A system for reducing the cold junction temperature of thermoelectric devices using enhanced dielectric nanofluids

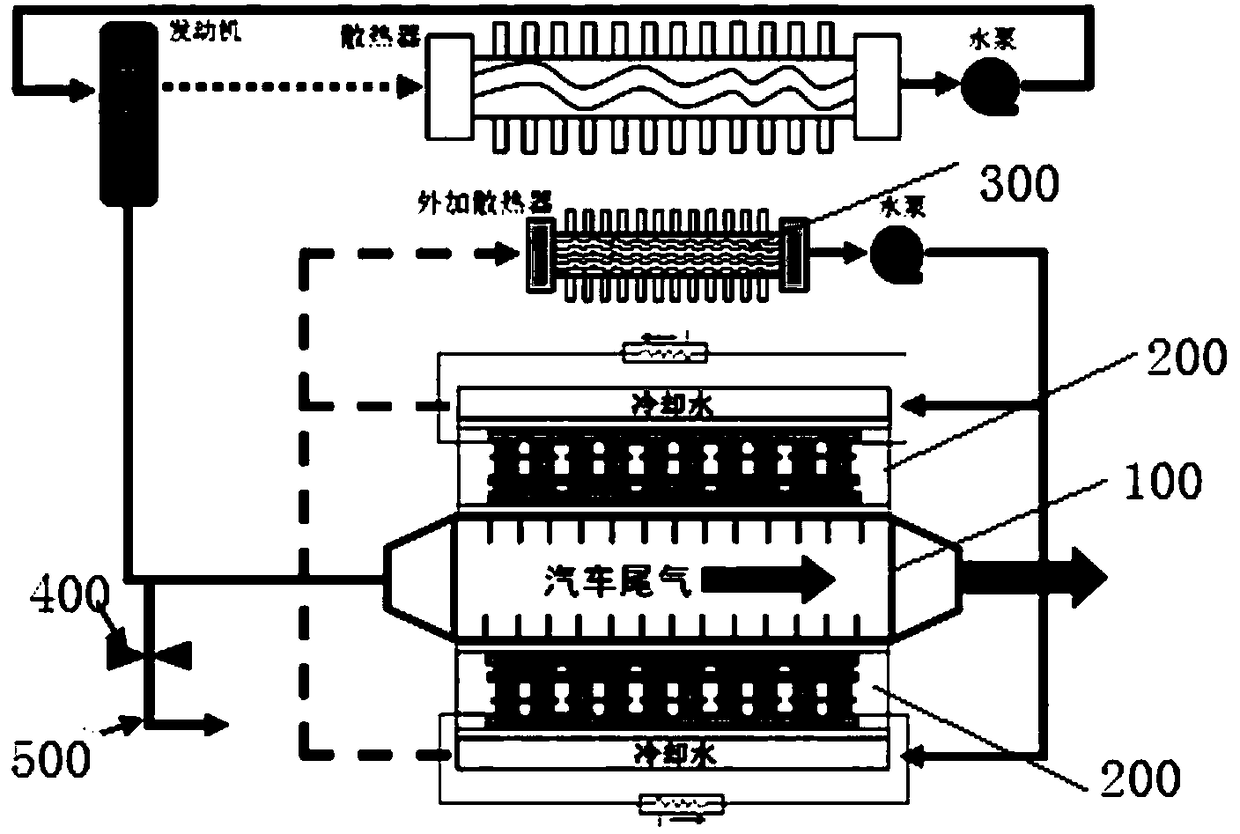

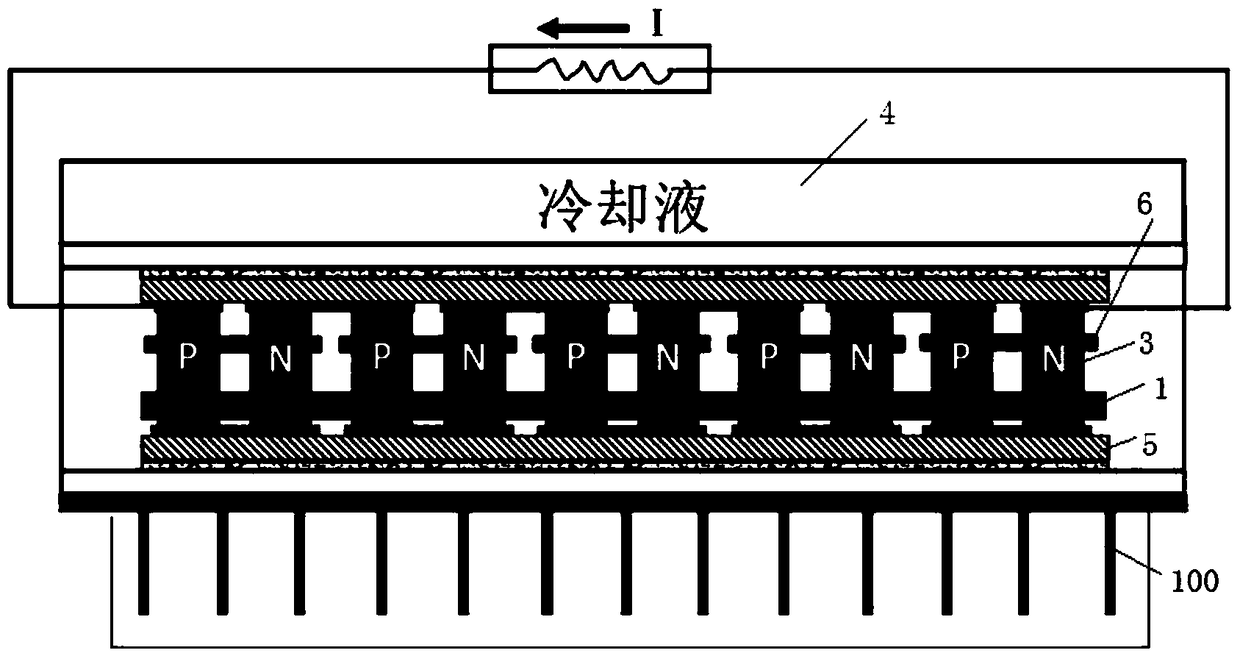

A technology of thermoelectric devices and nanofluids, which is applied in the direction of thermoelectric devices that only use the Peltier or Seebeck effect, can solve the problems of inability to dissipate heat at the cold end and increase the load of the engine, and achieve enhanced heat dissipation at the cold end, reduced temperature at the cold end, and improved conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

