Crystal oscillator and production method thereof

A crystal oscillator and chip technology, which is applied in the electronic field, can solve the problems of mobile phone timing disorder, chip conductive upper cover collision and short circuit, etc., and achieve the effect of preventing mobile phone timing disorder, preventing short circuit to ground, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

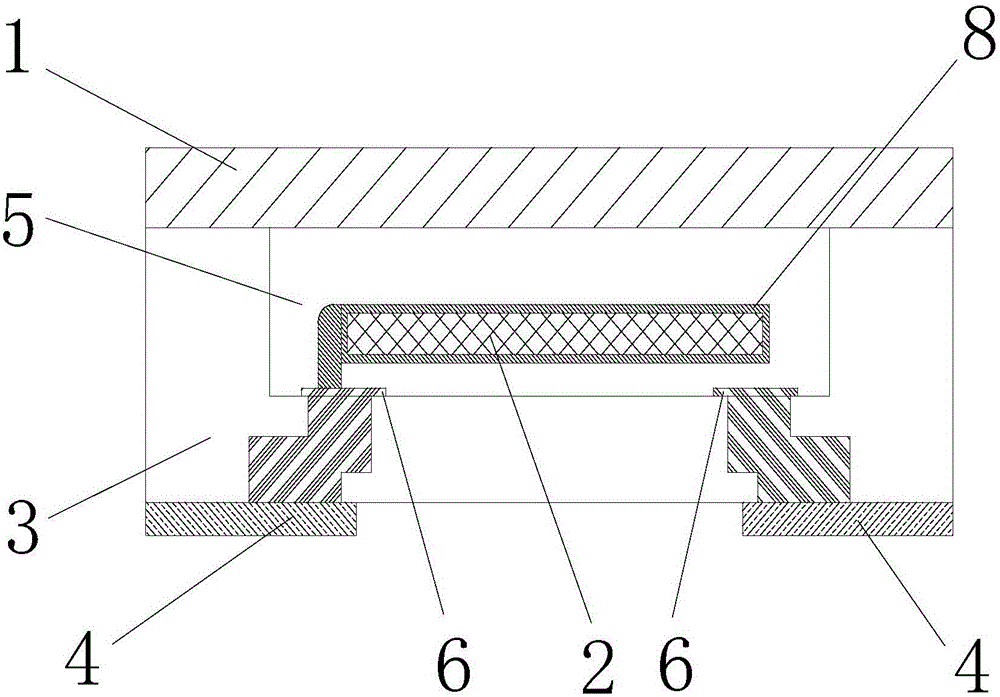

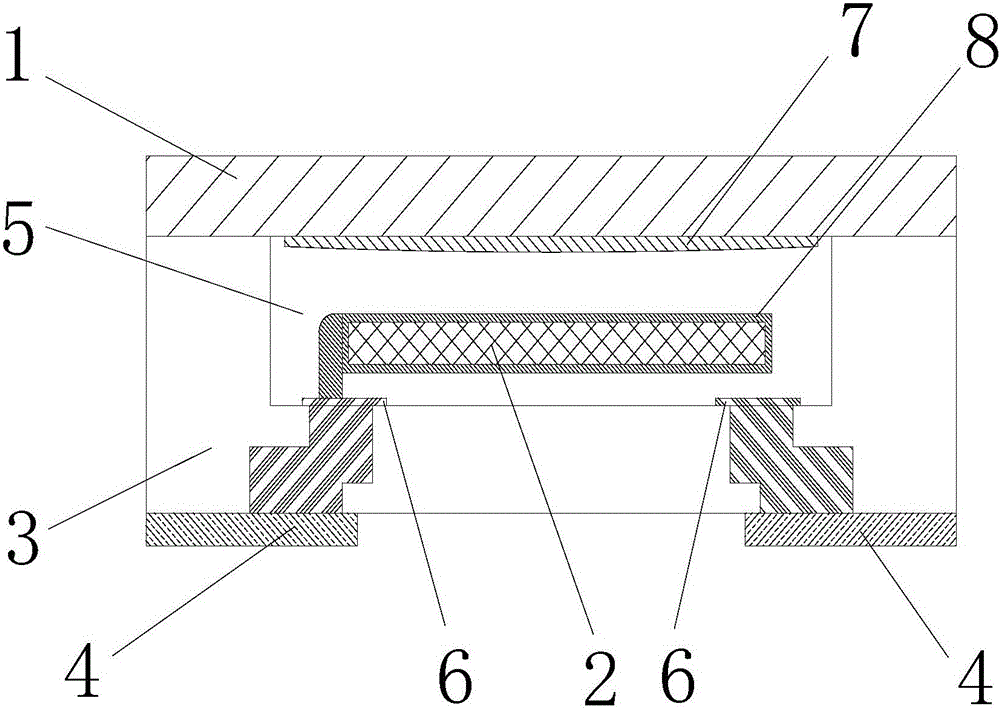

[0035] figure 2 It is a schematic diagram of the structure of a crystal oscillator provided by an embodiment of the present invention, such as figure 2 As shown, a crystal oscillator provided by the present invention includes a base 3, a conductive upper cover provided on the top of the base 3, a chip 2 provided in the base 3, and two pads 4 provided at the bottom of the base 3 The base 3 is provided with an accommodation cavity 5 under the conductive upper cover 1, two connection solder joints 6 are provided at the bottom of the accommodation cavity 5 to be connected to the pad 4 correspondingly, and the chip 2 is provided in the accommodation In the cavity 5, an electrode 8 is provided on the surface of the chip 2 to be connected to one of the connection solder joints 6, wherein the bottom surface of the conductive upper cover 1 is provided with a preset position 7 above the chip 2. An insulating layer is provided on it. The insulating layer at the preset position 7 insulat...

