Multi-element solid solution strengthening heat-resistant titanium alloy

A solid solution strengthening and titanium alloy technology, applied in the field of titanium alloy materials, can solve the problems of unsatisfactory alloy thermal strength, high manufacturing cost, and poor processing performance, so as to ensure high temperature creep performance, reduce adverse effects, and improve processing plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

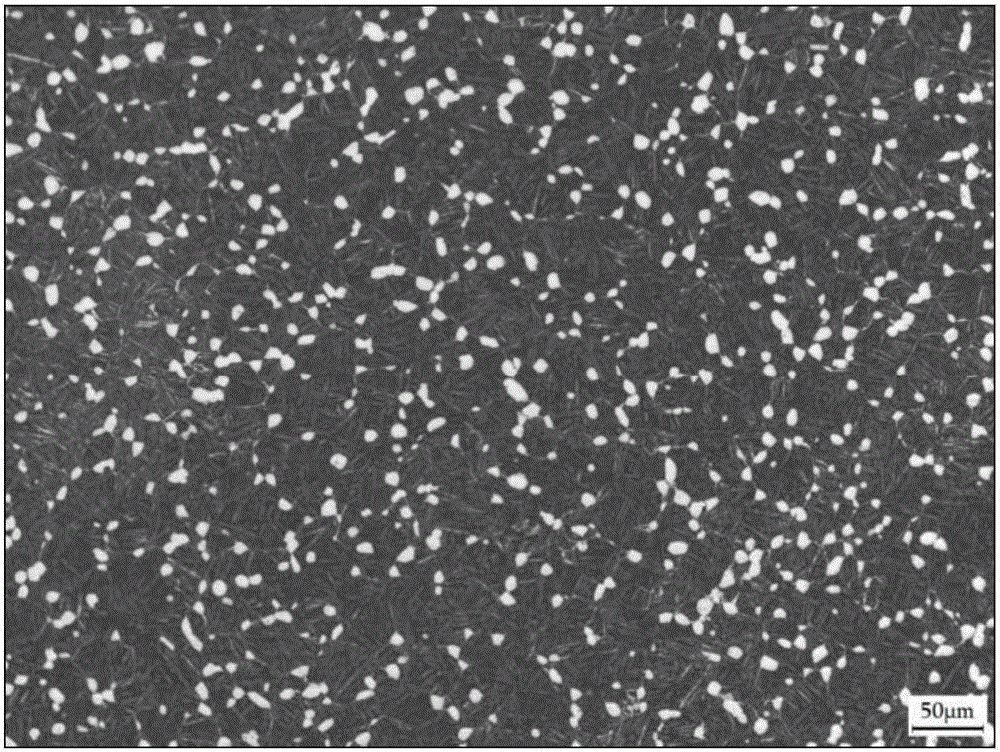

Embodiment 1

[0025] The multi-component solid-solution strengthened heat-resistant titanium alloy in this embodiment is composed of the following components in mass percentage: Al: 6%, Sn: 3%, Zr: 4%, Nb: 0.5%, Mo: 0.5%, W: 1.5 %, Ta: 1.5%, Si: 0.35%, C: 0.05%, and the balance is Ti and unavoidable impurities.

[0026] The preparation method of multi-component solid-solution strengthened heat-resistant titanium alloy in this example is: 0-grade sponge titanium, aluminum bean, Ti-Sn master alloy, sponge zirconium, Al-Nb master alloy, Al-Mo master alloy, Al-Si master alloy And Ti-C intermediate alloy, according to the design composition, the raw materials except sponge titanium are packaged into an alloy package, and pressed together with the sponge titanium to obtain an electrode, and the electrode is prepared by vacuum consumable arc melting to obtain an alloy ingot, and the alloy ingot is peeled off the surface After the riser and tail end are cut off, billet forging, high-temperature β-p...

