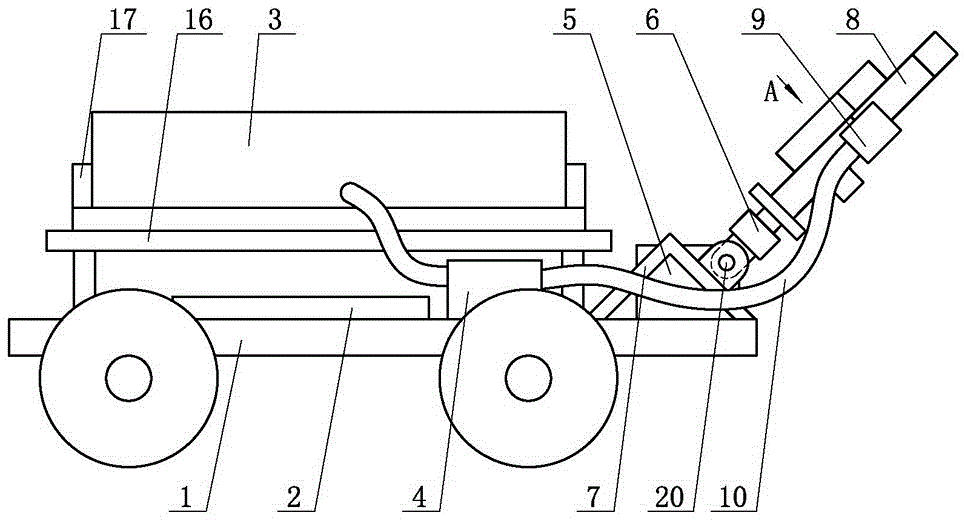

Weeding and weeding robot in the fence of electric equipment

A technology for power equipment and robots, applied in the field of robots, can solve the problems of inability to carry out foreign body cleaning and weed removal, high-voltage equipment short-circuit to the ground, easy to be corroded, etc., to achieve good insulation performance, avoid short-circuit to ground, insulation performance high-level effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

