Composition used for preparing aluminum borosilicate glass, aluminum borosilicate glass, preparation method and application of aluminum borosilicate glass

A kind of technology of aluminoborosilicate and composition, applied in the field of composition for preparing aluminoborosilicate glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

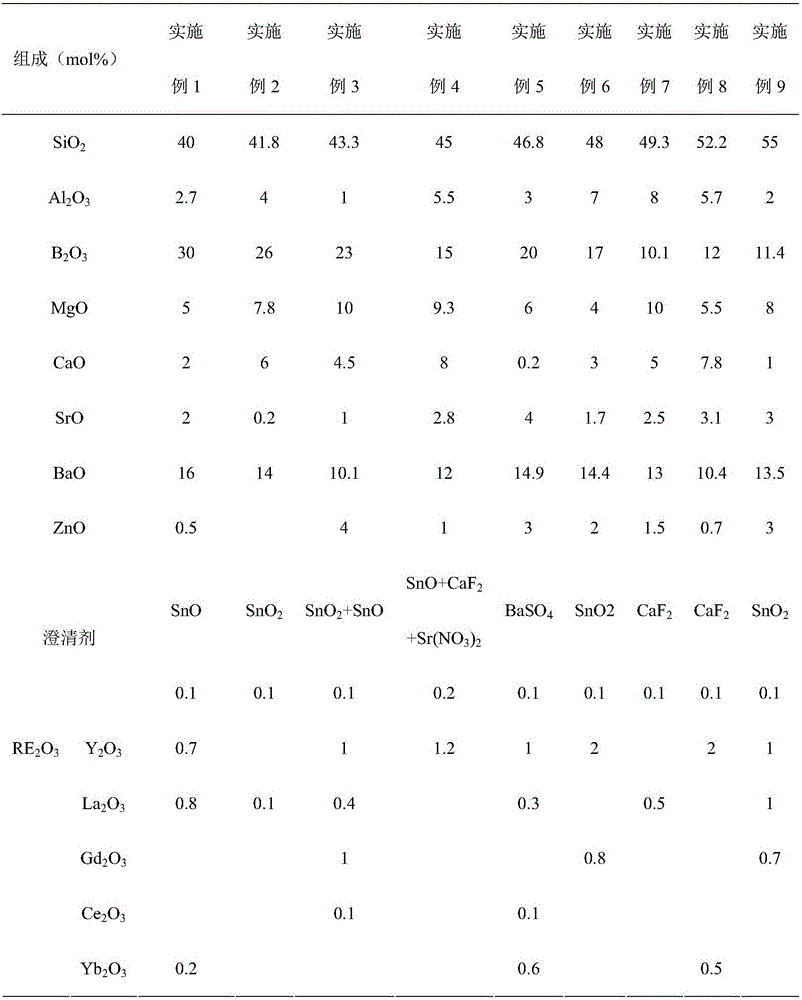

[0044] Table 1 and Table 2 are the composition ratio tables, weigh each component according to Table 1, and mix to obtain 9 groups of compositions (SiO 2 +Al 2 o 32 +Al 2 o 3 >58mol%).

[0045] Table 1 1-9 group composition ratio

[0046]

[0047]

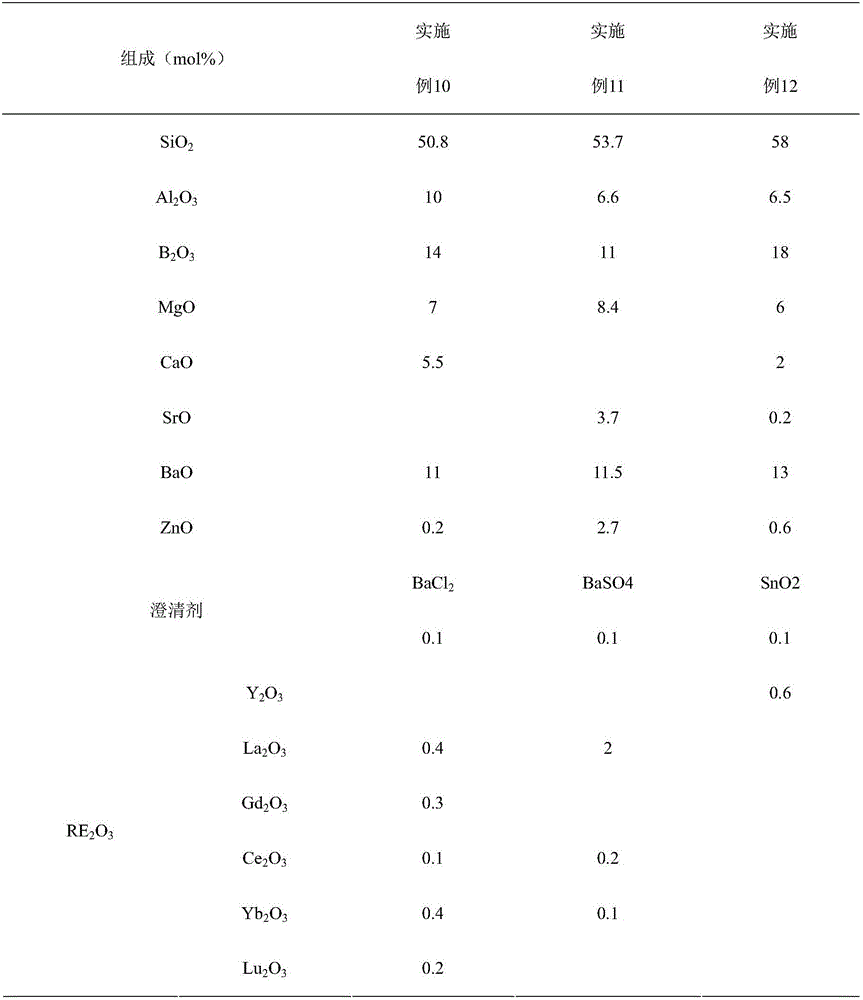

[0048] Table 2 10-12 composition ratio

[0049]

[0050] The obtained 12 groups of composition mixtures were poured into platinum crucibles respectively, and then heated in a resistance furnace at 1350° C. for 4 hours, and stirred with a platinum rod to discharge air bubbles. Pour the molten glass into a stainless steel cast iron mold to form a specified block glass product, then anneal the glass product in an annealing furnace for 2 hours, turn off the power and cool down to 25°C with the furnace. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product. Various properties of each glass product were measured respectively, and the results are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com