Continuous electrolytic polishing equipment

An electrolytic polishing and equipment technology, applied in the electrolytic process, electrolytic components, etc., can solve the problems of unsatisfactory electrolytic effect in continuous operation, complicated production and processing process, and low product quality pass rate, so as to eliminate burrs and gaps and increase strength , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

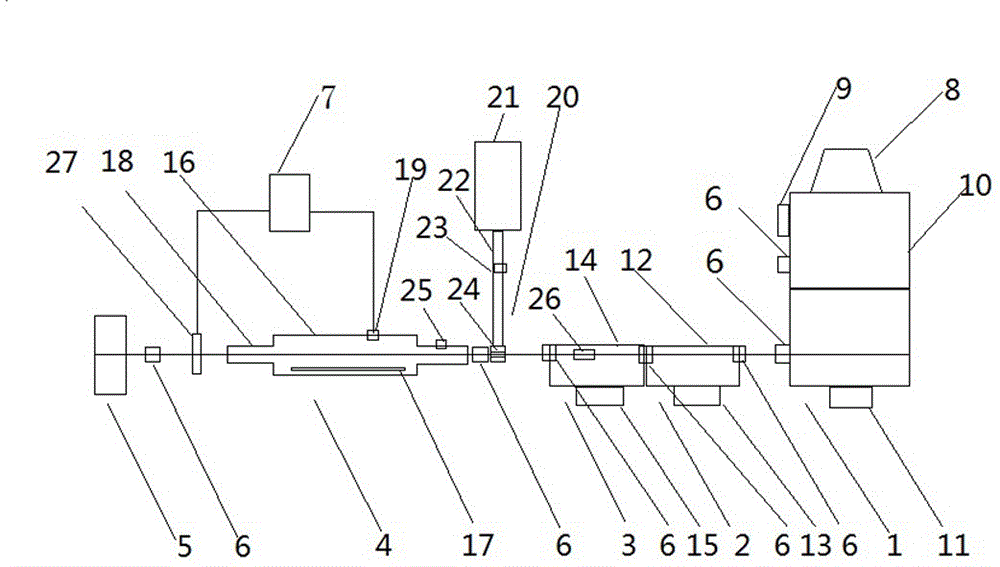

[0019] like figure 1 As shown, a continuous electrolytic polishing equipment includes an electrolysis device 1, a neutralization device 2, a water washing device 3, a dehydration device 19, an annealing device 4, a take-up device 5 and an instrument control cabinet 7, an electrolysis device 1, a neutralization device 2 , washing device 3, dehydration device 19, annealing device 4 and take-up device 5 are placed in order. The electrolysis device 1 comprises an exhaust system 8, a tape release device 9, an electrolyzer 10 and an electrolyte circulation pump 11, the electrolyzer 10 is two electrolyzers arranged up and down, the exhaust system 8 is located at the top of the electrolyzer 10, and the tape release device 9 is a torque motor belt release device, which is arranged outside the electrolytic cell 10, and the electrolyte circulation pump 11 is arranged at the bottom of the electrolytic cell 10; the neutralization device 2 includes a neutralization tank 12 and a neutralizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com