A kind of aqueous acrylic pressure-sensitive adhesive emulsion and preparation method thereof

An acrylic pressure-sensitive adhesive, multifunctional acrylic technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of high drying temperature, PE protective film peeling, large workshop space, etc., to reduce drying time. The effect of drying temperature and drying time, avoiding the use of emulsifiers, and reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Another object of the present invention is to provide the preparation method of aqueous acrylic pressure-sensitive adhesive emulsion, described method comprises the following steps:

[0044] 1) Mix 60-80% emulsifier with 70-80% water, stir evenly, then add acrylate monomer and functional monomer, stir evenly to obtain emulsion, set aside;

[0045] 2) Add the remaining 20-30% water and 20-40% emulsifier into the flask, stir and disperse evenly, and when heated to 80-90°C, add the initiator, and drop the emulsion in step 1) Add it to the flask, and the dropping time is 4-5h. After the dropping, heat to 88-95°C and keep it warm for 1-2h, then cool down to 35-45°C, add ammonia water to adjust the pH to 7-8, and add defoamer , stir well, that is.

[0046] In a preferred embodiment, the holding time is 1 h, and the temperature is lowered to 40°C.

Embodiment approach 1

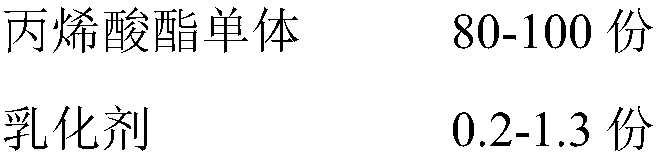

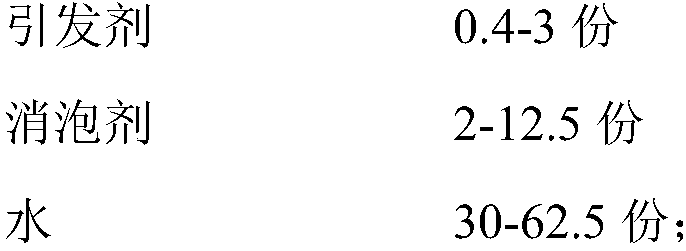

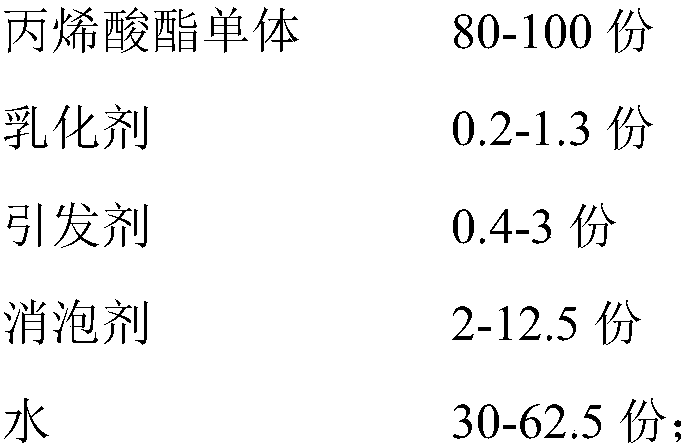

[0048] Embodiment 1, a water-based acrylic pressure-sensitive adhesive emulsion, the acrylic pressure-sensitive adhesive emulsion includes the following components by weight:

[0049]

[0050] Wherein, described emulsifier is the complex emulsifier that anionic emulsifier and nonionic emulsifier are combined, and described anionic emulsifier is carboxylate type emulsifier, phosphate ester type emulsifier, sulfonate type emulsifier One or more, the nonionic emulsifier is EO / PO copolyether.

Embodiment approach 2

[0051] Embodiment 2 is the same as Embodiment 1, except that in the emulsifier, the weight ratio of the anionic emulsifier to the nonionic emulsifier is 0.05-0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com