A Tunnel Assembled Primary Support Method

An initial support and assembled technology, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., to achieve the effects of wide application range, guaranteed construction quality, and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

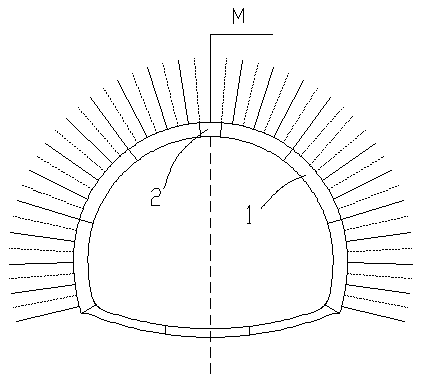

[0035] Embodiment one, such as figure 1 As shown, for small-section tunnels, integral support is adopted, that is, one-time excavation and one-time support forming. M in the figure is the surrounding rock around the tunnel, the same below, and the specific method is:

[0036] 1. Measurement and stakeout: measure the excavation contour line according to the design section.

[0037] 2. Excavation: Weak surrounding rocks shall be excavated by excavators, and relatively hard surrounding rocks shall be excavated by loose blasting. The excavation at one time is preferably 50-80cm.

[0038] 3. Excavating ballast, cleaning and leveling the excavation surface.

[0039]4. Assemble the support components according to the diagram, including 9 common support components 1 and 1 adjustment block 2 on the top. All the support components are connected by bolts to form a whole.

[0040] 5. Back grouting filling.

[0041] 6. Remove the temporary support.

Embodiment 2

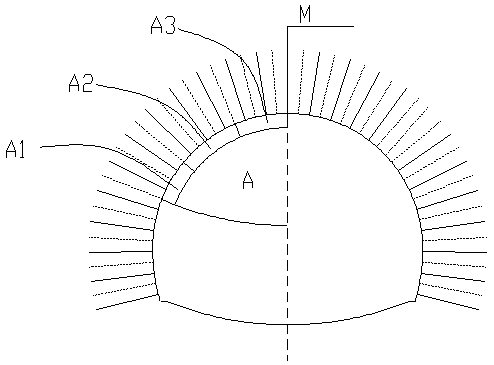

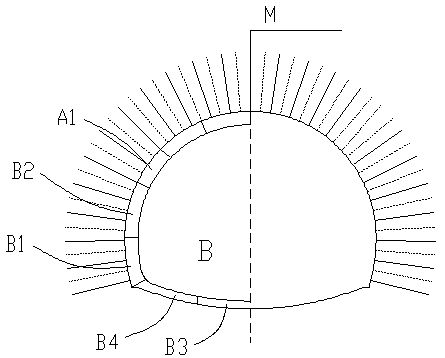

[0042] Embodiment 2, for a large section, partial excavation support is adopted, that is, the partial excavation is respectively formed into a ring, and the overall connection is carried out according to the following steps, with the centerline of the tunnel section width as the Y axis and the midpoint of the tunnel height as the origin, The horizontal line is the X-axis, and the rectangular coordinates of the plane are set:

[0043] 1. Excavate area A of the second quadrant, such as figure 2 As shown, carry out initial support and use channel steel, screw steel and other profiles or synthetic support rods for temporary locking. The specific methods are:

[0044] ① Measurement and stakeout: measure the excavation contour line according to the design section.

[0045] ②Excavation: The weak surrounding rock shall be excavated by an excavator, and the relatively hard surrounding rock shall be excavated by loosening blasting, with a excavation length of 60cm.

[0046] ③Ballasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com