Double-layer chip scale package (CSP) light source and manufacturing method thereof

A chip-level packaging and double-layer structure technology, applied in the field of lighting, can solve the problems of exceeding the temperature resistance limit of silica gel, short life, and incomplete colloid, and achieve the effect of solving the problem of color coordinate change, long service life, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

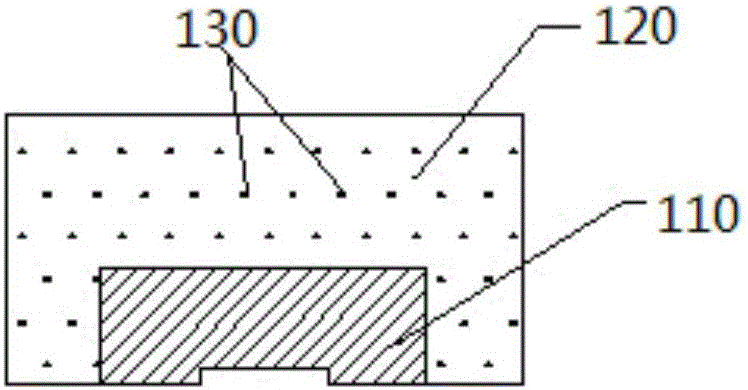

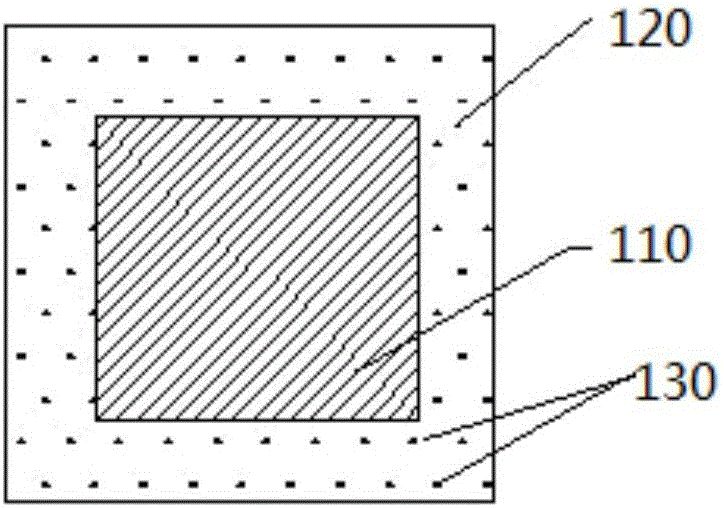

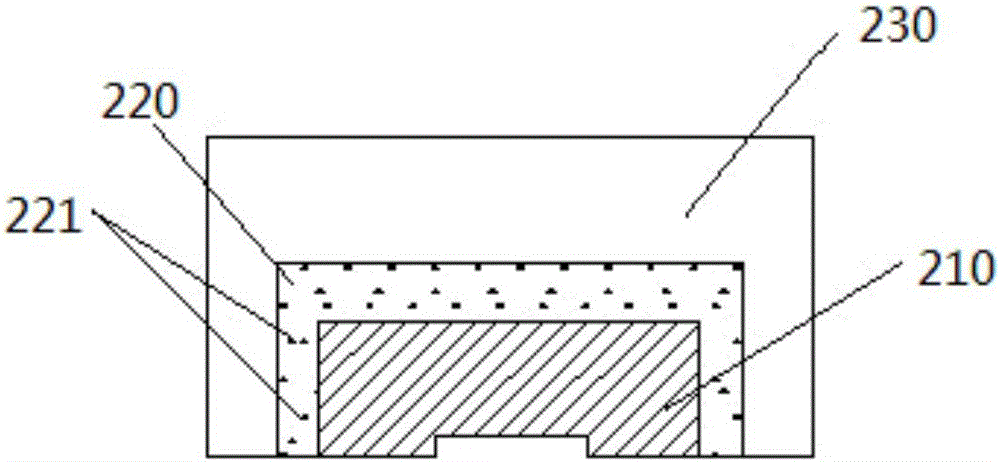

[0028] see Figure 3-5 A light source with a double-layer chip-scale package of the present invention includes a light-emitting chip 210, a fluorescent adhesive layer 220 surrounding the light-emitting chip, and a transparent adhesive layer 230 surrounding the fluorescent adhesive layer.

[0029] The fluorescent adhesive layer 220 in the double-layer structure chip-level packaging light source of the present invention is a thin fluorescent adhesive film, since the phosphor powder is distributed in a very thin adhesive film (the thickness of the thin adhesive film is in the range of 50-150um), and it is close to the light-emitting chip, The heat generated is easily conducted to the substrate through the chip, so its temperature resistance is better. Phosphor powder 221 is uniformly mixed in the fluorescent adhesive layer 220 .

[0030] The transparent adhesive layer 230 is a silica gel layer, and the silica gel at the outermost periphery can protect the fluorescent layer from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com