Embodiment 2

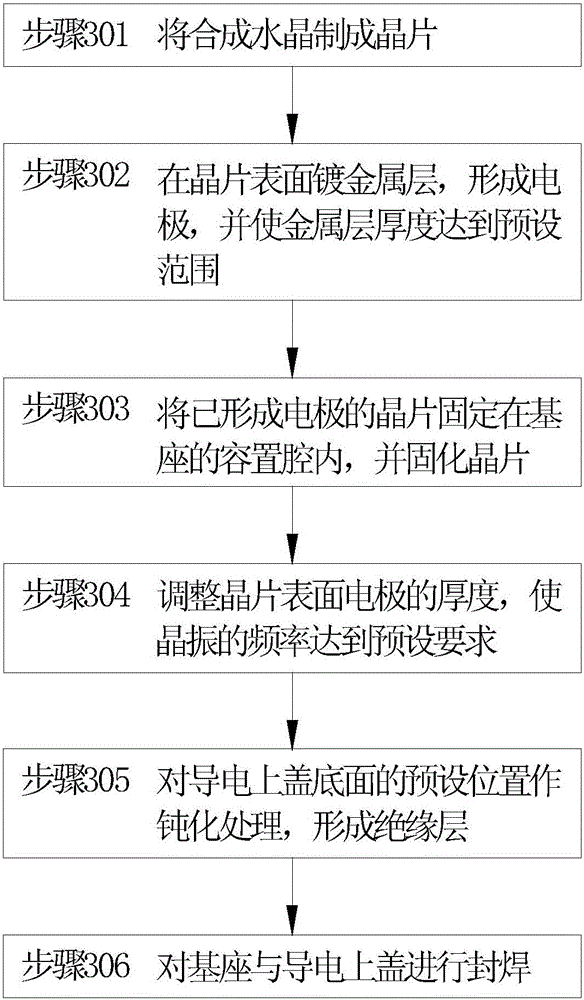

[0038] image 3 Is a schematic flow chart of a crystal oscillator manufacturing method provided by an embodiment of the present invention; Figure 4 It is a schematic flow diagram of the step of forming a synthetic crystal into a wafer in the crystal oscillator manufacturing method provided by an embodiment of the present invention.

[0039] Such as figure 2 As shown, the method for manufacturing a crystal oscillator provided by the present invention includes:

[0040] Step 301: The synthetic crystal is made into a chip 2;

[0041] In step 302, a metal layer is plated on the surface of the wafer 2 to form an electrode 8 and the thickness of the metal layer reaches a preset range;

[0042] Step 303: Fix the wafer 2 with the electrode 8 formed in the accommodating cavity 5 of the base 3, and solidify the wafer 2;

[0043] Step 304 adjust the thickness of the electrode 8 on the surface of the wafer 2 so that the frequency of the crystal oscillator meets the preset requirement;

[0044] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com