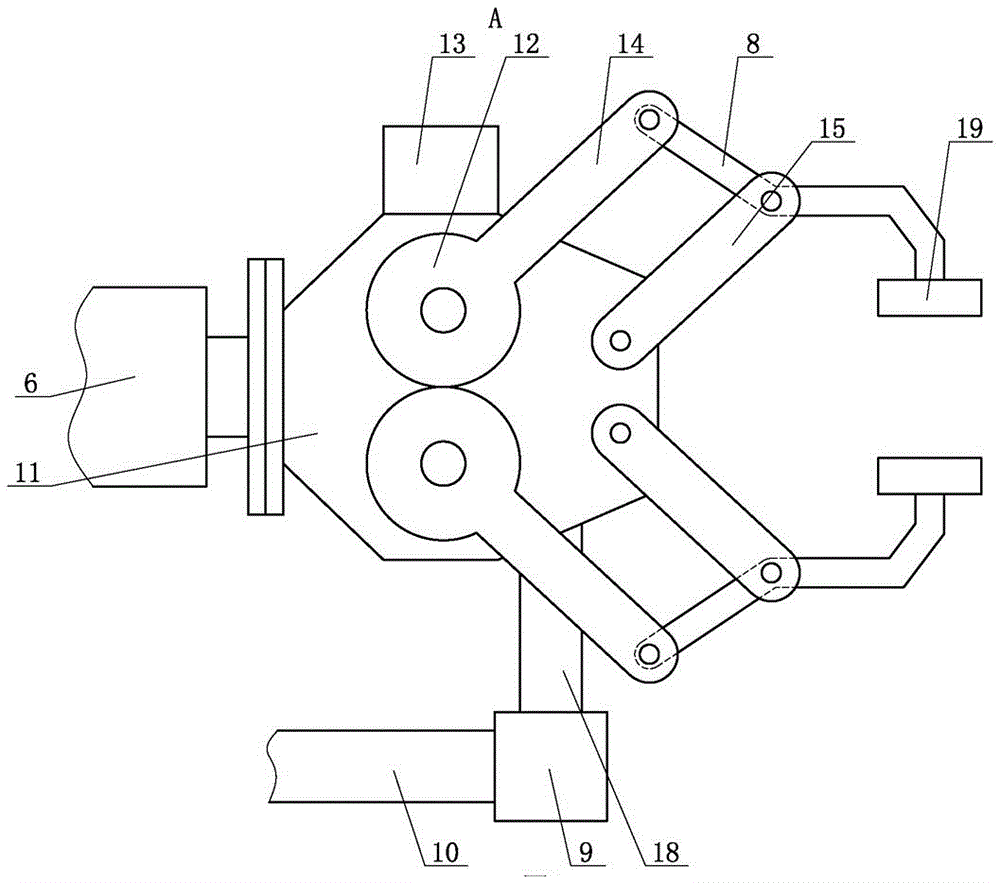

Method used

Image

Examples

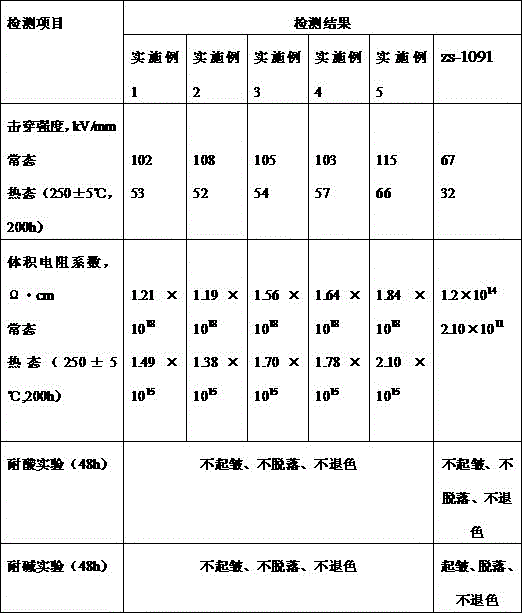

Embodiment 1

[0015] Corrosion-resistant and wear-resistant insulating paint, in parts by weight, consists of the following components: 20 parts of xylene modified phenolic resin, 30 parts of lauric acid modified alkyd resin, 25 parts of phenyltrimethylsilane, 5 parts of butyl acrylate 2 parts of kaolin, 4 parts of mica powder, 5 parts of hydroxyethyl cellulose, 30 parts of isophorone diisocyanate, 1 part of dibutyltin dilaurate, 4 parts of dioctyl terephthalate, 2 parts of hydrogenated castor oil 1 part, 1 part of cocamidopropyl betaine and 10 parts of tert-butyl methacrylate.

[0016] The preparation method comprises the following steps:

[0017] ① Add formaldehyde to xylene, add mixed acid to it dropwise, control the dropwise temperature at 30°C, reflux for 5 hours after the dropwise addition, and let it stand still to obtain a mixed solution. Toluene formaldehyde resin, the lower layer is water, remove the water in the lower layer to obtain xylene formaldehyde resin; the mass ratio of ...

Embodiment 2

[0024] Corrosion-resistant and wear-resistant insulating paint, in parts by weight, consists of the following components: 30 parts of xylene modified phenolic resin, 40 parts of lauric acid modified alkyd resin, 40 parts of phenyltrimethylsilane, 20 parts of butyl acrylate 5 parts of kaolin, 10 parts of mica powder, 8 parts of hydroxyethyl cellulose, 40 parts of isophorone diisocyanate, 3 parts of dibutyltin dilaurate, 8 parts of dioctyl terephthalate, 5 parts of hydrogenated castor oil 3 parts, 3 parts of cocamidopropyl betaine and 15 parts of tert-butyl methacrylate.

[0025] The preparation method comprises the following steps:

[0026] ① Add formaldehyde to xylene, add mixed acid to it dropwise, control the temperature during dropping at 40°C, reflux for 7 hours after dropping, and let stand to obtain a mixed solution. Toluene formaldehyde resin, the lower layer is water, remove the water in the lower layer to obtain xylene formaldehyde resin; the mass ratio of the formal...

Embodiment 3

[0033] Corrosion-resistant and wear-resistant insulating paint, in parts by weight, consists of the following components: 25 parts of xylene modified phenolic resin, 35 parts of lauric acid modified alkyd resin, 35 parts of phenyltrimethylsilane, 10 parts of butyl acrylate 3 parts of kaolin, 8 parts of mica powder, 7 parts of hydroxyethyl cellulose, 32 parts of isophorone diisocyanate, 1.5 parts of dibutyltin dilaurate, 5 parts of dioctyl terephthalate, 3 parts of hydrogenated castor oil 1.5 parts of cocamidopropyl betaine and 12 parts of tert-butyl methacrylate.

[0034] The preparation method comprises the following steps:

[0035] ① Add formaldehyde to xylene, add mixed acid to it dropwise, control the temperature during dropping at 32°C, reflux for 6 hours after the dropwise addition, and let stand to obtain a mixed solution. Toluene formaldehyde resin, the lower layer is water, remove the water in the lower layer to obtain xylene formaldehyde resin; the mass ratio of for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com