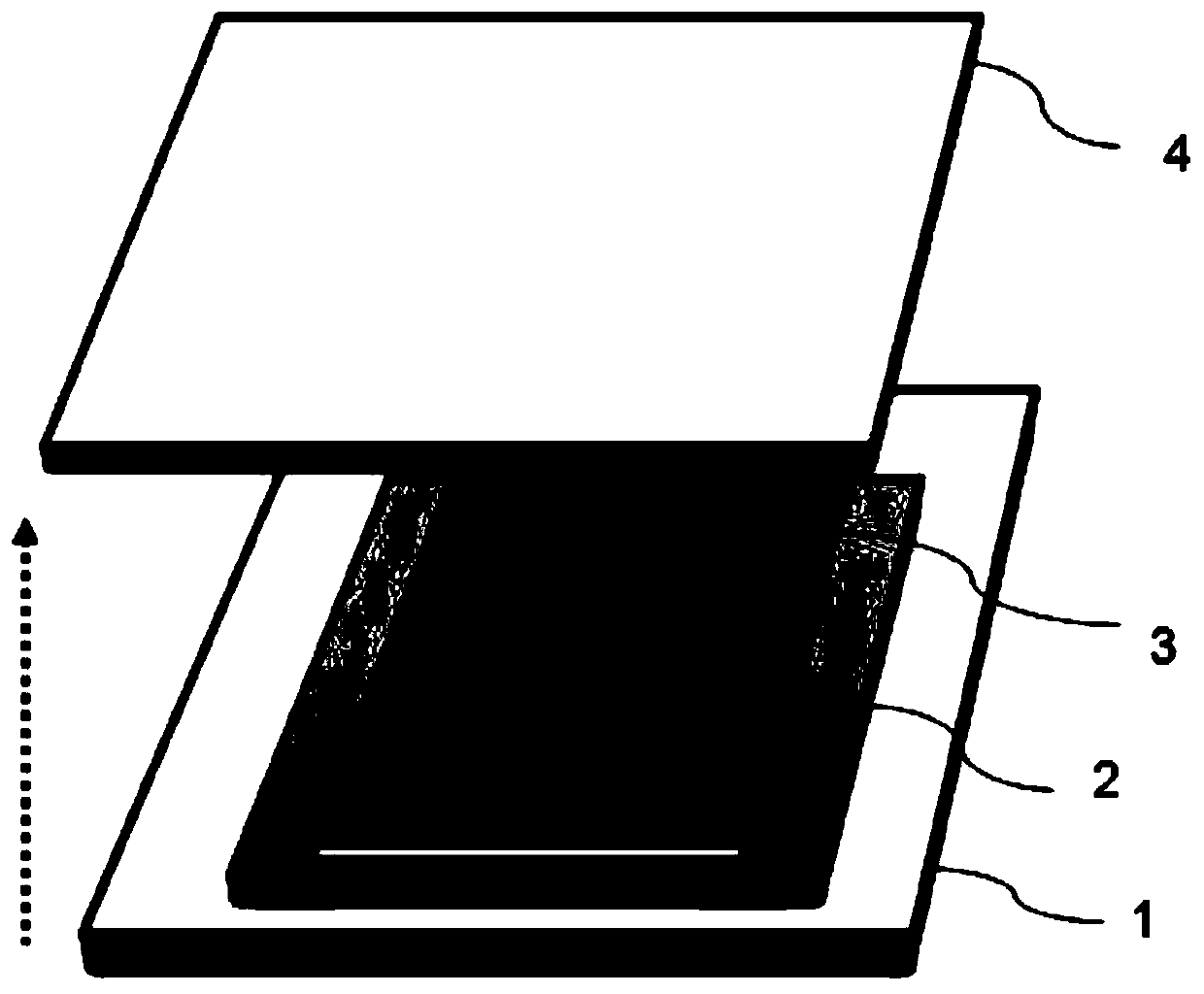

[0059] Those of ordinary skill in the art should be able to understand that one of the characteristics or purposes of the present invention is: the temperature sensor uses a pectin film as a temperature-sensitive material, and xanthan gum is added to improve the flexibility of the film and increase its responsiveness; PDMS is used as a flexible transparent substrate with upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com