Self-powered oil and gas pipeline monitoring device

A technology for oil and gas pipelines and monitoring devices, applied in electrical components, pipeline systems, generators/motors, etc., can solve the problems of electromagnetic interference, unsuitable pipelines, and high cost of power generation devices, and achieve uniform stress distribution, controllable deformation, and diameter. small-scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

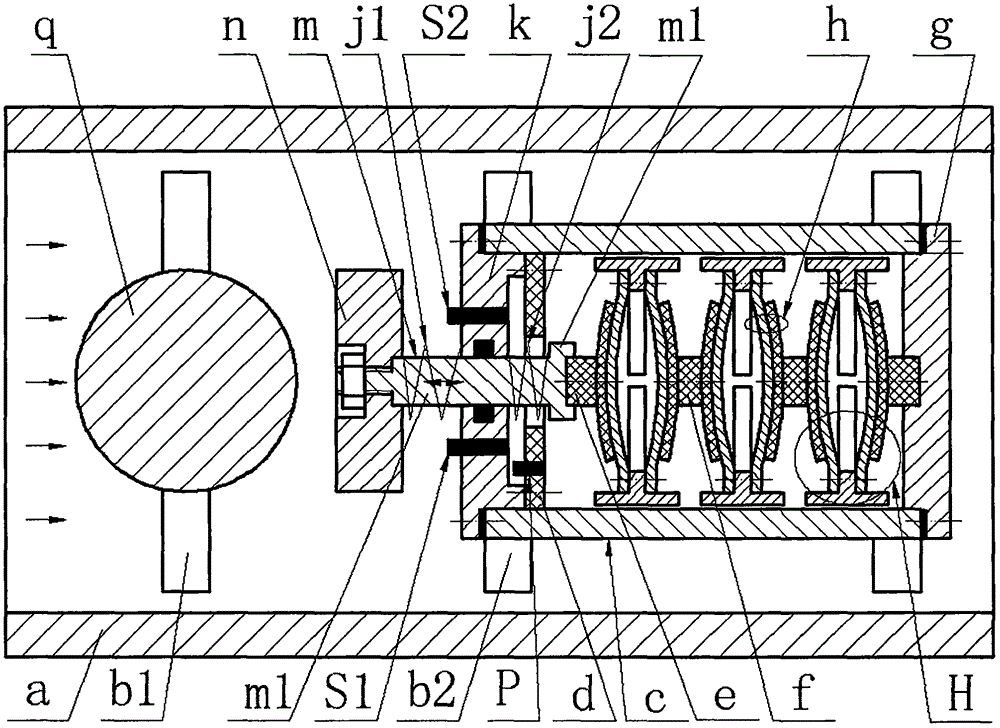

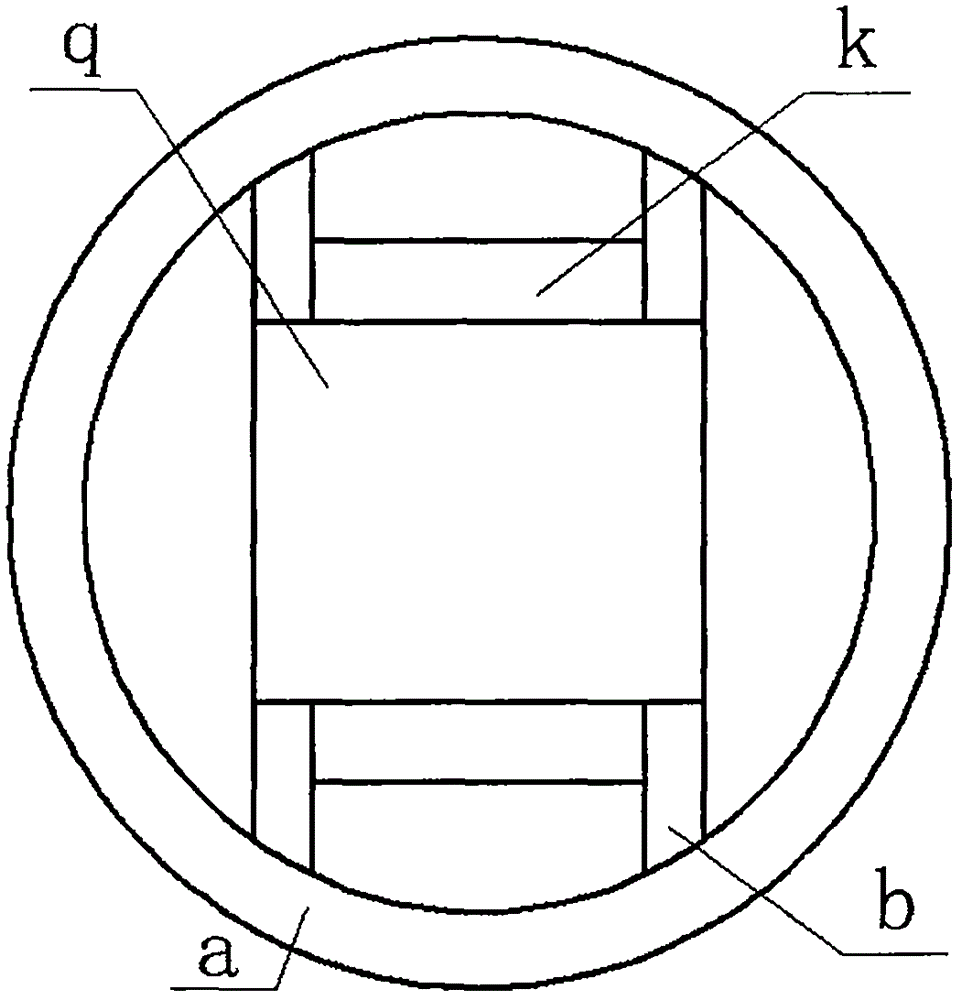

[0014] On the inner wall of the pipe a, a cylindrical spoiler q is installed through the first rib b1, and an inner cylinder c is installed through the second rib b2. The center of the spoiler q is perpendicular to the center of the inner cylinder c, and the left and right ends of the inner cylinder c The left end cover k and the right end cover g are respectively installed with screws; the temperature sensor S1 and the pressure sensor S2 are inlaid on the left end cover k, and the side of the left end cover k close to the inner cylinder c is installed with a circuit board d with a transmitting unit P through screws. The left semi-axis m1 of the stepped shaft m protrudes from the inner cylinder c through the center hole of the left end cover k, and the end of the left semi-axis m1 is equipped with an actuator n; the left semi-axis m1 is covered with a balance spring j1 and a limit spring j2 , the left and right ends of the balance spring j1 lean against the exciter n and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com