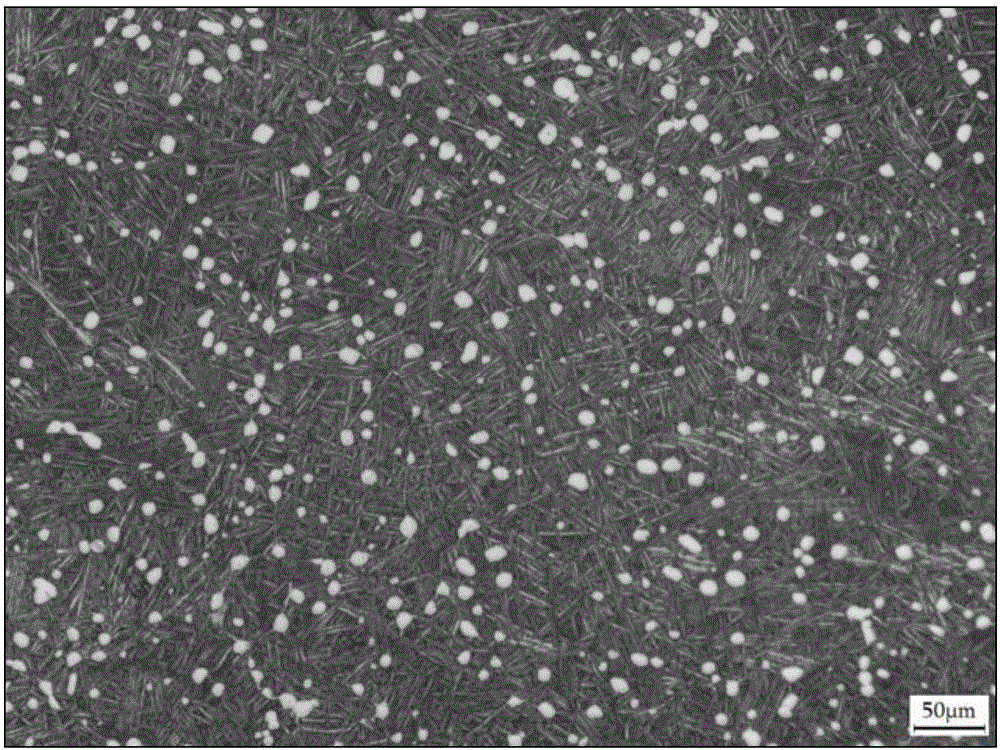

Embodiment 2

[0030] The multi-component solid-solution strengthened heat-resistant titanium alloy in this embodiment is composed of the following components in mass percentage: Al: 5.5%, Sn: 2.5%, Zr: 3.0%, Nb: 0.3%, Mo: 0.3%, W: 1.0 %, Ta: 1.0%, Si: 0.25%, C: 0.03%, and the balance is Ti and unavoidable impurities.

[0031] The preparation method of multi-component solid-solution strengthened heat-resistant titanium alloy in this example is: 0-grade sponge titanium, aluminum bean, Ti-Sn master alloy, sponge zirconium, Al-Nb master alloy, Al-Mo master alloy, Al-Si master alloy And Ti-C intermediate alloy, according to the design composition, the raw materials except sponge titanium are packaged into an alloy package, and pressed together with the sponge titanium to obtain an electrode, and the electrode is prepared by vacuum consumable arc melting to obtain an alloy ingot, and the alloy ingot is peeled off the surface After the riser and tail end are cut off, billet forging, high-temperatu...

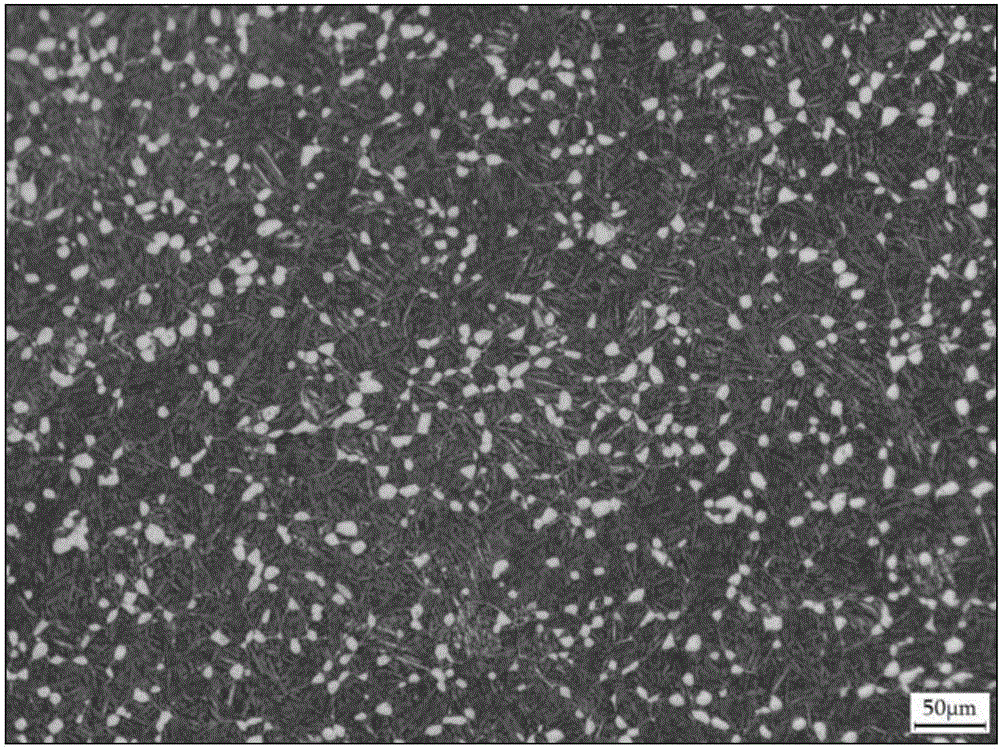

Embodiment 3

[0035] The multi-component solid-solution strengthened heat-resistant titanium alloy in this embodiment is composed of the following components in mass percentage: Al: 6.5%, Sn: 3.5%, Zr: 5.0%, Nb: 0.7%, Mo: 0.7%, W: 2.0 %, Ta: 2.0%, Si: 0.45%, C: 0.07%, and the balance is Ti and unavoidable impurities.

[0036] The preparation method of multi-component solid-solution strengthened heat-resistant titanium alloy in this example is: 0-grade sponge titanium, aluminum bean, Ti-Sn master alloy, sponge zirconium, Al-Nb master alloy, Al-Mo master alloy, Al-Si master alloy And Ti-C intermediate alloy, according to the design composition, the raw materials except sponge titanium are packaged into an alloy package, and pressed together with the sponge titanium to obtain an electrode, and the electrode is prepared by vacuum consumable arc melting to obtain an alloy ingot, and the alloy ingot is peeled off the surface After the riser and tail end are cut off, billet forging, high-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com