A kind of heat-sensitive catalyst for solvent-free polyurethane synthesis and preparation method thereof

A heat-sensitive catalyst and solvent-free polyurethane technology, applied in organic chemistry and other fields, can solve problems such as environmental and human hazards, affecting material properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

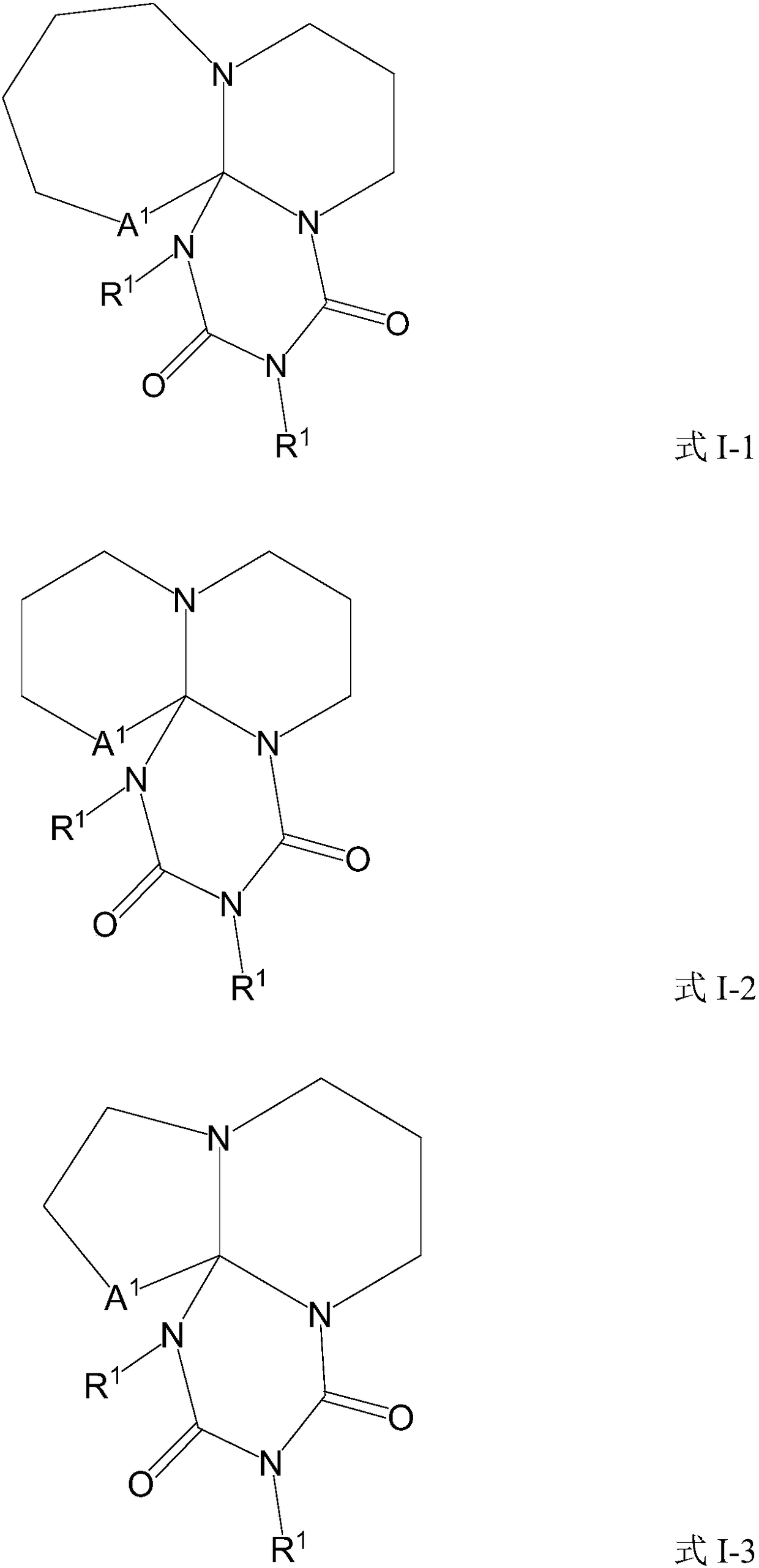

[0084] Preparation of Example 1 Compound 1 Sample A

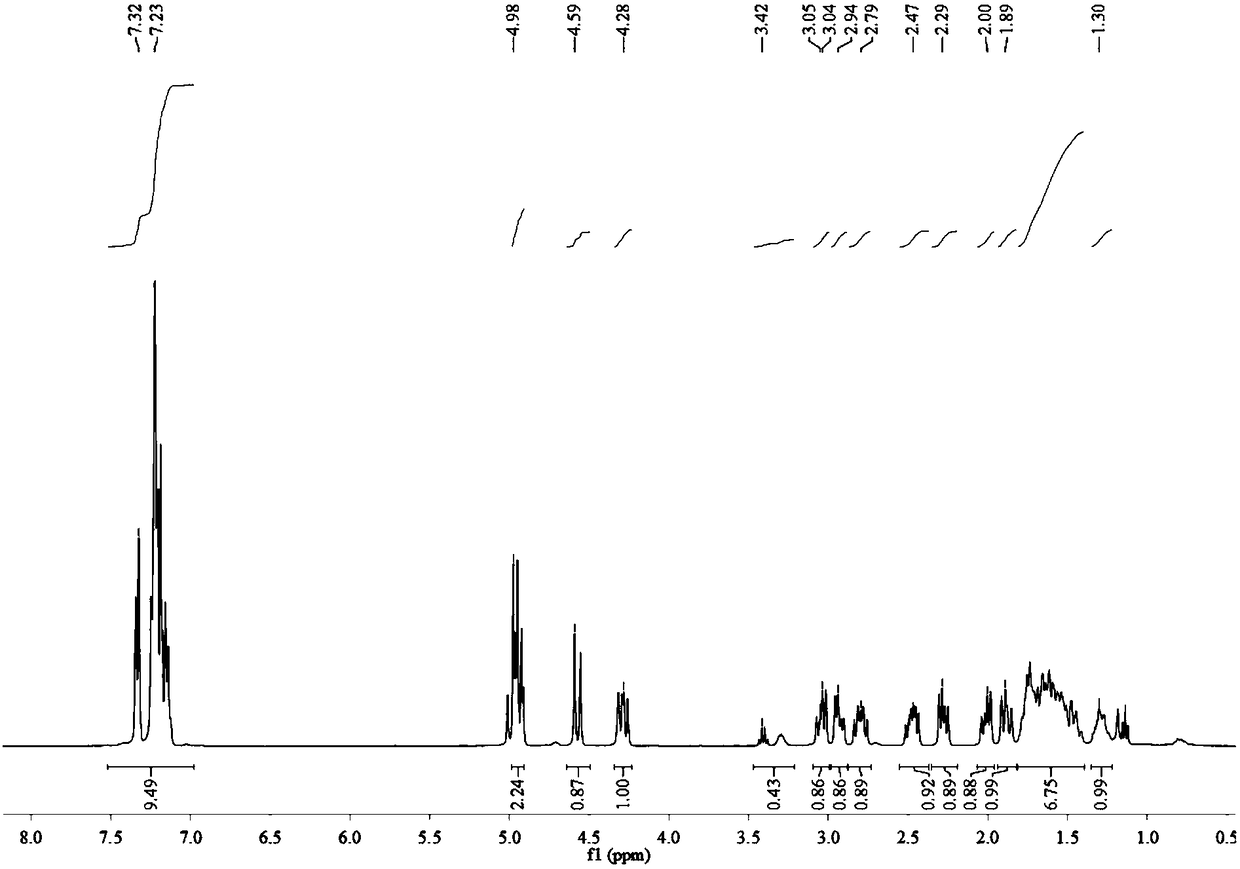

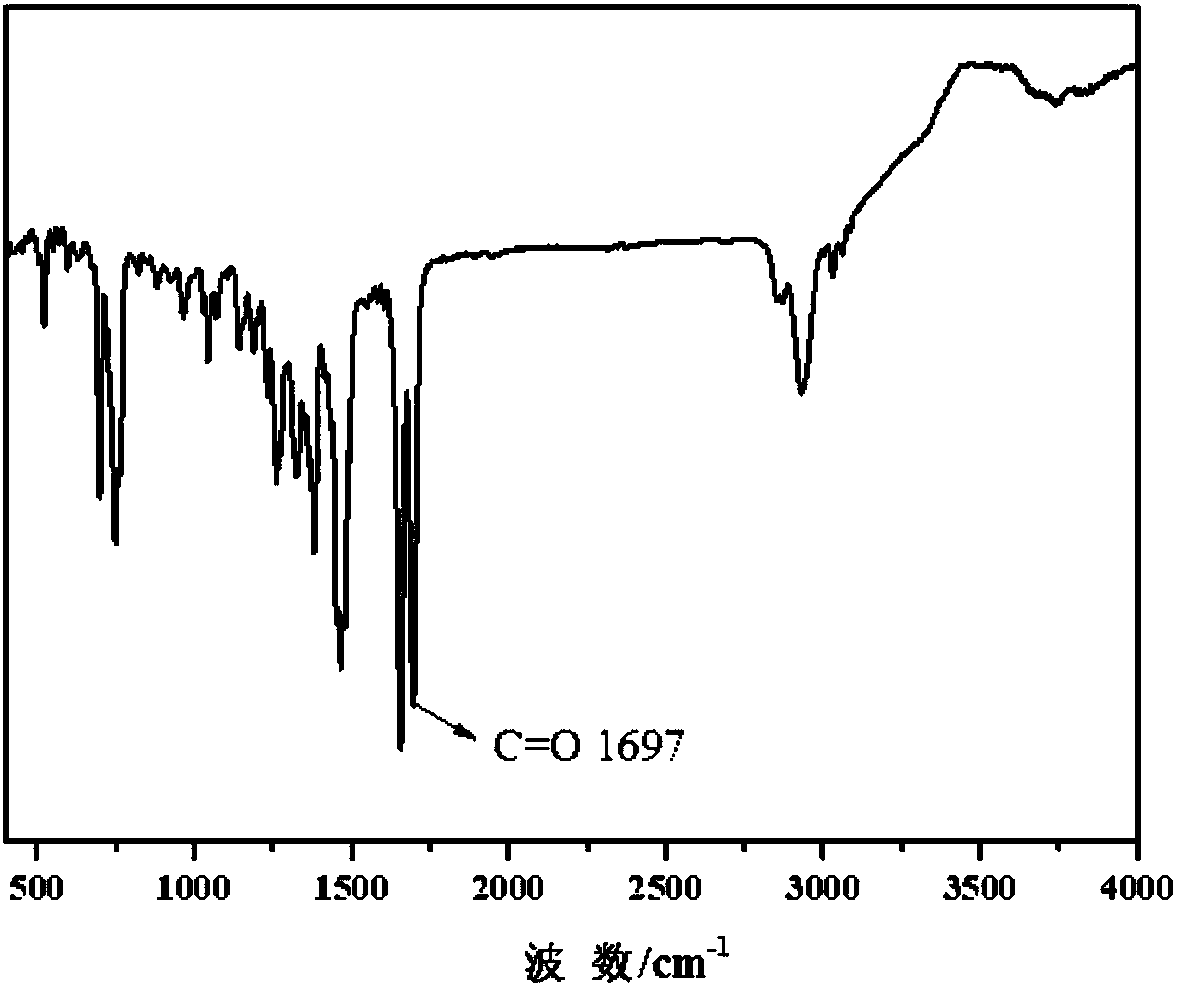

[0085]Add 1.5224g (10mmol) of 1,8-diazabicycloundec-7-ene into a dry single-necked bottle, place it in a low-temperature (-15°C) reaction device, and then add 10ml of anhydrous diethyl ether with a magnetic stirrer Mix and dissolve 1,8-diazabicycloundec-7-ene completely, add 2.6629g (20mmol) of benzyl isocyanate into a 25ml constant pressure dropping funnel, and use constant pressure dropping Slowly add benzyl isocyanate into the above solution through a funnel under magnetic stirring. After the addition is completed, stir rapidly for 5 minutes. After the reaction is completed, a large amount of solids will precipitate out. The