Wall brick building machine

A brick machine and wall-laying technology, which is applied in construction, building structure, and building material processing, can solve personal safety problems, reduce personal safety risks, reduce labor, and solve the shortage of construction labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

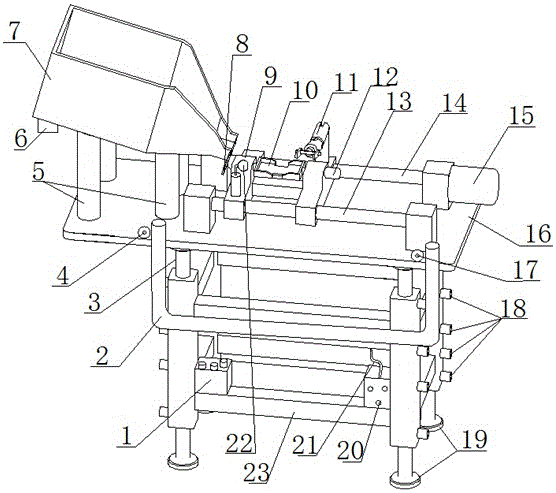

[0017] Now do further detailed explanation in conjunction with accompanying drawing.

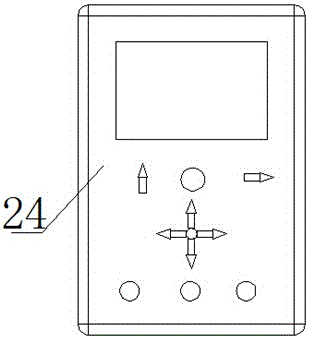

[0018] Such as figure 1 , figure 2 As shown, a wall brick machine includes: hydraulic station 1, U-shaped pipe 2, upper telescopic hydraulic rod 3, camera ① 4, spring column 5, vibration motor 6, funnel 7, valve 8, trolley 9, turning plate 10, Manipulator 11, motor 12, polished rod 13, screw rod 14, stepper motor 15, top plate 16, camera 17. Hydraulic pipe interface 18, lower telescopic hydraulic rod 19, control electric box 20, wireless transceiver 21, camera 22, frame 23, remote controller 24.

[0019] The main working principle of a wall-laying brick machine: first place the wall-laying machine at the place where wall-laying bricks are needed, after placing it, adjust it through the upper telescopic hydraulic rod 3 and the lower telescopic hydraulic rod 19 of the frame The horizontal position of the fuselage and top plate 16. Then put a certain amount of bricks in the funnel 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com