System preventing welding and installing errors of automobile part and using method of system

A technology for auto parts and assembly, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of occupying welding tongs space, increasing design difficulty, increasing the cost of fixtures, etc., to increase the working space , Shorten the design cycle and reduce the design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

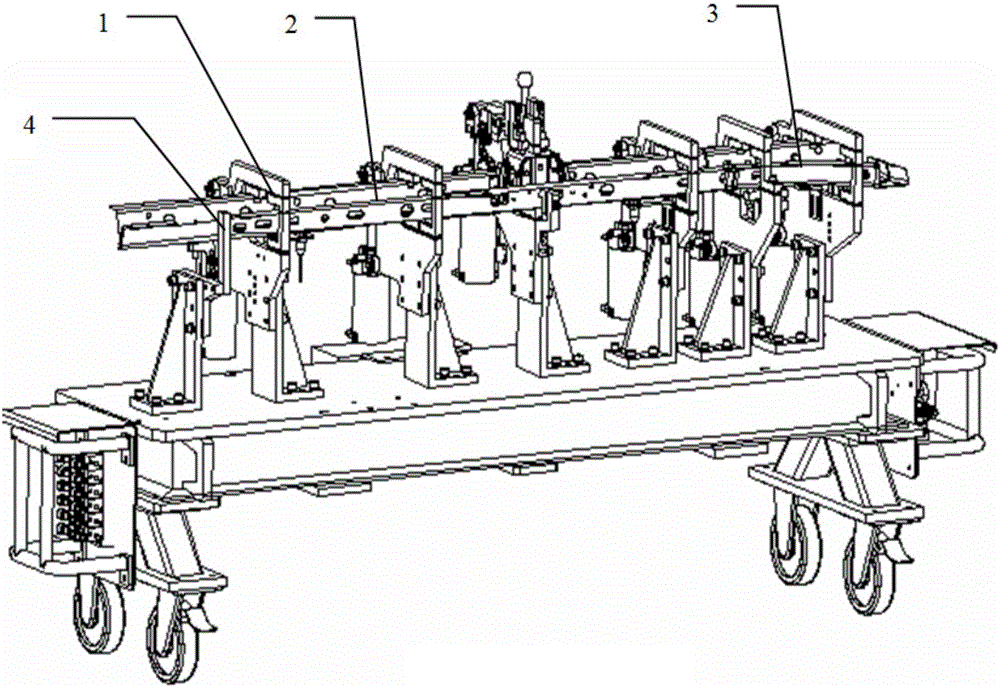

[0025] Such as figure 1 As shown, the error prevention device in the prior art is to install the error prevention limit block 4 on the positioning fixture 1. The error prevention limit block 4 will occupy a certain space, and it is easy to interfere with the movement of the welding torch. It also cannot solve the problem of wrong loading order.

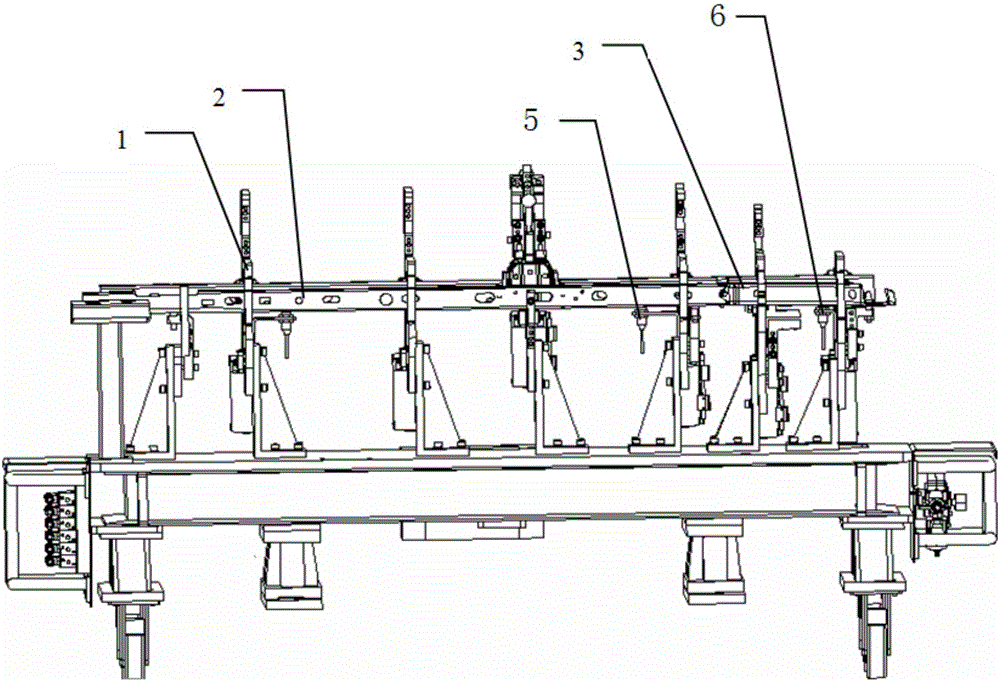

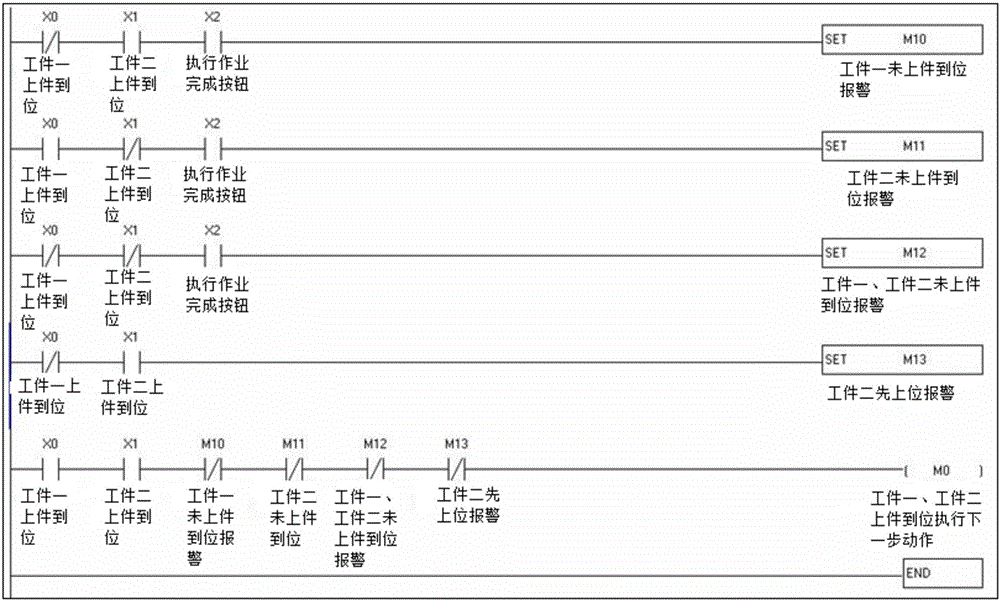

[0026] Such as figure 2 As shown, a system for preventing errors in the welding of auto parts includes a positioning fixture 1 and a controller. Sensors 1 and 5 are installed on the positioning fixture 1 where workpieces 1 and 2 are respectively clamped. and the second sensor 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com