recrystallized solid was filtered, then washed 2-3 times with frozen ether, and then dried under vacuum at 90°C for 4-5 hours. The obtained product was Compound 1, which was recorded as sample A, and the obtained product was placed in a dry sealed system Store in a dry environment until use.

[008...

Embodiment 2

[0088] Preparation of Example 2 Compound 1 Sample B

[0089] Add 1.2418g (10mmol) of 1,5-diazabicyclo[4,3,0]nonene-5 to a dry one-necked bottle, place it in a low-temperature (-10°C) reaction device, and then add 10ml of Mix and dissolve 1,5-diazabicyclo[4,3,0]nonene-5 with water and ether magnetically, add 2.5298g (19mmol) of benzyl isocyanate to a 25ml constant pressure dropping funnel Among them, use a constant pressure dropping funnel to slowly add benzyl isocyanate into the above solution under magnetic stirring, and stir rapidly for 10 minutes after the addition is completed. After the reaction is completed, a large amount of solids will precipitate out. Recrystallize in a low-temperature device, filter the recrystallized solid, wash with frozen ether 2 to 3 times, and then dry at 90°C under vacuum for 4 to 5 hours. The obtained product is compound 1, which is designated as sample B. The obtained product is packed into a dry sealed system and stored in a dry environment...

Embodiment 3

[0090] Preparation of Example 3 Compound 1 Sample C

[0091] Add 1.5322g (10mmol) of 7-methyl-1,5,7-triazabicyclo[4.4.0]dec-5-ene into a dry one-necked bottle, and place it in a low temperature (0°C) reaction device , then add 10ml of anhydrous ether and magnetically stir to make 7-methyl-1,5,7-triazabicyclo[4.4.0]dec-5-ene mixed and dissolved completely, and 2.6629g (19mmol) of isocyanide Add benzyl isocyanate into a 25ml constant-pressure dropping funnel, slowly add benzyl isocyanate into the above solution under magnetic stirring using the constant-pressure dropping funnel, and stir rapidly for 15 minutes after the addition is completed. After the reaction is completed, there will be a large amount of The solid precipitated, put the reaction bottle into a low-temperature device at -30°C for recrystallization, filtered the recrystallized solid, washed it with frozen ether for 2 to 3 times, and then dried it under vacuum at 90°C for 4 to 5 hours to obtain the product That is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com