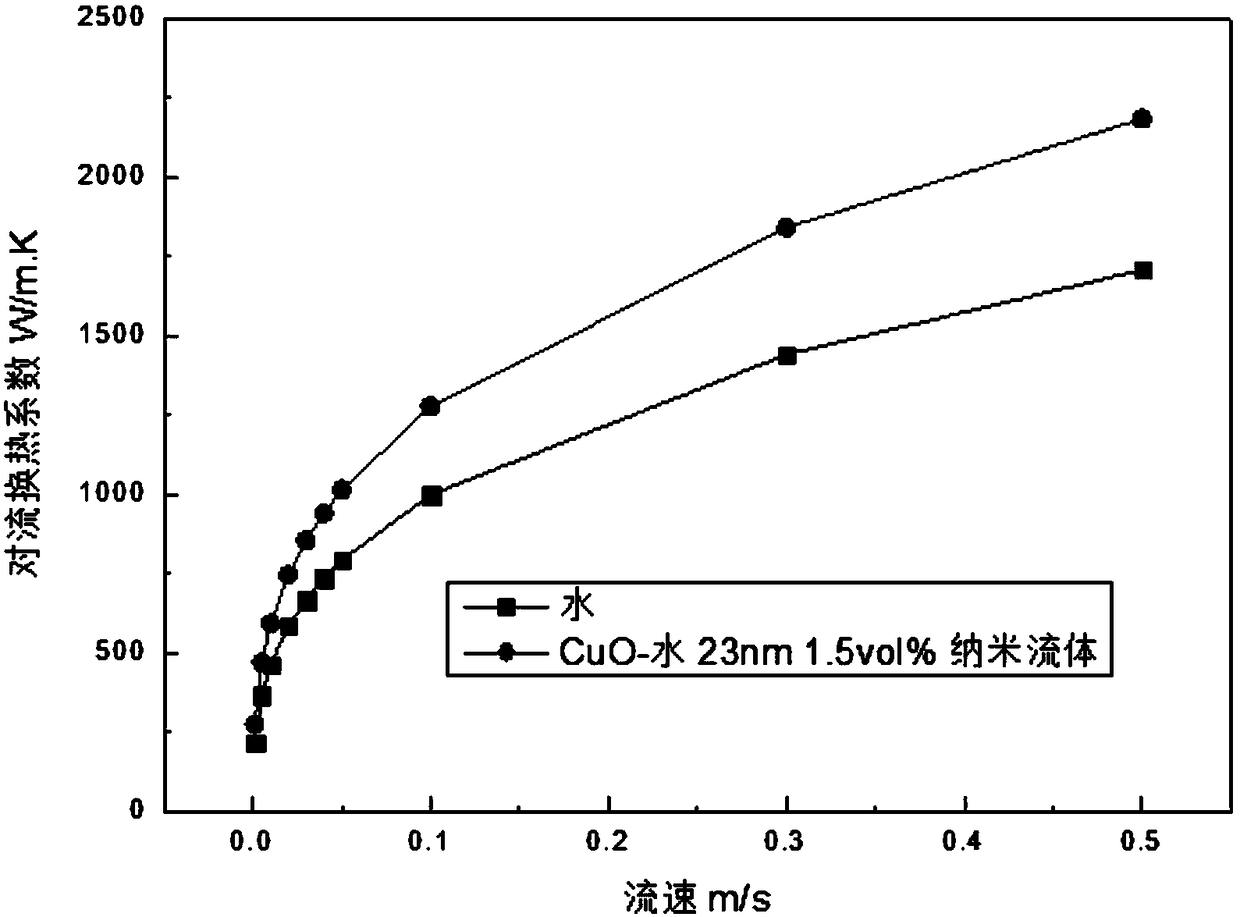

[0037] Water and CuO-water nanofluid are used as the cooling fluid at the cold end, the inlet temperature of the cooling fluid is set at 22°C, and the equivalent diameter of the fluid is 10mm×10mm. Depend on figure 2 The heat transfer coefficient of coolant at different flow rates shows that at the same flow rate, nanofluid, as a new type of heat transfer medium to improve the heat transfer performance of the fluid, also has a greater strengthening effect on the convective heat transfer coefficient of the fluid interface. When the flow rate is 0.5m / s, the convective heat transfer coefficient is 1707W / m.K when water is used as the cooling liquid, and increases to 2182W / m.K when nanofluid is used. The output data of the TEG system when nanofluid and water are used as cooling fluid respectively. Such as image 3 As shown, nanofluid tends to have a better output potential difference at the flow rate of 0.001 to 0.5m / s due to the enhanced heat transfer effect of nanofluid. The ...

Embodiment 2

[0039] Water and carbon nanotube-water nanofluid are used as the cooling fluid at the cold end, the inlet temperature of the cooling fluid is set at 22°C, and the equivalent diameter of the fluid is 10mm×10mm. Due to the dependence of the power and efficiency of the TEG system on the temperature of the thermoelectric power generation device, when the flow rate of the coolant water increases from 0.001 to 0.05m / s, the output power increases from 0.647 to 1.68. At the same time, the efficiency of thermoelectric power generation system increased from 0.0792 to 0.129. When the temperature of the hot end of the thermoelectric power generation system is fixed, the flow rate of the coolant at the cold end is an important factor affecting the output power and system efficiency of the TEG system. Such as Figure 4 As shown, the enhanced heat transfer effect of the nanofluid increases the output power of the TEG system by 22.7% and the system efficiency by 11% when the speed is 0.001m / ...

Embodiment 3

[0041] The thermal interface material prepared by nano-copper and epoxy resin is used as the heat exchange medium between the thermoelectric device and the heat exchanger, and the thermal conductivity of the nano-copper / epoxy resin thermal interface material is 1W when the mass fraction of nano-copper particles is 70wt%. / mk or so. When the interface contact pressure between the thermoelectric device and the heat exchanger is 1MPa, and no thermal interface material is added, the contact thermal resistance between the thermoelectric device and the heat exchanger is 330mm 2 K / W, and after adding 70wt% nano-copper / epoxy resin thermal interface material, the contact thermal resistance is reduced to 20mm 2 About K / W, which greatly reduces the contact thermal resistance between the two and improves the heat transfer performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com